Today (14 March), Van Oord’s second dual-fuel LNG-powered trailing suction hopper dredger Vox Apolonia in a series of three will be christened. SWZ|Maritime was given a sneek preview with a tour of the vessel a day before.

The state-of-the-art Vox Apolonia and its two sister vessels, Vox Ariane and Vox Alexia, boost the mid-class section of Van Oord’s fleet of trailing suction hopper dredgers. These three new LNG vessels have a significantly lower carbon footprint than conventional trailing suction hopper dredgers and fit in with Van Oord’s aim of making its fleet more economical and sustainable. It is precisely for this reason that the three vessels won the Dutch KVNR Shipping Award in November 2022.

The Vox Apolonia was built at the Keppel Singmarine Pte Ltd shipyard in Singapore and delivered to Van Oord in December. The vessel then travelled to the Netherlands for dredging trials. On 14 March, the vessel will be christened in Rotterdam.

The Vox Ariane was christened back in June 2022 and has already been successfully deployed on several projects. Triplet sister vessel Vox Alexia is still under construction in Singapore and is expected to join the fleet at the end of this year.

Also read: Van Oord takes delivery of LNG-powered dredger Vox Apolonia

LNG

The three ships will sail under the Dutch flag and are the latest additions to the fleet powered by the transition fuel LNG. Operating on LNG results in low emissions, but when operating on marine gas oil (MGO), the ships also comply with IMO Tier III. Moreover, there is innovative use of dual-fuel engines; both engines can independently run on both BOG (boil-off gas) and liquid LNG or MGO in any combination.

According to captain Theo Haegens, the Vox Apolonia can carry enough LNG to operate on for about two weeks.

Van Oord sees LNG as a transition fuel. When asked, Marjolein Boer, director of communications at Van Oord, says the vessels have not been designed with a future switch to another fuel in mind. ‘These are really meant to operate on LNG during their lifespan, which is typically between twenty and thirty years. We do not have a retrofit in mind.’ However, should new technologies become available to reduce emissions further, of course Boer does not rule out these to be incorporated on the dredgers.

Automation and simulator

The trailing suction hopper dredgers are innovative and modern vessels of own design. Savings have been made on weight and ship design has been optimised. Automation is smarter and remote monitoring can be improved. Smart energy efficiency has been achieved with regard to the use of residual cold and waste heat for the on-board climate control system.

The vessel is usually operated by a crew of fifteen, says captain Haegens. ‘In theory, the vessel can be operated from the bridge by just a single crew member, if regulations were to allow it.’

In addition, Haegens says Van Oord has had a simulator built, which is a copy of the systems of the sister dredgers. This allows new crew members to practice on shore and familiarise themselves with the vessels and their systems before coming on board.

Climate adaptation

Van Oord envisages two major drivers for the future: the rapidly increasing demand for climate adaptation solutions and offshore energy projects. The Vox Apolonia and its sisters fit in with the first category.

‘The dredgers are ideally suited to climate adaptation projects,’ says dredging director Mark Roelofs. ‘The vessels were built to be wider, which is more expensive, but also this reduces their draught. It allows them to get closer to shore and to take more sand in one go. As a result, projects can be executed faster, reducing inconvenience to the surrounding area.’

Also read: Van Oord back in the black in 2022

Dredging

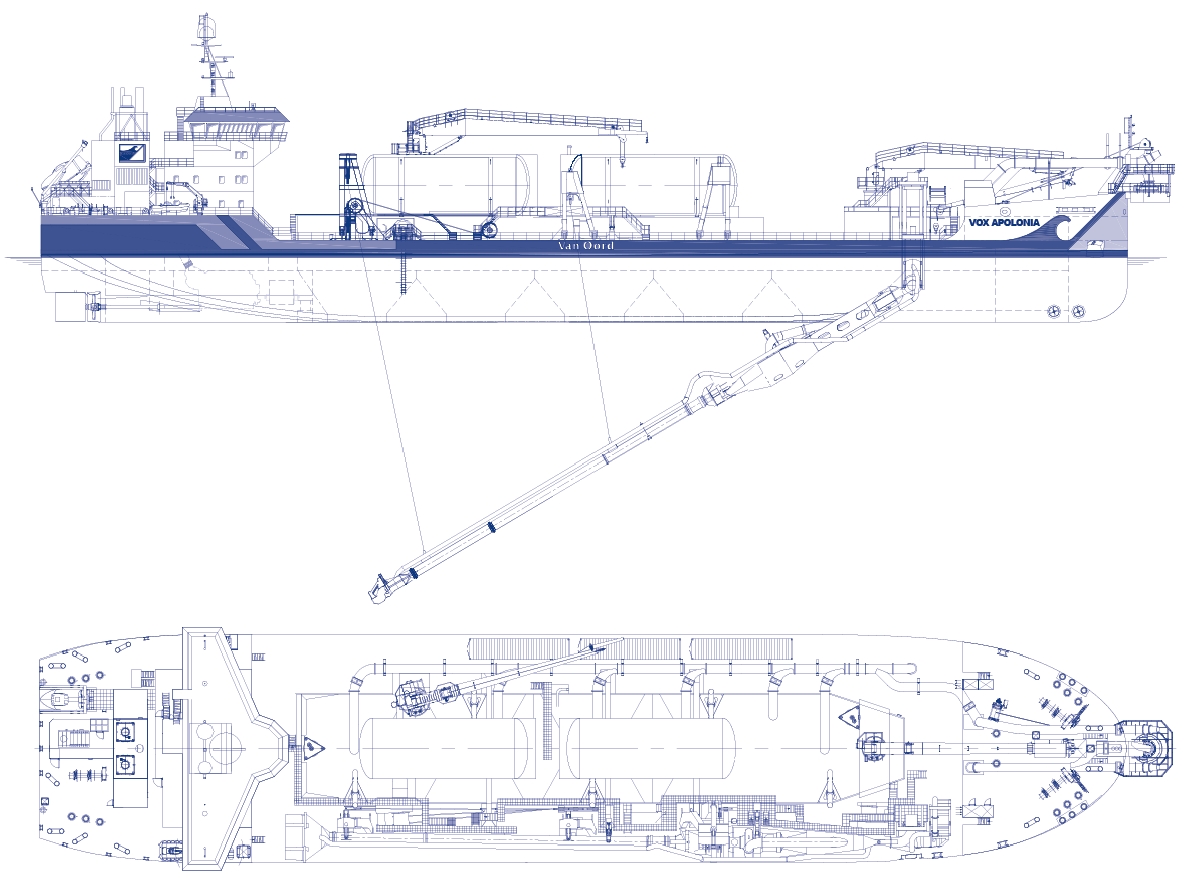

The vessel has a hopper volume of 10,700 m3. The Bureau Veritas classed trailing suction hopper dredger has one suction pipe with a submerged e-driven dredge pump, two shore discharge dredge pumps and five bottom doors.

‘Emptying the vessel using the bottom doors, takes about five minutes,’ says Haegens. ‘Rainbowing takes between thirty to forty minutes.’

Details of the Vox Apolonia

- Length overall: 137.50 m

- Breadth moulded: 27.60 m

- Moulded depth: 9.80 m

- Draught – dredging mark I – 15 miles: 6.80 m

- Draught – dredging mark II – 8 miles: 7.80 m

- Hopper capacity: 10,700 m3

- Deadweight (int.): 15,600 tonnes

- Max. dredging depth: 55 m

- Suction pipes: 1 x dia. 1,10 m

- Speed empty: 15.1 knots

- Speed loaded @ 7.8 m draught: 12.3 knots

- Propulsion: 2 x 4000 kW

- Bow thrusters: 2 x 500 kW

- Total power installed: 14,410 kW

- Inboard dredge pumps: 2 x 2700 kW

- Submerged dredge pumps: 1 x 2600 kW