In a sustainable world, shipping is desperately needed. Cargo transport by ship does not have to be dirty, it is eminently suitable for achieving the sustainable development goals. The shipping industry, especially in the Netherlands, is working hard to green the sector, says Guus van der Bles, director development at Conoship International.

This article was written by Conoship International and published in SWZ|Maritime’s February short sea special.

With the continued development of energy-efficient and even zero-emission ships, the industry is well on its way to achieving the IMO net zero emissions by 2050, according to Van der Bles.

Together with the Groninger Maritime Board, Conoship International has initiated the “Green Maritime Coalition”, which is a collaboration in the northern part of the Netherlands of knowledge centres, universities, shipping companies, shipyards, subcontractors and zero-emission technology start-ups. Participants share views and develop plans to explore the large possibilities for innovative technologies in future emission-free shipping.

This Dutch innovative industrial maritime “ecosystem” has the potential to become a major world player in developing and supplying green technologies for shipping. These green technologies provide (the northern part of) the Netherlands with very concrete tools to accelerate the reduction of nitrogen and CO2. The general goal is to reduce emissions as far as possible. The aim is to have carbon emissions reduced by eighty per cent by 2030.

Ship design company Conoship International, located in the city of Groningen in the north of the Netherlands and in the maritime capital of Poland, Gdansk, celebrated its seventieth anniversary in the maritime industry last year. With a team of 45 in-house naval architects and mechanical and structural engineers, they realise the most challenging designs and services for shipyards and shipowners from all over the world. Since 1952, over 2000 ships were built based on Conoship’s designs.

Innovation is an elemental part of a Conoship design and sets these new designs apart from existing vessels. The company is involved in numerous research projects that ensure that the ship design office remains at the forefront of developments in naval architecture and maritime technology, with a strong focus on green shipping solutions. The mission of Conoship International is to provide the shipping industry with practical solutions for low-emission or zero-emission ships.

Also read: Construction starts on new Conoship short sea shipping designs

Which green solution fits best?

The ship design office has solutions available for all sizes and fuels, suitable for both newbuild ships and modernisation of the existing fleet. ‘Because there are 80,000 cargo ships in the world, you can never replace them all before 2030. Apart from the capital destruction, it is also simply not possible to build new ships at such a pace,’ says Jan Jaap Nieuwenhuis, managing director at Conoship International.

Conoship is studying wind-assisted propulsion and developing programmes for optimum wind performance with respect to fuel consumption. Fuel savings can be between twenty and forty per cent depending on circumstances.

Together with the Conoship-related wind-propulsion specialist company Econowind BV, wind propulsors of the suction wing type under the name of VentiFoils are developed. Five ships are currently sailing with VentiFoils of up to 16 metres high, while a 20-metre version is in production and will be installed this year.

Development has also started on a 30-metre VentiFoil XL, to be produced at Bijlsma in Warten, the Netherlands. The VentiFoils can be folded in order to reduce windage in head winds and stormy conditions, while this feature also facilitates easy cargo handling. There is also a version under development where the cargo cranes can be converted into wind foils during transit.

Short sea shipping designs

For new short sea shipping designs, Conoship has a preference for diesel-electric installations. The electric motors enable the application of a large propeller diameter in combination with optimised hull lines in the aft ship resulting in the ConoDuctTail. This allows for a very high propulsive efficiency and relatively low electrical power on the propulsion motors. The combination propeller design-pitch for the fixed pitch propellor and rotations per minute (rpm) can be optimised for better propellor efficiency and minimum fuel consumption depending on speed required and the sea condition.

Conoship claims that the efficiency losses between the actual diesel generator sets and the output of the electric motors can be more than compensated by the efficiency gains in design of the aftship and a large fixed pitch propellor, which is optimised for being driven by electric motors that can handle very large torque fluctuations.

Also read: New Conoship vessel design is ready for wind-assist and future fuels

Carbon capture for LNG-powered ships

Another item on the Conoship agenda are ship-based carbon capture (SBCC) systems on LNG-driven vessels. After capturing CO2 from the exhaust gases in the funnel, the CO2 can be liquified using the cold from the liquid LNG (stored at -163°C) for compact storage on board at -20°C and at 20 bar and later be offloaded at a suitable reception facility.

In addition, the ship design company is also looking into the development of “Redox Flow” battery systems for fully electrically powered cargo ships and the maritime application of fuel cell technology and hydrogen developments.

Also read: Conoship: Marine carbon capture future-proofs LNG-fuelled vessels

Designs of energy-efficient ships

In line with the set regulations to reduce carbon emissions, Conoship has developed and designed several energy efficient ships. The first of these are already being made suitable for running on future fuels, such as green hydrogen or ammonia. By already taking into account future technologies in the new designs of cargo ships, shipping is prepared for emission-free goods transport. Below are some of Conoship’s latest designs.

Also read: Jan Jaap Nieuwenhuis new managing director of Conoship

CIP 3600, 3800, 5800

Based on extensive market research, Conoship International Projects proactively marketed its self-designed standard vessels. These innovative, diesel-electric, and environmentally friendly 3600- TDW or 3800-TDW general cargo vessels are suited for sea-river operations. The design is highly future-proof. With its well thought out diesel-electric propulsion system, enlarged propeller in combination with a ConoDuctTail and optimised hull lines, its fuel consumption will be best in class, especially in wind and waves.

To further improve its performance, the design is ready for wind-assisted propulsion, as it is prepared for the placement of Econowind VentiFoils, which would reduce fuel consumption and CO2 emissions by about ten per cent annually, depending on the sailing route.

The first clients have already ordered these new standard vessels for low-air draught sea-river operations. Six vessels are currently under construction at several shipyards. A 5800-TDW new design concept is under development and will be brought to market soon.

Lady M-series

With a deadweight capacity of 5900 tonnes, a length of 115 metres, and a dual-fuelled engine (marine gas oil (MGO) and LNG), the Ladies Marie Christine, Mathilde, Menna and Monique are designed to meet all current environmental requirements. For and in close cooperation with Wijnne Barends, Conoship International designed a truly multi-purpose vessel. The new Lady M-series is designed for transporting all kind of paper-related materials, in combination with the ability to sail “open top” and has a flush cargo deck to carry project cargo.

Bore

The latest highly fuel-efficient designs of the three 6850-TDW vessels for the Finnish owner Bore meet the flexible cargo transportation requirements of forest products in different forms. They are also able to take RoRo cargo, suitable for container transport, and can be loaded with both high and heavy as well as project cargo. The 120-metre vessels sail at a speed of around 15 knots and have Swedish/Finnish ice class 1A.

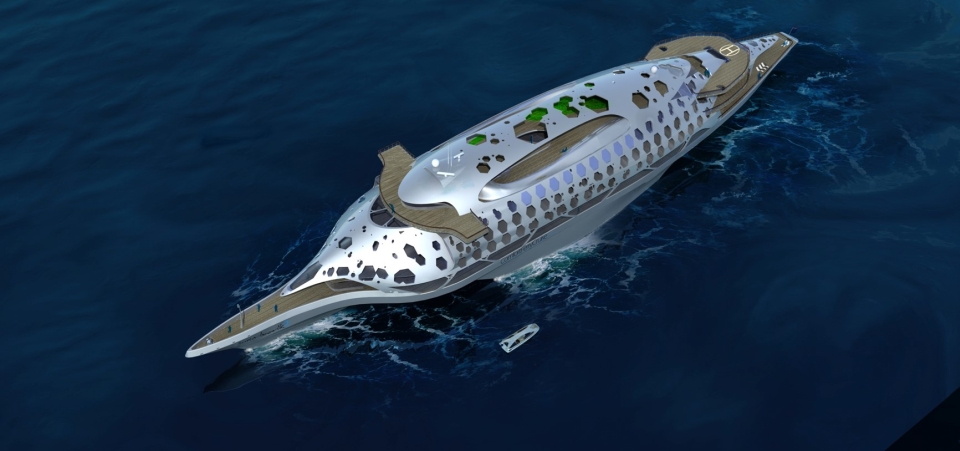

Picture (top): The CIP 3600 offers best in class fuel consumption and is ready for wind-assisted propulsion (all pictures by Conoship International).