Oil and Gas Climate Initiative (OGCI) and Stena Bulk studied carbon capture and storage on ships and found it is technically feasible. However, it comes at a price. The study found capital expenditure (capex) for a system that captures ninety per cent of CO2 could amount to about € 29 million, while operating costs increase by 25 per cent.

The study, launched in October 2020, investigated the potential of capturing carbon from the exhaust gases of the large internal combustion engines that large ships predominantly use for propulsion. Using a SuezMax ship, considered the most challenging use case, a range of factors including energy balances, fundamental physics and integration challenges were assessed.

The study’s findings demonstrate that marine carbon capture can play a role in meeting the International Marine Organization’s (IMO) 2050 target of reducing emissions from the industry by fifty per cent compared to 2008 baselines. The decarbonisation of shipping is a critical part of achieving global pathways to net zero. Transportation contributes 24 per cent of global energy-related greenhouse gas emissions and around ten per cent of that total comes from international deep-sea shipping.

Also read: ‘Reducing shipping emissions starts with wind power and carbon capture’

Energy demand should be focus for R&D

For the study a large oil tanker was used as a test case to adapt carbon capture technology for use onboard ships. The process appears to be technically feasible with no major barriers emerging during the course of the study. Since the oil tanker was powered by a highly efficient, two-stroke engine with low energy availability in the exhaust gas, the test case represents one of the most challenging applications and leads to an increased consumption of fuel to power auxiliary engines and an oil-fired boiler that delivers the necessary energy to run the capture system.

Optimisation of the engine and/or waste heat recovery units to be more compatible with a carbon capture system may reduce the need for additional fuel consumption. Vessels using engines with more waste heat availability may prove more feasible with the system as designed. Developments in carbon capture technology that reduce the carbon dioxide separation energy would have a significant impact on energy demand and this should be a primary focus for research and development teams, according to the study.

Capex of carbon capture and storage

Although technically feasible, the study found that high operational and capital expenses would be involved in any deployment. OGCI and Stena Bulk have provided initial estimates for these numbers. The capital expenditure (capex) estimate was built by analysing the current individual costs for the main components needed in the carbon dioxide removal, liquefaction and storage processes.

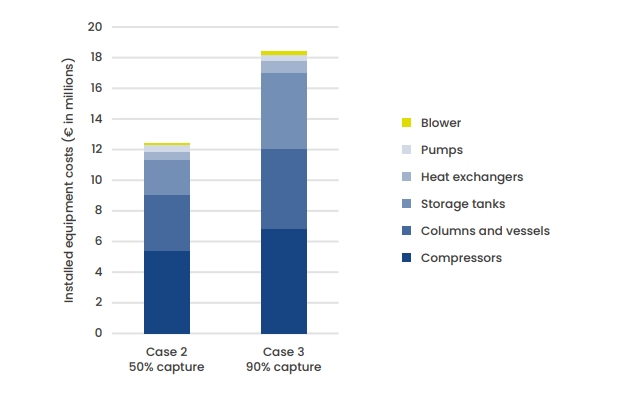

The figure below shows a breakdown of these equipment costs based on information provided by AspenPlus’s Aspen Capital Cost Estimator v11. The storage tanks, although not complex, contribute significantly to the costs. Volume production to meet widespread industry demand would likely lead to reductions in these component costs, but the magnitude of such reductions is difficult to assess.

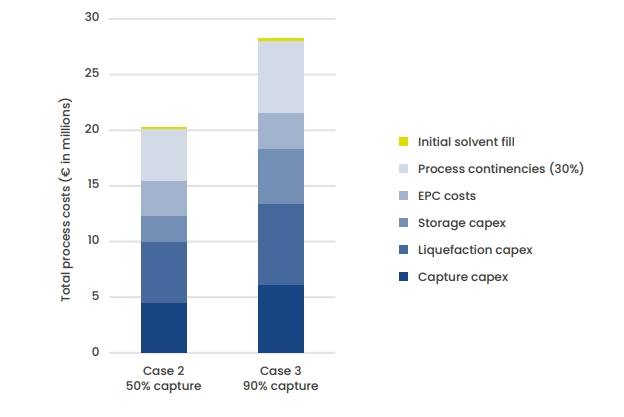

Component costs are not the only contributor to overall capital expenditures and the next figure shows the estimated costs when engineering, procurement and construction (EPC) and contingency costs are included.

Operating expenses

Operating expenses are equally important and the impact of the excess fuel burned can be substantial. The following table provides a breakdown of estimated fixed and variable operating expenses for a system that captures fifty per cent of CO2 (case 2) and one that captures ninety per cent (case 3). The variable expenses associated with producing the additional energy for the capture system dominate and the total numbers add nearly thirteen per cent and 25 per cent to a reference vessel’s existing operating expenses.

Costs should be addressed

Commodity prices for captured carbon dioxide may offset some of these costs, but this is difficult to assess without clear guidance on regulations governing carbon pricing. As the marine industry sets course for 2030 with an ambition to meet the IMO targets for greenhouse gas emissions, other carbon reduction technologies are likely to remain more attractive.

It may be more appropriate to compare marine carbon capture to other solutions requiring long-term investment and infrastructure build-out, such as ammonia and hydrogen. By 2030 more mature networks and infrastructure to process and sequester large volumes of carbon dioxide are expected to be in place. Regardless, if the costs of marine carbon capture can be sufficiently addressed, it could play an important role in a multi-pronged effort to meet the challenge of decarbonizing the marine industry.

The study recommends further work should be done to compare costs of carbon capture against other long-term marine carbon dioxide reduction technologies. The results have encouraged the research team to pursue a demonstration to validate their assumptions and uncover further opportunities.

In the meantime, other companies have already made a start with carbon capture and storage, such as Wärtsilä, which installed a pilot plant to test carbon capture on board ships back in March and plans to retrofit a tanker of Solvang with such a system. Alfa Laval and NMRI trialled using a scrubber to capture CO2 on board a ship. Some shipowners expect there will also be a market for transporting the CO2 captured on board, such as Northern Lights, which has already ordered CO2 carriers for this purpose.

Pictures by OGCI.

Also read: Wärtsilä and Solvang to retrofit tanker with carbon capture and storage / Alfa Laval and NMRI capture CO2 on board ship using scrubber / Northern Lights orders CO2 carriers with WASP and air lubrication