Companies highlight their own activities or let themselves be interviewed by journalists. For SWZ|Maritime’s September special on (super)yachts, we joined a teacher and two students of shipbuilding who visited yacht builder Royal Huisman. What do the students think about a career in yacht building and what trends and innovation is Royal Huisman working on?

They have already been there two years ago, but now the press is watching. Amy Spijkerman, Guy Fleury and their teacher Harmen Terlouw from the Maritime Institute Willem Barentsz (MIWB), part of NHL Stenden University, came to talk and look around at Royal Huisman shipyard in Vollenhove, the Netherlands. The hosts are Stefan Coronel, manager Design & Engineering, and PR man Jurjen van ‘t Verlaat.

When Coronel asks which direction both students want to take, Fleury says without hesitation: ‘Photography’. But as far as the shipbuilding profession is concerned, he is more into ‘design’. Amy in turn is more into constructions and especially ‘how to make them lighter’. She can see herself working in yacht building. ‘You broaden your thinking and there is more room for initiative than when I was a trainee and helped to convert an animal carrier into a cruise ship. This project was very straightforward.’

By ourselves and together

When it comes to making constructions lighter, Coronel is right person to talk to, because Royal Huisman invests time and money in the search for lighter and yet strong constructions. This has to do with both the method of construction and the choice of materials. And there is also the balance between the knowledge you want to have yourself and the knowledge you attract from elsewhere.

‘We have the five main disciplines for superyacht development in house: construction, deck, systems, electrical/system integration and interior. We have in-house specialists in critical areas of knowledge, but we also outsource a little more to “niche” experts, for example in fast-moving fields such as navigation and communication. In other areas, we innovate in cooperation with our sister company Rondal and with external partners, for example in sustainability and energy management. An excellent step in this respect is peak shaving, which prevents extremes in energy consumption, allowing us to use smaller generators and engines. The next step is to reduce the total energy demand by using hybrid systems or energy recovery, which makes it possible to use only the batteries at night and to sail on your batteries for a few hours, depending on the installed capacity.’

Spijkerman: ‘Are you aiming for zero emissions?’

Coronel: ‘For the company itself, we are moving in that direction, but for the customer it is a matter of guiding and advising. So that the client will consider what is useful when he wants to sell the ship in ten or fifteen years’ time.’

‘We want to develop sustainable systems that we can sell during refits. We already have experience with conversion from traditional to hybrid propulsion and this could be a new market for us. Although space is often limited during refits, especially if you have to install extra batteries.’

Lighter first

In yacht building, reference is often made to “class” and “flag”. Coronel: ‘A yacht is in fact a collection of exceptions to these rules. Cargo ships, for example, can be considered as a beam in terms of length with respect to strength calculation, whereas we work with all kinds of decks and differences in heights, thicknesses and profiles. That demands a different approach to structural design.’

‘In the pursuit of lighter construction, we have brought that part of the design process all the way forward and partly automated it. In this way, even before the construction is designed further, we have a good idea of where the geometry will be most heavily loaded. This knowledge can easily save up to ten per cent in weight, by making a frame thinner or higher and thereby increasing the stiffness. We also make more use of carbon for hatches, deck, superstructure and the keel trunk. Our hulls will still be made of milled aluminium, but we are also looking at other compositions.’

Staff shortage

In between, Coronel asks about the study position of both his guests. Fleury reports that he is graduating on a project whereby a punt will be pod driven. ‘By removing the diesel engine and the lead ballast, no extra lead ballast is needed any more when using batteries’.

Spijkerman is currently doing a premaster at TU Delft and is still looking for a good graduation project. Whereas Fleury says he is being approached (‘by four companies’), Spijkerman has to look for herself. Coronel indicates that there is ‘a shortage of personnel, also around us’.

He adds: ‘We find people in two ways: in the field of engineering, we want to retain good mbo, hbo or university trainees and we visit symposia such as those organised by Froude or other educational institutions. School pupils/students and potential customers are, in fact, the only groups to whom Royal Huisman gives tours around the yard. We get senior staff from our network.’ Of the 285 or so employees, about five per cent come from abroad.

E-motors

Coronel does believe that Royal Huisman is one of the largest builders of super (sailing) yachts worldwide. ‘A super (sailing) yacht is a good way to innovate. Clients may have become wealthy by not spending too much, but if they find it useful, beautiful and unique (“greenest yacht in the world”), often there will be a budget for it. A big advantage is that you can immediately put an innovation that has just come out of the lab into a yacht. We are also working with a cluster of companies that have similar issues concerning energy use and recovery.’

Among the research areas is the development of small and reliable e-motors. ‘Small and with a lot of power considering their weight. We apply a system with the permanent magnet motors, like they use in the Formula E cars. These are pretty small things that can absorb energy from the propeller shaft on board and also deliver it back. The temperature development does require the necessary attention, because where a racing car brakes for a few seconds at a time, the propeller shaft rotates for hours at a time.’

Trendy

Coronel has been around for some years. What trends did he see and is he seeing in yacht building?

‘Lately, “lighting things” in laser as a successor to LED have been important and there is always interest in parts that can be folded out of the hull. In sailing yachts, there is a trend towards modern and sleek on the one hand, but also towards retro on the other. And in both cases, green energy concepts play a bigger role.’

Also read: Royal Huisman wins contract for 65-metre sailing yacht

Research assistance

When Terlouw asks whether Royal Huisman is working on hydrogen, Coronel’s reply is affirmative. ‘We are working on the future application of this in sailing yachts and are also in consultation with Lloyd’s. In terms of the space required, hydrogen is easier to use for large motor boat builders. We are following the developments closely as part of our research into energy concepts.’

Terlouw immediately forges ahead: ‘I do have a student who is interested in such research.’ Coronel does not immediately jump at the opportunity. ‘We are also currently conducting two other important studies: one into even lighter construction and the other – together with Rondal – into more innovative sail systems. In the former, we are ” squeezing out ” the weight. We are staying in aluminium, because it is a great material and infinitely reusable. In contrast to carbon with its thermosets. In addition to well-known materials such as Alustar 5059 H321, we are testing other alloys, such as scandium. We have noticed that there are still steps to be taken in this field by class, and not all operational aspects are completely clear to us yet. But these new alloys offer more tensile strength and can therefore be used more lightly.’

‘With the second research project we are responding to wishes for better handling. Some owners find sailing rigs with many lines and stays difficult, so we are looking at unstayed masts, for example. Such simple systems can be used on motor yachts for sail support, which can easily save twenty to thirty per cent of fuel.

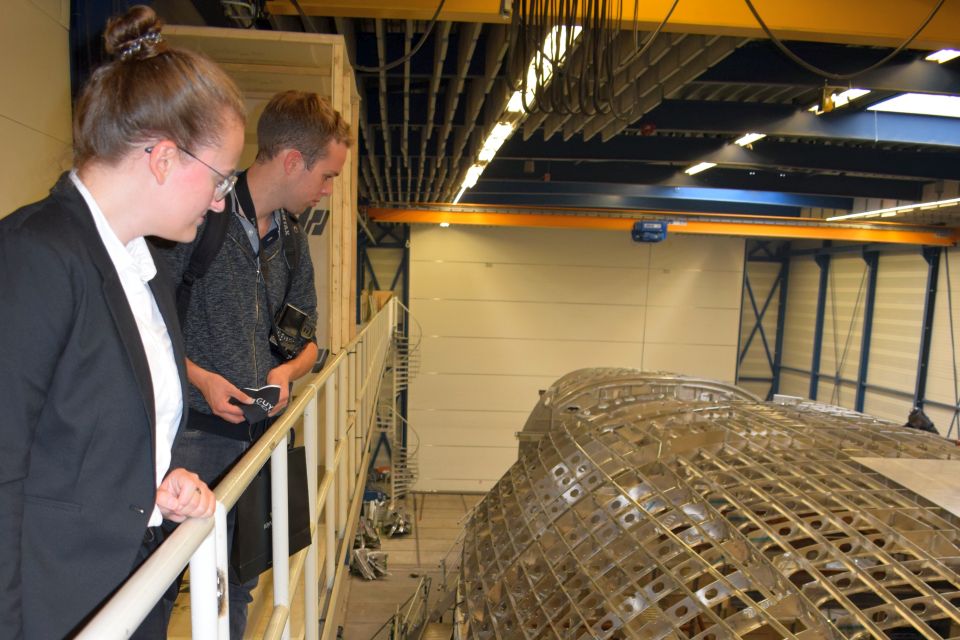

Modern to 1930s

Next, Coronel and Van ‘t Verlaat show the three guests around three yachts under construction. The 58.50-metre motor yacht Phi, “the world’s longest motor yacht under 500 GT”, will be delivered this year. The 46-metre sailing yacht with project name 405 AKA “Reichel/ Pugh/ Nauta 151” has been under construction in alu and carbon since December 2020 and will be delivered in 2022. And then there is the MM597, an almost 60-metre pod-driven sailing yacht with an Alustar hull, which is due for completion in 2022.

Finally, we take a look in a hall, where the two-masted Atlantide from the 1930s is being stripped down completely. Van ‘t Verlaat: ‘Jim Clark, who had three ships built here, recently bought her. She took part in the evacuation of Dunkirk’.

Picture (top): A quick look without a face mask at the upturned hull of Royal Huisman’s Project 405, a 46-metre fast sailing yacht designed by Reichel/Pugh and Nauta Design (photos Sander Klos).

SWZ|Maritime’s superyacht special

Later this week will see the publication of SWZ|Maritime’s September superyacht special. Our special dives into the world of Dutch superyacht building and shows why shows why Dutch yacht builders are among the world’s best. Topics include electrification, an energy label for superyachts, innovative fenders, hydrofoil research and much more.

SWZ|Maritime is available to subscribers only. Not yet a subscriber? Please visit our subscriptions page.

Also read: Royal Huisman turns hull of superyacht Project 404

Profile Guy Fleury

Guy Fleury (21) is a fourth-year student of Maritime Engineering and successfully presented and defended his graduation project on 28 June. After his studies, he will be working as a freelance photographer and wants to work two days a week as a freelance engineer, naval architect or designer.

What fascinates him about the profession: ‘In any case, I would not want anything else than the (super) yacht sector. Within that sector, I find design and naval architecture the most fun and interesting. I am also a photographer and I like the combination of taking photographs and learning how a yacht is put together.’

The most striking thing about Royal Huisman: ‘It is always beautiful when you enter. Here everything is done under one roof, they make little use of external parties. This is very different at the other shipyards I visit.’

What does it take to get you to send an application letter to a (super) yacht yard? ‘Not much, because I would do that anyway. Besides, I never have to send a letter of application, because through my large network and photography I always come across something.’

Profile Amy Spijkerman

Amy Spijkerman (21) has been studying Maritime Technology since 2017. ‘It is a challenging programme where you can use your own imagination in projects. In addition to the “standard” theoretical subjects such as mathematics and statics/dynamics, you get an idea early on in the programme of what you are working towards and what you are learning for. You learn about all the markets in the maritime industry.’

After this programme, she wants to delve deeper into the material she learned at the hbo (higher vocational education). ‘That is why I am doing a pre-master at Delft University of Technology. I also hope that with a future employer, just as we were taught, I can also put some creativity into the work. That is why I want a good combination between contact with the workplace and what you are doing as an engineer. Until now, of course, it has all been fictional and I would like to see how the creative ideas of the engineering department are really applied on the work floor.’

‘During my studies I developed a fascination for the subject dynamics/statics/FEM, etc. Here you go deeper into the forces and possible moments that may occur during sailing. You also try to come up with the best possible construction to make the ship light and strong. That’s how I found out what kind of strange construction styles you can use to create high resistance. That appeals to your creativity: how do you make a pillar lighter while retaining its strength?’

What she found most striking at Royal Huisman was how the yard tries to motivate clients to think about the environment, ‘even if it’s only the small systems or different applications of materials. In addition, their production method is still progressive; they think carefully about the planning and as a result get into less trouble along the way.’

She prefers to send a job application to a company that thinks progressively about the environment or other techniques. ‘That is very important to me.’

Profile Harmen Terlouw

Before joining NHL Stenden University as a lecturer/researcher in 2016, Harmen Terlouw worked at the Shipping Inspectorate and the Ministry of Health, Welfare and Sport Department of National Vessels, Shipyard De Amstel in Ouderkerk aan de Amstel as a planning engineer/acting manager, Shipyard Haak in Zaandam as planning engineer/acting manager, Shipyard Barkmeijer in Stroobos as project leader, Conoship International in Groningen as designer, Volharding Shipyards in Westerbroek as designer and at Groot Ship Design in Leek as designer.

Studying Maritime Technology in the Netherlands

Maritime Technology (formerly Shipbuilding) at the higher vocational education (hbo) bachelor level is offered in the Netherlands in Rotterdam (STC) and in Leeuwarden (NHL Stenden Hogeschool). The structure of the study in Leeuwarden can be found on the college’s website.

The study does not have any graduation tracks. Specialisation takes place through the student’s choice of internships, a minor and the graduation subject. One condition is that the student is involved in maritime technology and that the company or institution can supervise the student to a sufficient level.

In Leeuwarden, Maritime Technology is also offered as a two-year Associate Degree programme. This is a dual variant, which means that people work and study simultaneously, whereby part of the assignments can be done in their daily work. In Sneek, Maritime Technology is offered as an mbo4 course (post-secondary vocational education). From this course, people move on to Maritime Engineering hbo courses.

Maritime education in mainly the north of the country can be found on the Maritime Academy Holland website. An overview of the international levels can be found on Wikipedia.

Credits (European Credits, 1 EC stands for 28 hours of study) for the minor can also be obtained at other colleges of applied sciences and universities in the Netherlands and Europe, as there is agreement on the value/content of an EC. The examination committee will decide whether the minor can be taken. The student must make clear what the minor contributes to his/her education in maritime engineering.