MAN Energy Solutions is developing an oxidation catalyst for four-stroke engines that will significantly reduce methane slip. Called “IMOKAT II” and developed at the company’s headquarters in Augsburg, Germany, the research project is currently undergoing testing at MAN’s Frederikshavn, Denmark facility.

Funded by the German Federal Ministry for Economics and Climate Action, the new project will investigate the operational experience of a pre-turbo methane-oxidation catalyst, ultimately aiming for a seventy per cent reduction of methane emissions at 100 per cent load.

Also read: Wallenius orders MAN methanol engines for car carriers

Technology demonstrator

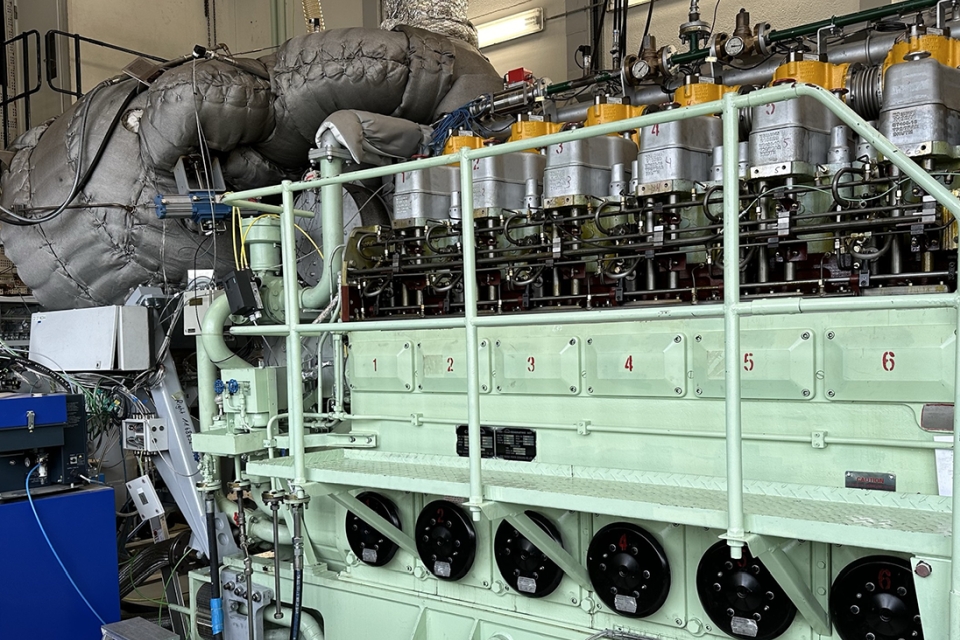

Whereas the predecessor project, IMOKAT I, investigated different catalytic materials and uncovered a sulphur-resistant material without any precious metals that facilitated high methane-conversion, IMOKAT II is a prototype and technology demonstrator.

In this context, it is currently investigating the material’s potential on a test engine with the major goal of designing a catalyst solution that can be applied to a full-scale engine to reduce methane emissions in the field. Field testing aboard a vessel is scheduled for Q1 2024.

‘Part of the project involved studying different approaches to methane reduction,’ states Hans-Philipp Walther, head of Exhaust Gas Aftertreatment at MAN Energy Solutions. ‘Previous attempts to use precious-metal catalysts have resulted in the catalyst elements themselves becoming significantly expensive. Additionally, due to poisoning, you either have to use a lot of such material or install additional technology to protect it. IMOKAT II is therefore not only more robust, but also more economical and requires less installation space. As no commercially-available technology yet exists on the market, the field test will be the first time ever that a vessel sails with a methane catalyst.’

Also read: MAN to investigate marine hydrogen engine concepts

Sulphur-resistant

The catalyst material chosen without precious metals is sulphur-resistant, which is an important design consideration as – even during gas operation – pilot – and lube-oils contain traces of sulphur. It also means that it is possible to preheat the catalyst in diesel mode before switching to gas operation, where a cold catalyst would not be able to perform optimally and methane slip would occur.

MAN Energy Solutions reports that pre-turbocharger integration of the catalyst is necessary because of the exhaust-gas pressure and temperature level there. Integration is much more complex there compared to a post-turbocharger installation, as is found with SCR (Selective Catalytic Reduction).

Walther: ‘The greatest challenge to developing this catalyst is reaching the highest conversion rates since engine and catalyst must be optimised together. Another significant hurdle is optimising the dynamic behaviour of the engine with a catalyst applied, especially if the catalyst is cold. Therefore, a bypass flap and additional software functions will be necessary. However, as part of MAN Energy Solutions’ decarbonisation strategy, we are confident we will overcome these challenges and that the catalyst will become available for retrofit and newbuild applications in due course.’

Picture: IMOKAT II test (by MAN Energy Solutions).

Also read: MAN completes first ammonia engine test