Yacht building is in a comfortable market position. Various shipyards are reporting a good first quarter. Royal Huisman in Vollenhove has already chosen a specialisation and has a healthy order book containing at least six projects. Royal Huisman’s innovation team gives a sneak peek at what they are working on.

This article was written by SWZ editor and freelance maritime journalist Sander Klos and was originally published in SWZ|Maritime’s September 2022 yacht special. Klos visited Royal Huisman to see what this Dutch super sailing yacht builder is up to.

Various domestic (Dutch) and foreign shipyards are reporting a good first quarter. Yacht builder HanseYachts saw its order book double in the first three months compared to last year. And in the Netherlands, Wim Beelen has ambitious plans for a yard in Amsterdam (ADM site) and Balk Shipyard in Urk wants to specialise in yacht building in a new harbour near Urk on the IJsselmeer.

Four yachts were under construction at Royal Huisman in June. And here too, things have changed since SWZ last visited. For a year now, the yard has been working with an innovation team and a “five-slice pie chart”, consisting of the spearheads sustainability, Featherlight, sailing systems, user experience and tools and methods.

Also read: Royal Huisman unveils 100-metre sailing yacht concept Wing 100

Choice of sails

In addition, Royal Huisman opts for sailing yachts without a doubt. ‘They are more fun to travel from A to B, while motor yachts have the looks to be in A or B,’ the yard says.

Is that, combined with the use of free wind energy, enough to book extra sailing yacht orders? According to Van ‘t Verlaat, that is exactly the story with project 410, the 85-metre “New World Sloop”, which is also considered to be the world’s longest single-masted yacht. Because measured across deck, it is four metres longer than record holder Athena.

On board, much attention is paid to green and silent energy. Rondal designed the carbon mast and boom and sailing system. ‘The client chose this, while many of his friends have motor yachts.’

On another yacht under construction, project 405, lighter materials, if class regulations allow it, will bring weight savings of up to eleven per cent.

Also read: Royal Huisman delivers laser-lit superyacht Phi

Fishing boat

But Royal Huisman is not averse to motorised craft either. A striking example is project 406, a six-deck, 52-metre sportfish boat. ‘It is our first sportfish yacht and the client could not find another yard willing to take on the project. So we started the design from scratch.’

In the construction hall, aluminium hull and superstructure lie side by side. The reporter looks doubtfully at the ceiling. ‘They put the superstructure on for a short moment and found that some eighty centimetres up to the ceiling remained.’

The other motor yacht – with two modest masts – in the order book is in fact a refit, but so radical that the shipyard refers to it as a newbuild. This Atlantide from the 1930s will be completely overhauled and restored in two years’ time for an American owner.

‘Plenty of demand’

Van ‘t Verlaat is familiar with Wim Beelen’s plans to establish a superyacht yard at the ADM site in Amsterdam and knows that Balk in Urk wants to focus entirely on building yachts. ‘There is enough demand and all those yachts require the necessary annual maintenance. The more supply, the more Dutch expertise. On the other hand, they could of course also become competitors when the market shrinks.’

Royal Huisman, its subsidiary Rondal in Vollenhove and Huisfit in Amsterdam employ over 300 people on a permanent basis, as well as a diverse group of co-makers and trainees. ‘It’s harder to get new personnel. We now have fourteen vacancies, which is more than we used to have on average.’

Innovative duo

In Huisman’s working method, client teams submit the wishes of the client(s) to innovation teams to see what can and cannot be done. Jidde Looijenga and Hermen de Jong make up the innovation team, which for special questions can rely on specialists in the organisation. That is why we asked them a few questions.

What innovative propulsion techniques are used in projects 404 to 410 (such as the foam-cored interior of project 405)? I can imagine that the choice for a certain fuel leads to different constructive requirements. Whereas the application of various innovative fuels is a choice in itself. And what consequences does the fuel choice have for hardware like propulsion units, batteries and fuel cells?

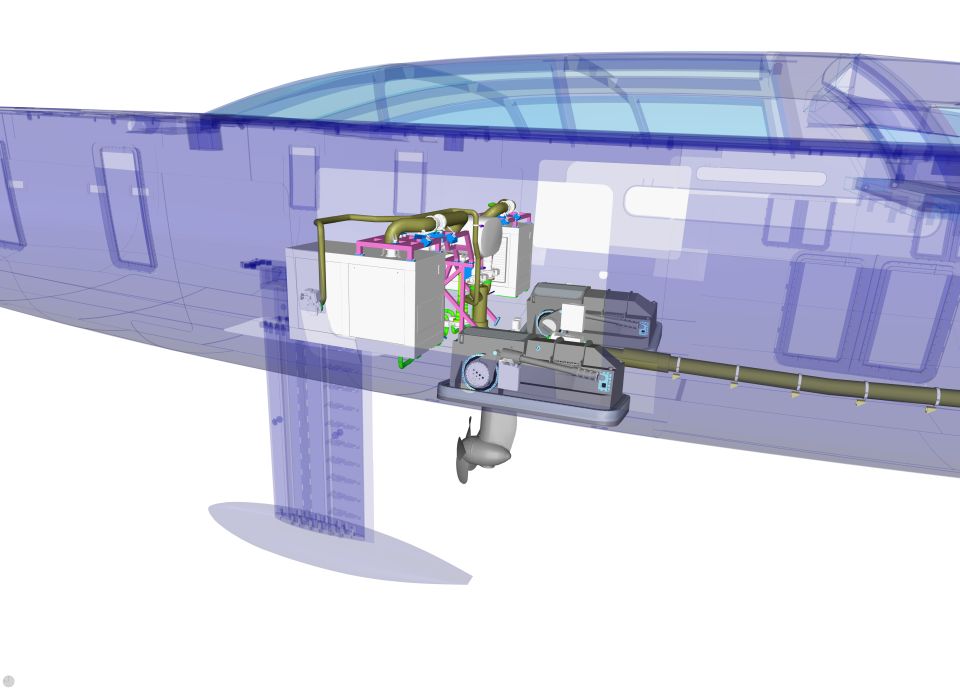

Innovation managers De Jong and Looijenga: ‘To a greater or lesser extent, all our newbuild projects use hybrid propulsion, regeneration on the propeller and winches, and large battery packs for peakshaving and quiet times. Sailing yachts also use a lot of hydraulics and we have created solutions that fit into our hybrid energy concept. The result is more comfort, more redundancy, more flexibility and lower fuel consumption.

What seems to be the ideal – holistic – solution (the holy grail)?

De Jong: ‘For the near future, we conducted a broad feasibility study into possible sustainable fuels and their suitability for our yachts. We focused on non-fossil and emission-free solutions. What the future solutions will look like differs per yacht and per type of customer and they can consist of a combination of batteries, hydrogen and methanol. In our opinion, all solutions always go hand in hand with increased awareness of energy consumption and reduction of energy needs. The big advantage of sailing yachts is that they can generate their own energy and that makes the solutions we work on rather unique.’

Also read: Student visit to Royal Huisman: ‘Hybrid yachts are a market for the future’

Do clients really order “greener” ships? Apart from dimensions and comfort (Featherlight), what are the important drivers? Does the (future) crew also have a say?

De Jong: ‘As can be seen from the solutions in our newbuild yachts, hybrid and electric propulsion are now self-evident for customers and for us as a shipyard. Indeed, the crew, be it the captain, the engineer or the chief officer, often plays a major role in determining the intended use and layout of the yacht.’

Van ‘t Verlaat (PR & Communications): ‘Sometimes the obvious is not so obvious at all, like the large amount of energy available on the ocean: wind! Many of our yachts are therefore already very “green and sustainable”. It surprises us sometimes that the majority of superyachts worldwide are not yet propelled by sails. Wind propulsion will always surpass the energy consumption of motor yachts. Moreover, wind energy is “free” – of gases, costs and noise. And sailing is fun, too… We expect that more and more motor yacht owners will switch to a yacht that uses the wind.’

In your spring newsletter, you say that fuels of the future and reusable materials ‘are being researched’. What does that look like in practice? Who are you working with, where do you find knowledge about these new materials?

De Jong: ‘We research new materials and fuels together with partners such as potential suppliers, knowledge institutions and architects. Where necessary, we build prototypes that we test to prove their performance and gain new, practical insights.’

What developments do you see coming for the sailing systems on board?

De Jong: ‘The current rigs are high tech and will continue to interest performance-oriented customers. We expect that a group of customers will emerge that is interested in more accessible sailing systems: simpler in form, more freedom of design for the yacht, cheaper to buy and use, quickly deployable and easy to automate.’

Things are also changing in tools and methods.

De Jong: ‘We have developed algorithms that enable extensive structural optimisation. This has allowed us to save up to eleven per cent of aluminium hull weight in recent projects.’

‘Other weight savings result from hybrid constructions, in which we make large structural parts such as the castings for the keel, superstructure and cockpit in carbon fibre and integrate them with the aluminium hull. For these and other applications, we have researched a lot of constructive and flexible adhesive connections.’

Picture (top): Racing with the Aquarius. It was designed by Dykstra Naval Architects and measures 56 metres overall and 41 metres on the waterline, which gives it a hull speed of sixteen knots. With its draught of 4.8 metres, it won’t compete on the IJsselmeer.

SWZ’s yacht special

Our digital archive is once again available to subscribers and they can read the digitial version of our September yacht special there. Subscribers can register here to gain access. Not yet a subscriber? Visit our subscription page.