MAN has won the first order for its G80 dual-fuel methanol engine. The engines will be placed in nine new 9000 TEU container ships for HMM.

Hyundai Samho Heavy Industries Co. and HJ Shipbuilding & Construction Co. (HJSC) have respectively ordered seven and two MAN B&W G80ME-LGIM dual-fuel engines. The newbuildings will be delivered to HMM from 2025 and will operate on routes to North and South America as well as India.

The engines, which are capable of operation on green methanol and conventional fuel-oil, represent the first order for the G80 bore size. They will also feature MAN Energy Solutions’ proprietary EGR (Exhaust Gas Recirculation) systems. The G80 engines will, upon delivery, be connectivity-ready and prepared for digital services such as PrimeServ Assist.

‘This world-first order for a G80 methanol engine is just a continuation of the general market trend toward methanol where the ME-LGIM engine has become the de facto industry standard for large, methanol-fuelled, merchant marine vessels,’ says Bjarne Foldager, senior vice president and head of low-speed, MAN Energy Solutions. ‘At MAN Energy Solutions, we expect further projects for this size of container vessel to be specified with our G80 methanol engine within the near future. As such, methanol is quickly becoming the most prominent alternative fuel in the container vessel segment.’

Also read: MAN mixed-engine concept to power Cadeler’s new jack-ups

100 methanol engines

MAN now has more than 100 ME-LGIM engines on order or in service.

Thomas S. Hansen, head of promotion and customer support at MAN Energy Solutions: ‘In our open project pipeline, container vessels make up around 61 per cent, followed by both tankers and bulk carriers with seventeen per cent, and general cargo making up the remaining five per cent. MAN Energy Solutions’ methanol engines are a proven concept that combine well with methanol’s unique selling points as a fuel that include its easy storage, simple auxiliary systems, and not to forget that green methanol is entirely carbon-neutral.’

Also read: VIDEO: First ship completes net-zero trans-Atlantic voyage on bio-methanol

Increasing methanol production

Along with the new order, HMM has also signed MoUs with multiple fuel suppliers to ensure the methanol supply for the vessels. In this regard, according to the Methanol Institute (MI), more than eighty renewable methanol projects globally are projected to produce more than 8 million metric tonnes of e-methanol and bio-methanol annually by 2027.

Renewable methanol is a low carbon and net carbon-neutral liquid chemical and fuel produced from sustainable biomass, often called bio-methanol, or from captured carbon dioxide and hydrogen produced from renewable electricity, referred to as e-methanol.

In addition to the growing number of projects, MI reports clear evidence that bio-methanol and e-methanol facilities are ramping up production. With ongoing advancements in technology and increased government support, it expects the capacity of individual renewable plants to rise from 5-10,000 metric tonnes of methanol to 50-250,000 metric tonnes or more annually over the next five years.

Also read: HMM orders nine methanol-fuelled container ships

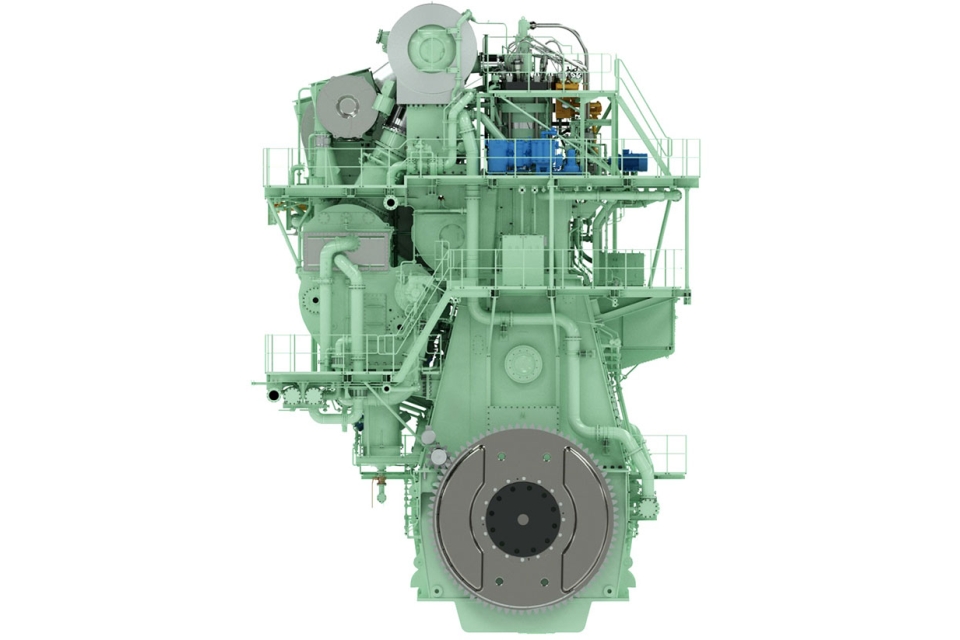

About the ME-LGIM engine

MAN Energy Solutions developed the ME-LGIM dual-fuel engine for operation on methanol, as well as conventional fuel. The engine is based on the company’s proven ME-series and works according to the Diesel principle. When operating on green methanol, the engine offers carbon-neutral propulsion for large merchant-marine vessels.

MAN Energy Solutions developed the ME-LGI engine in response to interest from the shipping world in operating on alternatives to fuel oil in order to reach decarbonisation targets. Methanol carriers have already operated at sea for many years using the engine, and, as such, the ME-LGIM has a proven track record offering great reliability and high fuel-efficiency.