The F126 frigates are one of the largest procurement projects in the history of the German navy and represent a unique and challenging project. As Dutch shipbuilder Damen won the project, we sat down with Damen Naval’s project director Frank Verhelst to find out what it’s like to be in charge of such a project.

This article was first published in SWZ|Maritime’s October 2022 issue and written by SWZ’s editor and navy expert Ir Jaap Huisman.

On 19 June 2020, the German Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) and Damen Schelde Naval Shipbuilding signed the contract for the construction of the F126. The F126 contract comprises the supply of four ships from 2028 to 2031 with an option for two more.

The frigates will be built at shipyards in Kiel and Wolgast, while the final outfitting and commissioning will take place in Hamburg at Blohm+Voss. The contract also includes logistics services and multiple land-based test and training sites.

Also read: A closer look at Germany’s true multi-mission F126 frigate of Dutch design

Multi-mission platform

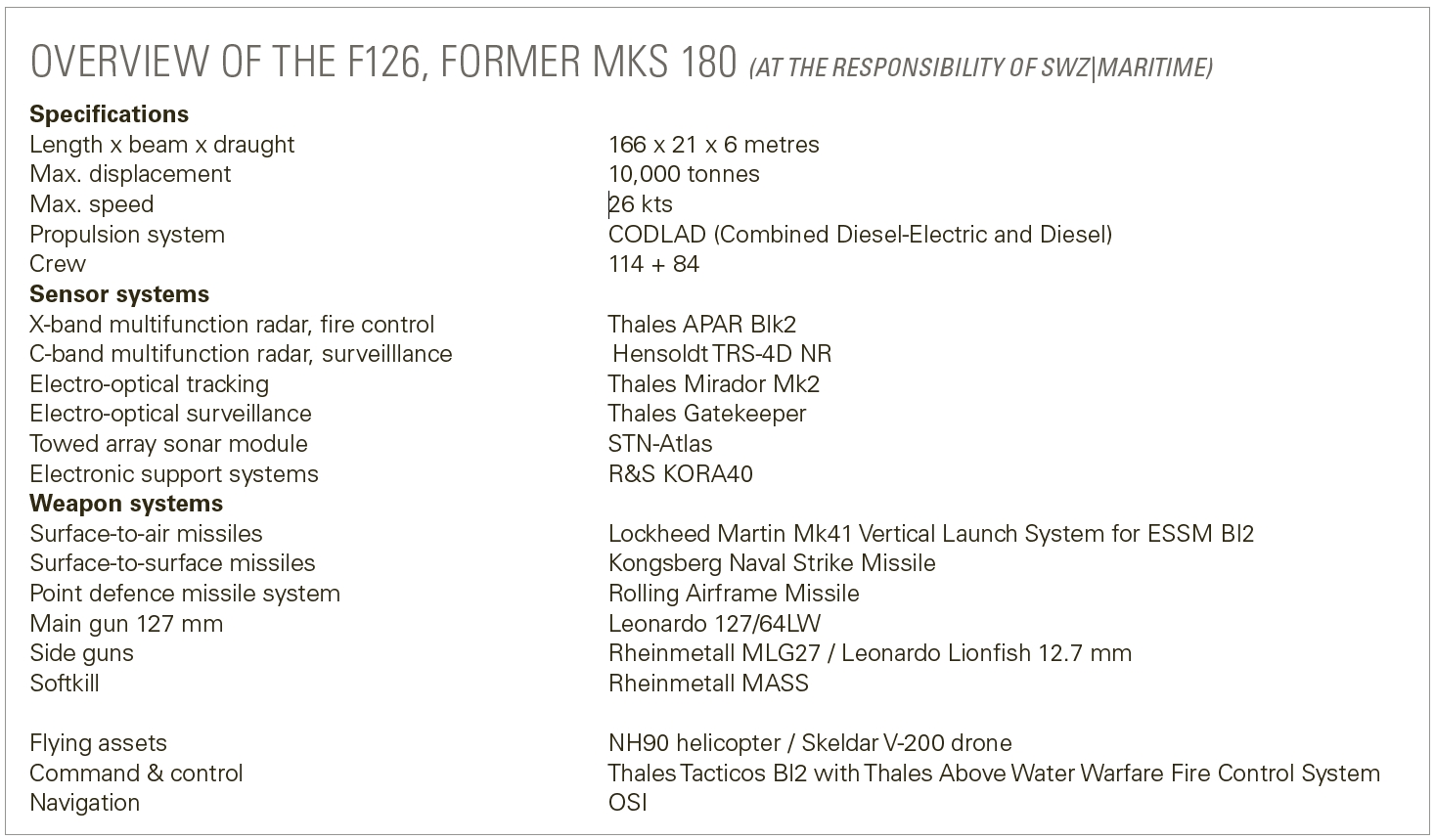

The main characteristic of this versatile frigate will be its multi-mission platform enabled by modules designed for specific military missions, such as all domain naval warfare, creation of a maritime picture above and under water, maritime surveillance and embargo control, military evacuation in crisis situations, and command of a naval task force. The ship measures approximately 10,000 tonnes, with a length of 166 metres and a beam of 21 metres. It will be one of the largest frigates of the NATO fleet.

Project director Verhelst has been working at Damen Naval for over twenty years and has ample experience in executing naval projects in the Netherlands, Indonesia and, most recently, in Mexico (a SIGMA 10514). We sat down with him to talk about the F126.

The F126 project will undoubtedly ask for an advanced project management organisation with offices in Vlissingen, Schiedam and Hamburg. Can you tell something about this and how the German organisations, such as BAAINBw and the German shipyards, are involved?

Well, basically, we started by using our standard project organisation, but found out quickly that changes were needed, both in terms of quality and quantity. We have more than 300 people working on the project, which requires an adapted version of our normal project organisation. I invested in overhead staff, something which I normally am very reluctant to do. The customer requires a lot of administration and processes, which are also needed to control the project. The project is led by a management team of three, including myself. Then there is a staff that takes care of finance, legal, contract management, project processes and support.

The project has several subprojects (or Teilprojekten in German), each one responsible for the execution of a separate part of the project. Following this, within those subprojects, special groups are assigned to carry out specific tasks. This set-up is also a consequence of the high need for coordination and interaction, internally, but also with our customer and partners.

This way of organising, assisted by a new project information management tool that was implemented for the project, enables our team to work together in a structured way, and having access and traceability to the relevant information and decisions. Of course, there is always room for improvement, which we achieve through continuous improvement programmes. As you can see, it is very dynamic, which one could expect from executing one of the most challenging naval projects ever.

When it comes to the design and engineering of the ships, could you give an indication which part Damen carries out in the Netherlands?

The complete design and engineering of the ship is being done by Damen Naval, as it is the designer and integrator, and therefore, integrally responsible for vessel performance and complete delivery. This responsibility includes performance of the platform, sensors and effectors, but also the Integrated Logistics Support (ILS) and training and test facilities.

Of course, we have many partners and subcontractors that play an important role in design and engineering. Thales Netherlands is responsible for the sensors and combat systems integration, which obviously has a huge impact on the ships’ performance. Major subcontractors have also been assigned design and engineering responsibilities. Important examples are the areas of HVAC and electricity and automation, which are being carried out by subcontractors.

They all contribute to the ship’s design and engineering, as they are an integral part of the design and engineering team. Later, the shipyards in Germany will become more closely involved as they will have to build the ships.

Also read: Germany seeks to extend F126 frigate order with Damen Shipyards

In which way are you, as the main contractor, involved in the development, production and delivery of logistics services and land-based test and training sites?

We are fully involved in all phases of logistics services and training and test facilities (so called Landanlagen). We are responsible for implementation of all requirements and correct delivery. Both disciplines are an integral part of the project, and are led by two senior project managers, both with a background in the Royal Netherlands Navy. Of course also here, this project has much involvement of our partners, and includes strong coordination with the customer as the training and test sites have to be completed on Bundeswehr bases.

As expected, the major platform systems will be provided by German industry. Renk for large parts of the propulsion system, Rolls-Royce MTU Friedrichshafen for the integral Platform Management System, Conditioning Monitoring System and other control systems. Air conditioning by Norske-Kaeser. Do you see opportunities for companies in Europe (and the Netherlands) to compete with German industry?

The project has much German content. Procurement has now been underway for two years, and many important contracts with suppliers have been signed. The Bundeswehr has the contractual right to evaluate and approve each potential supplier. Part of that evaluation is obviously overall compliance and performance, but also if it contributes to effectiveness and efficiency of the Bundeswehr. Therefore, systems can be chosen for example on the basis that they are already in use, and thus standardisation in operation, training and maintenance can be optimised.

Also read: MAN part of suppliers that provide new propulsion system for Germany’s F126 frigates

Is the working language in the project German or is English allowed?

The contractual language is German, which is mainly used. In some areas where English is the industry (and Bundeswehr) standard, this language can also be used. There is of course an additional challenge in this.

On the other hand: this is also why Damen Naval has been successful on the export market. Despite our limited size and not being able to enjoy the political and governmental levels of support that other naval shipbuilders have the benefit of in export projects, we need to adapt to this situation and create our own additional strength. In this project, for example, by investing in German language training, and by hiring many engineers and specialists from Germany, who contribute greatly to the project.

I assume there will be high standards of quality assurance that also apply to all of the many subcontracts in this bi-national project. Did that lead to changes to your system of operations?

Yes, we have to follow the standards and processes of the Bundeswehr. As many of our subcontractors have experience in how to deal with this, we know what we have to do. Basically, our systems are fit to deal with the project, however, as it is a large and complex project, there is just a lot of quality assurance needed. That is new for Damen Naval and one of the challenges we face.

On the other hand, by learning from this project, we are better prepared for future complex projects, both in the Netherlands and abroad.

Also read: Rolls-Royce will supply mtu Naval Gensets for Germany’s F126 frigates

The same probably applies to risk management and mitigation. Perhaps quite new for Damen? Did that lead to adaptation of the risk management processes?

Risk management has always been an important part of our projects, especially in our export projects, where we are always responsible for the delivery of a fully working naval vessel. What is new here for Damen Naval, is that the client has a very proactive attitude towards risk management. It is a standard item discussed at project meetings with the customer, and strict reporting processes have been implemented.

Also here, the size and complexity of the project result in many more potential risks and mitigating actions. As a project director, this is one of my priorities: I really want to understand the risks, and have my colleagues proactively manage mitigation actions. We have hired a new risk manager, to manage this process. She has been very successful in putting this on everyone’s agenda.

One remark: a project without risk does not exist. It is also one of the more demanding and rewarding parts of the project, to see risks being successfully mitigated and managed.

Ever more attention is being paid to cyber security, this aspect could be outsourced to Thales and others, but how do you handle such a complicated and comprehensive subject as main contractor?

It is the same as all the other aspects of the project. Damen is fully responsible for and leading this subject. However, as you can imagine, this is a fast changing world, with fast changing requirements. We are implementing processes and structures on how to implement cyber security throughout the project (both in the office and on board of the ships).

Also read: RENK to supply gearbox and electric propulsion motors for German F126 frigates

Every industry in the Netherlands has difficulty recruiting qualified personnel with preferably some experience. Has the project been able to recruit sufficient staff?

I can say that we have been successful in hiring new staff. Our HR department really did a remarkable job there. For someone interested in working on naval projects, this project is as challenging as a project can be. Therefore, we manage to attract many young, but also experienced people who would like to be part of it. Some specialists are hard to get, as they are scarce in the market. Here we rely on specialised companies to help us, also using our office in Hamburg as a forward presence.

One observation: due to Covid-19, we have become used to working remotely, therefore offering many of our employees more flexibility from where to work. This is not possible for all disciplines, but many colleagues can work either from one of our offices, or even from home. I believe that this makes us more attractive as an employer.

By now, you should have experience in collaborating with German organisations and industry. There are, however, some cultural differences. Have you experienced any hindrance?

No, compared to projects in Indonesia and Mexico, this is as culturally close as it can get. Of course, we sometimes discover our differences, but they are easily overcome and more than compensated by our shared values and similar ways of doing things. Furthermore, here we are investing in the, I would say, softer side of project management: teambuilding, social gatherings and taking more time to explain what we mean.

What is your experience with the more comprehensive and detailed German Naval Rules?

They are the German Naval Rules, and therefore we implement them. The project has room to “tailor” rules and regulations. That means that where not executable, practicable or where there are conflicts, we have the structure and process to decide together with the customer how to deal with those. From my point of view, the rules are basically not that different from those the Dutch Ministry of Defence and the Royal Netherlands Navy use. But of course, here as well, the devil is in the detail.

We are interested in the planning: is there a date yet for the start of steel cutting of the first ship?

Yes of course, steel cutting is planned for the second half of 2023. A specific date will be communicated as soon as possible, but as shipbuilders, we are all looking forward to this moment. Here, we can really change the project from (digital) paper to steel!

Picture (top): Damen Naval’s project director Frank Verhelst posing with a model of the F126 (from SWZ|Maritime’s October 2022 issue, by Damen).