The European Union has awarded funding to the Green Ray project that wants to develop solutions minimising methane slip from marine engines. The consortium involved will develop on-engine technologies for low-pressure dual-fuel engines, both 2 and 4-stroke, as well as a novel aftertreatment concept.

The Green Ray project coordinated by VTT Technical Research Centre of Finland brings together several companies from across the shipping value chain: shipyard Chantiers de l’Atlantique, shipowner CMA CGA, classification society DNV, the Finnish Meteorological Institute, ship manager MSC Cruises, non-profit organisation Revolve Water, engine manufacturer Wärtsilä and energy major Shell.

The proposed solutions for methane slip will be advanced to a high state of technology readiness, including demonstrators installed on two newbuilds and one retrofitted to an existing vessel. All the technologies developed in Green Ray will also be fully capable to utilise bio- or synthetic methane instead of fossil LNG.

Also read: Approval in principle for Methane Oxidation Catalyst System which targets methane slip

From cruise ships to tankers and container ships

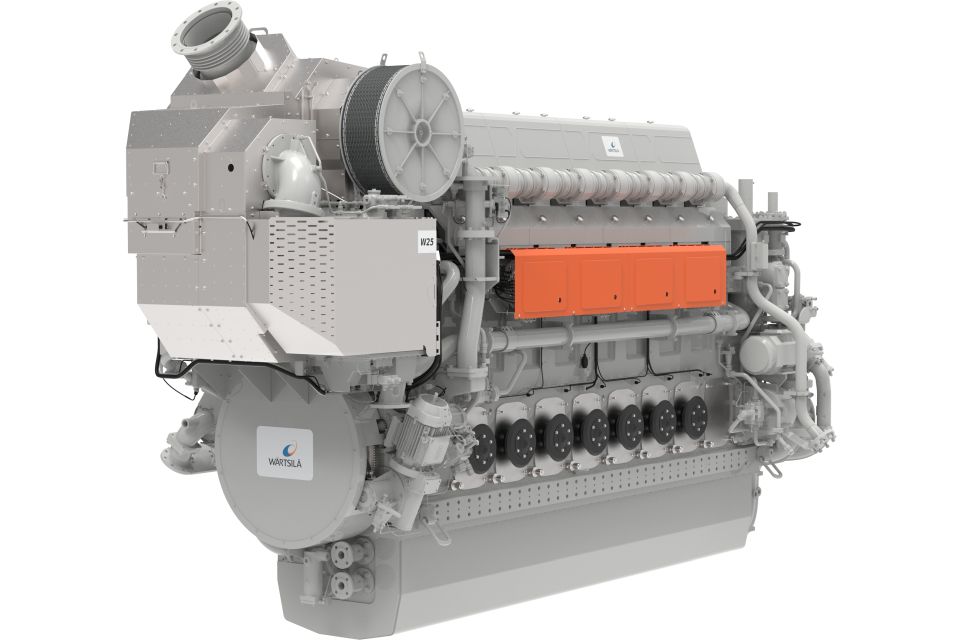

Wärtsilä will develop technology specifically for low-pressure 4-stroke dual-fuel engines that enables methane slip reduction, increases efficiency and lower operational costs at all engine loads. This technology targets the largest four-stroke engines on the market as widely used by cruise ships, ferries and gas carriers.

The engine manufacturer will also develop an on-engine technology for 2-stroke engines around a patented LNG injection system to reduce methane slip from tankers, container ships, etc. Both technologies will be demonstrated at sea in real application during the project in collaboration with the Green Ray partners.

Also read: Coalition to tackle methane emissions to minimise the impact of LNG in shipping

Methane slip prevents wider uptake

The use of LNG as a marine fuel is accelerating, driven by a well-developed supply infrastructure, a clear transition to cleaner fuels and significant air pollution and climate benefits. The issue of methane slip – unutilised and thus unburned fuel escaping into the atmosphere from engines and across the production and supply chain – is seen as one of the main challenges to wider uptake.

‘Methane slip has become an important factor in shipowners’ decisions about whether to use LNG fuel,’ says Kati Lehtoranta, Principal Scientist, VTT. ‘With these promising technologies, we aim to reduce the slip contributing directly to reduction of the total greenhouse gas emissions, opening this pathway to an even wider segment of the maritime market.’

Also read: Alfa Laval and WinGD present solution that targets methane slip

Improving the value proposition of LNG

Shell has developed a proprietary methane abatement catalyst system that has been lab tested and scaled up to a field demonstration, where it was proven to be effective not only in significantly reducing methane slip (over ninety per cent), but also in handling typical compounds that can degrade the catalyst, via the inclusion of a guard bed.

‘Shell’s climate ambition to become a net-zero emissions energy business by 2050 will require us to explore a range of avenues that have the potential to help us, our partners, and customers to decarbonise the existing LNG value chain. We are continuously working to improve the value proposition of LNG through dedicated technology research, and we are keen to develop potential solutions to minimise methane slip at such a relevant project as Green Ray,’ explains Alexander Boekhorst, VP Gas Processing and Conversion Technology at Shell.

Sebastiaan Bleuanus, General Manager, Research Coordination & Funding, Wärtsilä Marine Power, adds: ‘This research will allow us to build on the continuous improvements made in reducing methane slip from engines over the past twenty years. Taking these solutions for newbuilds and retrofits to near commercial readiness will be an important step for the long-term viability of LNG as a marine fuel.’

The project has received funding of around EUR 7 million from Horizon Europe. It will run until 2027.

Picture: The Wärtsilä 25 medium-speed dual-fuel 4-stroke marine engine (by Wärtsilä).

Also read: Is there still a future for LNG as a shipping fuel?