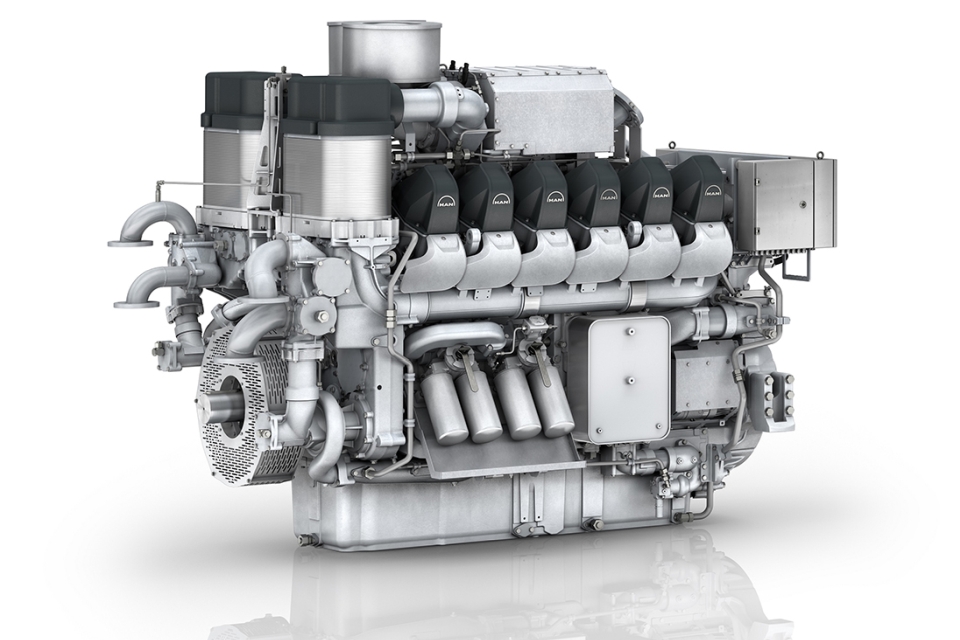

MAN Energy Solutions will make a dual-fuel version of its MAN 175D high-speed engine, capable of operating on methanol, available by the end of 2026. The new variant, designated MAN 175DF-M, will be available both as newbuild and retrofit variants.

According to MAN Energy Solutions, the 175DF-M will be optimised for diesel-mechanical and diesel-electric propulsion to achieve the largest methanol share and best efficiency for various applications and load profiles. In fact, the engine has already been awarded the “fuel ready” certificate by DNV, guaranteeing the introduction of this dual-fuel methanol technology.

Also read: MAN solution aims for 70% reduction in methane slip

Latest addition to the high-speed maritime sector

‘The MAN 175D has proven to be very competitive in terms of sustainability and efficiency with the lowest fuel consumption, lowest lube-oil consumption and longest overhaul times in its class, minimising its environmental footprint,’ states Florian Keiler, head of High Speed, MAN Energy Solutions. ‘In terms of future fuels, the next logical step, apart from being able to run on 100 per cent bio-fuels, is to ensure methanol combustion.’

The 175D engine is MAN Energy Solutions’ latest addition to the high-speed maritime sector and is, as such, one of the pillars of its efforts to develop a methanol-ready engine portfolio as the demand for such technology has rapidly been increasing of late.

Also read: Wallenius orders MAN methanol engines for car carriers

Port Fuel Injection technology

With its success in achieving series-approval for its two-stroke engines, MAN Energy Solutions has used this experience to develop an optimised solution for its four-stroke engines, including successful single-cylinder testing. As such, the results of these efforts will fuel the upcoming development and validation of the dual-fuel PFI (Port Fuel Injection) technology for its methanol-ready 175D engine.

Keiler: ‘Based on numerous exchanges with customers, we came to the conclusion that the dual-fuel principle, reliability, efficiency, a high methanol share, competitive life-cycle costs and maximum achievable output were key requirements for the 175DF-M’s development. Therefore, after conscientious investigation and consideration, we settled upon the PFI combustion technology as the most favourable. Fundamental combustion development will start in 2024, leading up to a first field-test of the methanol engine in 2026. The MAN 175DF-M engine will subsequently be ready for sales release at the end of 2026.’

MAN Energy Solutions believes that PFI is the most advanced technology currently available. Its development targets a highest methanol share over a wide power range while achieving the highest cylinder output in its high-speed engine class. In particular, optimisation for diesel-electric multi-engine plants will allow operation of the engines at an optimal load point achieving the highest methanol share.

As a result, when using biofuels, the MAN 175DF-M’s carbon footprint will be reduced to zero while retaining full fuel-flexibility for operation anywhere in the world.

Also read: MAN to investigate marine hydrogen engine concepts