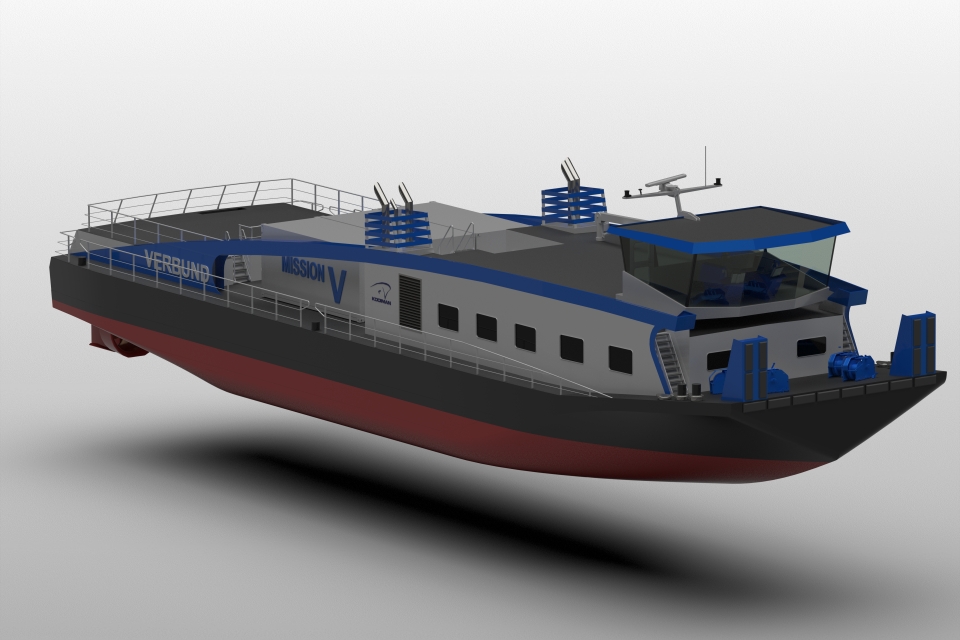

Kooiman Marine Group has received an order from Verbund Hydro Power GmbH for a new pusher tug. The vessel will transport split hopper barges and can function as an icebreaker on the River Danube in Austria. It can also easily be converted to operate on hydrogen.

Prior to securing the order, Kooiman Engineering, a division of the Kooiman Marine Group, developed a concept design in close collaboration with Verbund Hydro Power. Verbund is a leading electricity supplier in Austria and operates ten hydropower plants on the River Danube.

The company requires a pusher tug to handle a pair of split hopper barges that are used for the maintenance of the gravel bed around the dams. The vessel should be powerful enough to push the combination upstream.

Also read: VIDEO: How Kooiman lengthened dredger Swalinge

High pushing force in very shallow water

Jiri de Vos, lead engineer at Kooiman, shares insights into the process: ‘At first, Verbund did a market inquiry with a concept design. It quickly became obvious that the vessel would need to develop a very high pushing force in very shallow water. Due to our experience designing and building four powerful pusher tugs for Veerhaven and the very manoeuvrable workboats Zwerver 2 and 3, we were able to propose a suitable design.’

Beyond its primary role, the pusher tug will also be used to break ice, preventing the accumulation of drifting ice against the dams. As a producer of green energy, Verbund is strongly engaged in the production and the application of hydrogen, as a means to reduce emissions of greenhouse gases and nitrogen oxides. The pusher tug will be prepared to enable an easy conversion to hydrogen for propulsion in the future.

‘It certainly won’t be an off-the-shelf ship,’ adds De Vos. ‘There is quite a bit of ground to cover before we can go on sea trials. Kooiman Engineering will first detail the design. After that, we can do most of the work in-house, such as the ship’s interior, piping, machining of the propeller shafts and the outfitting at one of our three shipyards. We also bring a number of reliable suppliers on board, so we can achieve an outstanding finished product.’

Also read: Van Oord orders another two water injection dredgers with Kooiman