Panamax sloop Nilaya has left the construction hall at Royal Huisman in Vollenhove, the Netherlands, in preparation for the installation of its towering rig in Amsterdam. This highly anticipated superyacht is the first to utilize the builder’s new Featherlight design and production method.

Continuous weight monitoring throughout the build of Project 405, aka Reichel/Pugh – Nauta 154, confirms the Dutch yacht builder has achieved its goal of slicing elevent per cent of the weight of its typical advanced aluminium cruising yachts. Most importantly, it has reduced weight without sacrificing stiffness or cutting corners on quality for this high-performance cruiser.

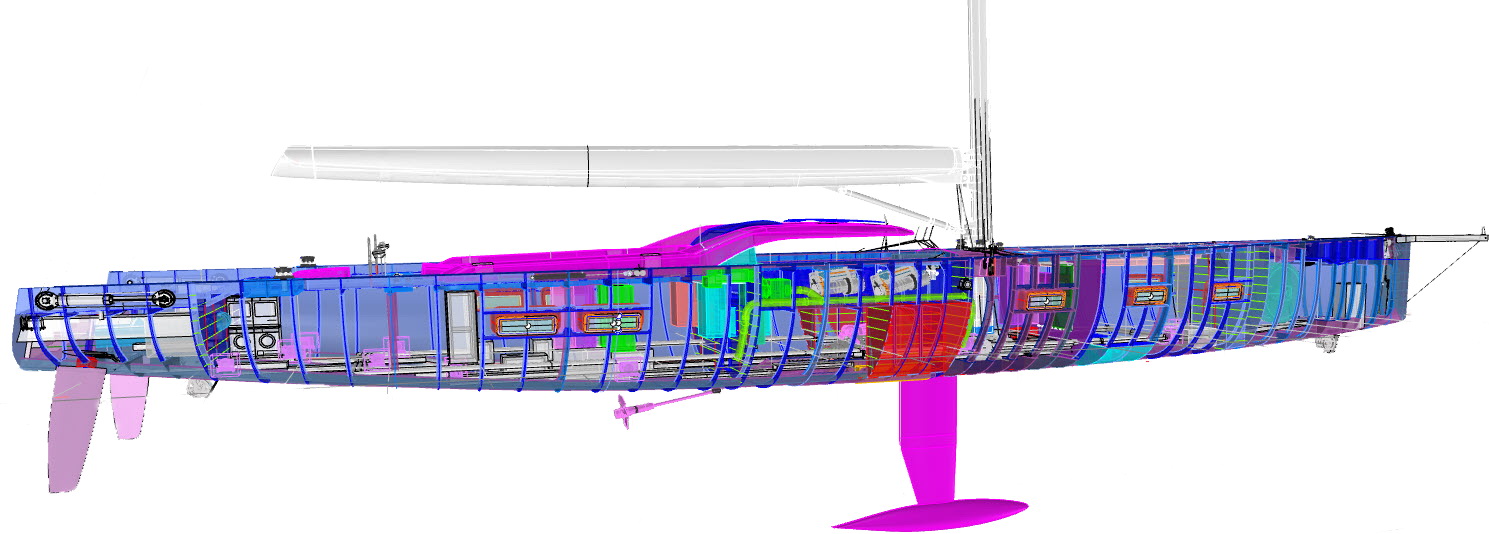

The shipyard’s revolutionary Featherlight method for this 46.8-metre/154-foot sailing machine is not a single process or construction technique, but a holistic light weight approach combining various weight-saving solutions.

Also read: Good times for yacht building – What Royal Huisman is up to

Finite Element Analysis

The Featherlight process makes use of Finite Element Analysis (FEA), a design methodology rooted in spacecraft technology. FEA modelling enabled selecting various construction materials and varied Alustar aluminium plate thicknesses and frame spacing to maximise hull stiffness while minimising total displacement. With engineering and weight management brought in-house, the approach was comprehensive, extending to lighting, insulation, and all mechanical systems.

The interior, too, benefited from careful weight analysis. All interior structural members utilize lightweight foam coring. This innovative approach narrows the displacement gap between aluminum and carbon composite yachts. Comfortable, robust characteristics of an aluminum yacht are now a viable option for owners seeking true sailing performance.

Carbon composite

Capturing the carbon fibre expertise of its sister company Rondal, Royal Huisman’s engineering team used this synergy to analyse and predict which structural components would be best made of composites or aluminium. For example, the entire 17.5-metre curvaceous coachroof and guest cockpit structure are carbon composite.

Likewise, the recessed tender well on the foredeck (that transforms to a seating area for cruising or a flush deck for racing) is also carbon composite as are a watertight bulkhead, crew entrance, twin rudders, the keel trunk and a cockpit bimini hardtop.

For any high-performance cruiser, a carbon fibre mast, boom, and standing rigging are critical to keeping weight as low and as centred as possible for optimal balance. While Rondal has considerable carbon spar expertise, bringing the design of this component — and the sailmaker – into the process during the larger hull design phase is a page out of a maxi-racer’s playbook.

Also read: Royal Huisman unveils 100-metre sailing yacht concept Wing 100

Structured luff sail

Project 405 is also the first yacht of this size range designed to take advantage of structured luff sail design pioneered by Doyle Sails, a choice that allowed the entire Rondal mast, rig, and components to be lighter — a key point considering her Panamax air draught.

To take advantage of the very narrow headsail sheeting angles possible, Rondal created a radical new curved carbon fibre spreader design that is both shorter and more aerodynamic than anything previously available. Rondal also supplied new generation hybrid (carbon and aluminium) captive winches, hatches and various sail handling gear. Most deck hardware is titanium.

Suitable for superyacht regattas

Nilaya’s racy, low profile with its straight bow, wide transom, and twin rudders, echoes the look of its owners’ previous highly successful maxi-racer of the same name. It is from the boards of the same naval architecture and design firms, Reichel / Pugh and Nauta, both firms with impressive reputations for high-performance sailing yachts.

Exploring all the options for a luxurious performance cruiser also capable of podium finishes at superyacht regattas, the team made full design studies for the yacht in both carbon and aluminium using computational fluid dynamics (CFD) to optimise hull shape and balance. Royal Huisman’s Featherlight method, an evolution of nearly sixty years of aluminium yacht-building experience melded with the latest carbon technology, provides the owners with the best of both materials for a no-compromise yacht.

Also read: Royal Huisman delivers laser-lit superyacht Phi

Paving the way

‘The success of the innovations with Project 405 paves the way to use this bold new approach for future builds,’ says Royal Huisman CEO Jan Timmerman. ‘I am proud of the investment we have made in advanced engineering and of the way teams from Royal Huisman and Rondal advanced new solutions to meet the brief from very knowledgeable clients and designers. The owners as well deserve congratulations for pushing everyone to achieve just a little bit more and for encouraging innovation at every step. Nilaya will be the world’s lightest aluminum sailing superyacht for her length: she rewrites the script for high-performance superyachts.’

Royal Huisman Project 405 Nilaya will be delivered in the coming months.

Picture (top) by Tom van Oossanen.