At the end of summer, Hvide Sande Shipyard, based on Denmark’s West Coast, delivered the newbuild Nordsøen. It is the first offshore patrol vessel that combines azimuthing propulsion pods with a Hull Vane behind the transom. The investment in the Hull Vane was recovered before the ship even sailed its first nautical mile.

Hvide Sande Shipyard won the public tender to build the vessel for the Danish Fisheries Agency in late 2020. July and August 2022 were filled with sea trials, finishing touches and commissioning of systems of the Nordsøen. On August 24, the ship was named and handed over to its owner.

Also read: Hull Vane delivers its largest ‘underwater spoiler’ to date to Dutch Navy

12 to 17% less CO2 emissions

Given that the public tender awarded a lot of points on low lifecycle costs and energy efficiency, Hvide Sande Shipyard contacted Hull Vane BV during the concept design stage. Due to its length, displacement and speed range (10-18 knots), it was quickly determined that Hull Vane would provide great benefits.

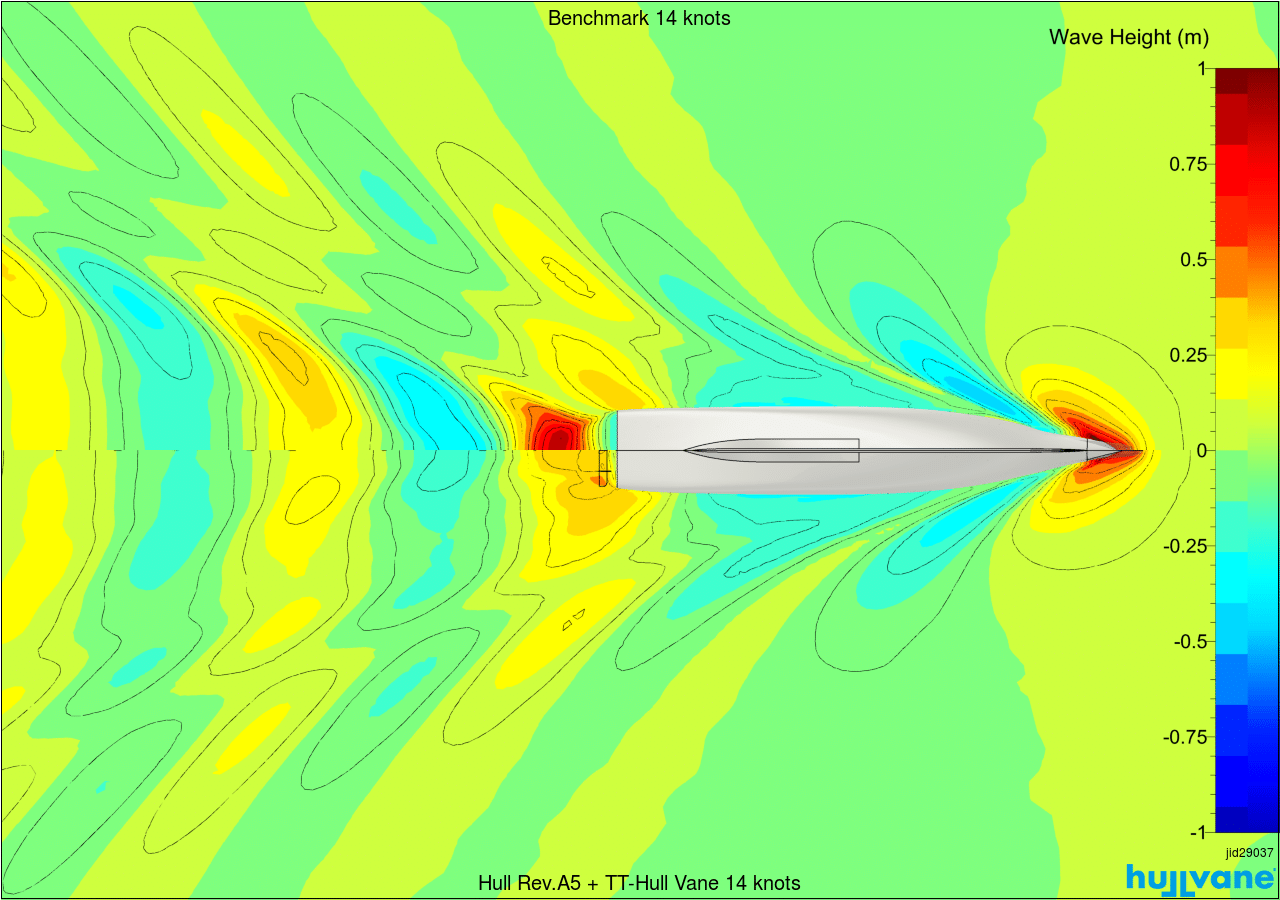

This was later confirmed with computational fluid dynamics (CFD) computations with and without Hull Vane. The resistance reduction from the Hull Vane amounts to twelve per cent at 10 knots, seventeen per cent at 14 knots and fourteen per cent at 18 knots.

Also read: Hvide Sande Shipyard orders Hull Vane for new 64-metre patrol vessel

Diesel electric pod drives

‘The project was atypical, in the sense that from the first conversation about Hull Vane up to its installation, everything was done through online meetings, as we were in full Covid lockdown-times,’ says Bruno Bouckaert, sales director of Hull Vane BV. ‘That said, the project couldn’t have run smoother. There are some interesting firsts for Hull Vane: Nordsøen is the first ship where Hull Vane is installed on a ship with azimuthing propulsion drives. The combination works perfectly, and in fact, because of the Hull Vane, the pods have to do less steering corrections in bow or stern quartering seas, which also improves their efficiency and reduces the noise level.’

Bouckaert adds: ‘Another first is the stern ramp system. On Nordsøen, the stern ramp is equipped with a slide-out system. All we had to do is make sure that the Hull Vane was out of the path of this system. We see a benefit of such systems as it allows patrol vessels and naval ships with a stern ramp to be designed with an optimal hull shape, without a lot of transom immersion. Offshore Patrol Vessels sail a lot of time at moderate speeds (5-15 knots), and then it’s really beneficial to have not too much transom immersed.’

Also read: Engine, Hull Vane and bulbous bow retrofit reduce fuel use by 24 per cent

Negative payback period

So what’s the verdict after the sea trials and several months of usage? All expectations have been met, and the vessel is said to be exceptionally quiet and efficient. The ship has never sailed without a Hull Vane, but it’s obvious that Nordsøen makes very few waves, a clear sign of its efficiency.

According to the operational profile published in the tender documents, the Hull Vane on Nordsøen saves 317,000 litres of marine diesel fuel per year. That’s enough to drive all the way around the earth every other day with a normal diesel car. The CO2 emissions are reduced by 1090 tonnes per year, at an off-the-charts low CO2 abatement cost of –212 €/tonne CO2 abated.

The reduced resistance from the Hull Vane allowed the shipyard to purchase smaller azimuthing pods and a smaller diesel generator plant, a cost saving which exceeded the Hull Vane cost and therefore reduced the total build cost. It may sound against the laws of quantum mechanics, but the Hull Vane on Nordsøen actually has a negative payback period. The investment in the Hull Vane was recovered before the ship even sailed its first nautical mile.

Also read: Video: First Hull Vane made of carbon

Making the energy transition easier

Hull Vanes have now been installed on many patrol vessels operating in the Netherlands, France, Belgium, Denmark and Nigeria. On all these vessels, the reduction in fuel consumption from the Hull Vane exceeds ten per cent. It’s a proven and very cost-effective solution for governments wishing to reduce the use of energy and CO2 emissions of their fleet, at a negative cost due to the energy savings. Whatever the fuel of the future will be, Hull Vane makes the future energy transition easier and more affordable.