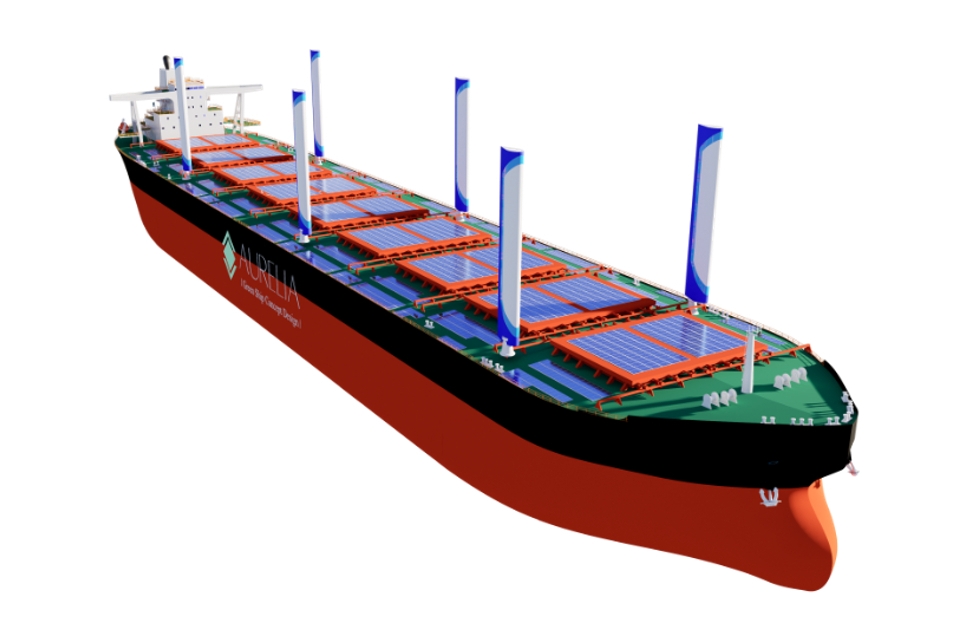

RINA has awarded an Approval in Principle (AiP) for a green retrofit package solution designed by Dutch naval architecture firm Aurelia, Econowind, Wattlab and Vertom. The solution incorporates rigid sails, solar panels, batteries, optimised weather-routing, and a smart decision support system.

Aurelia’s retrofit package solution can be applied to almost any kind of vessel, whatever their purpose or cargo. It does not interfere with operational aspects, such as loading and offloading cargo. Using these solutions, the retrofit design meets CO2 reduction targets in compliance with the Carbon Intensity Indicator (CII) and speeds the path to decarbonisation.

Working with sails experts, Econowind, and leaders in PV technology, Wattlab, Aurelia has shown that big steps towards decarbonisation can be achieved today with practical, viable solutions for the marine industry. Hydrographic and Marine Consultants (HMC) developed the a smart decision support system.

Also read: RINA approves Aurelia’s 100% hydrogen powered RoRo design

Getting a bulk carrier to comply with EEXI and CII

For the Newcastlemax bulk carrier, the challenge was to meet Energy Efficiency eXisting ship Index (EEXI) and the CII index for the reduction of CO2 emissions. The 203,000 DWT bulk carrier in question has a length of 300 metres, a beam of 50 metres and a range of 24,500 nautical miles.

Naval architecture firm Aurelia has developed a CII calculator used to assess the status of the vessel and give an overview of what was needed to comply with the CII index based on five annual sailings between Brazil and China.

Also read: How to get an existing bulk carrier to meet EEXI and CII

Two investment steps

The resulting solution proposes two investment steps for shipowners looking to comply with the CII index. The first, to be done in 2023, involves the installation of Solar Flatrack technology, batteries, and the SafePlan software developed by HMC. The combination of such technologies will aim to reduce the hours in service of the auxiliary engines.

Any surplus energy not consumed by the vessel is used to charge the battery bank. This first stage of the retrofit of the auxiliary engine, reduces the total CO2 emissions by 6.1 per cent, or 3305 tonnes, and marine gas oil (MGO) fuel of the auxiliary engine by 97.5 per cent.

The second stage of investment, required by 2025, includes the installation of six rigid, 30-metre-high sails to provide supporting wind propulsion, along with switching from fossil to biofuels. The added wind propulsion provides power to the vessel and lowers the load of the main engine (2T), thereby reducing fuel consumption and was shown to reach 1237 kW at 67 per cent operation per day.

With the use of biofuels to further lower emissions, this investment stage reduces CO2 emissions by 10.3 per cent or 5560 tonnes of CO2 per year.

Applying the retrofit solution to a general cargo vessel

The standard dimensions and mounting method of a 20ft container and the minimum height make the model applicable to not only bulk carriers but also general cargo.

Shipping company Vertom joined the retrofit project with the general cargo vessel MV Anna. Since 2022, Vertom has already started the retrofit process for efficiency improvements and carbon reduction of MV Anna by installing two 16-metre Econowind VentoFoils on the bow.

For a more powerful and complete retrofit, Solar Flatrack are being tested this year and will be added to existing Vertom vessels in 2023, showing that this combined solution is possible not only for bulk carriers with available space on decks, but also for general cargo vessels.

The Solar Flatrack is a modular solar energy system, that comprises movable, stackable, thin plates with integrated solar panels and inverters and acts as a sustainable generator.

Picture by Aurelia.

Also read: ONE orders containerised wind-assist units from Econowind