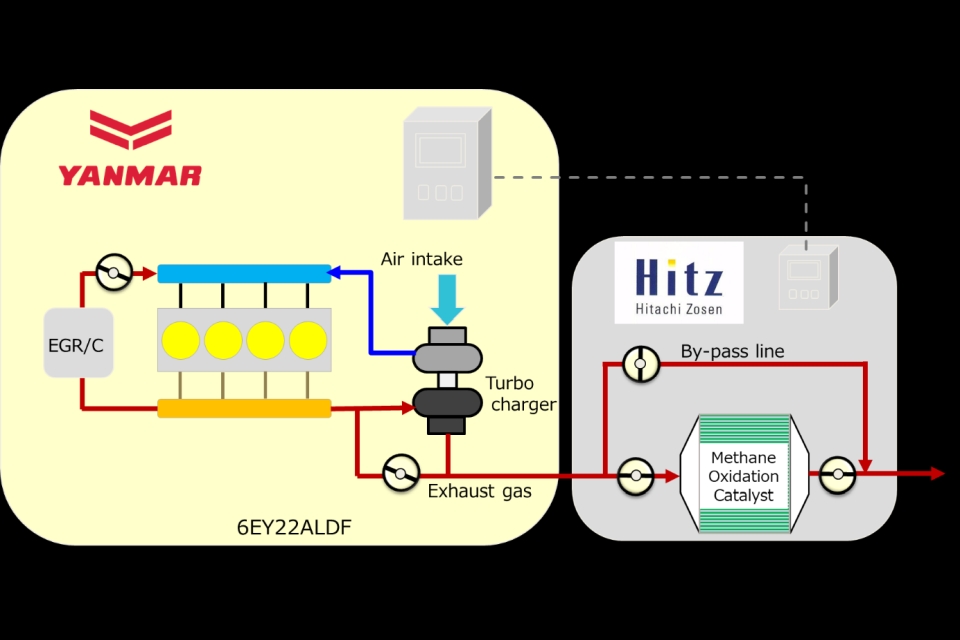

Classification society ClassNK has granted approval in principle for the world’s first Methane Oxidation Catalyst System. The system reduces methane slip by placing a methane oxidation catalyst in an LNG fuel engine and oxidising the methane.

The system was developed by Hitachi Zosen Corporation, Mitsui O.S.K. Lines (MOL), and Yanmar Power Technologies (YPT). Hitachi Zosen and YPT created the system design with MOL and Namura Shipbuilding set to build the actual demonstration vessel and design the system’s installation.

The companies are working together closely to conduct risk assessments and implement other measures. The proposed system meets the requirements of the International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels (IGF Code) and other regulations.

Also read: Alfa Laval and WinGD present solution that targets methane slip

Tackling methane slip

In gas engines, a portion of the methane in the LNG fuel is emitted into the atmosphere as unburned methane, via the exhaust. Methane has a higher greenhouse effect than CO2, and methane slip reduction is required to achieve greenhouse gas reductions.

The project aims to further reduce the environmental impact of LNG fuel engines by achieving a methane slip reduction rate of more than seventy per cent over a six-year period by combining a methane oxidation catalyst and engine improvements and verifying the design concept in actual vessels. The approval in principle is an important first step toward establishing the technology for this system.

Also read: Conoship: Marine carbon capture future-proofs LNG-fuelled vessels