Damen Marine Components has received the order to design, engineer and produce eight rudders for the four F126 frigates that Damen Naval is building for the German navy. Each vessel will be equipped with two rudders, developed to withstand extreme shocks and to improve the hydrodynamic properties of the fast vessels.

The full spade rudders of the Atlantic type by Damen Marine Components (DMC) are purpose-designed for the frigate project to fit the specific hull form and operational profile of these naval vessels. The rudders have a relatively slim profile to reduce drag and improve course keeping at high speeds, maintaining good manoeuvrability at low speeds in harbours or during special operations.

Also read: Damen Marine Components wins first multi-vessel order in the US

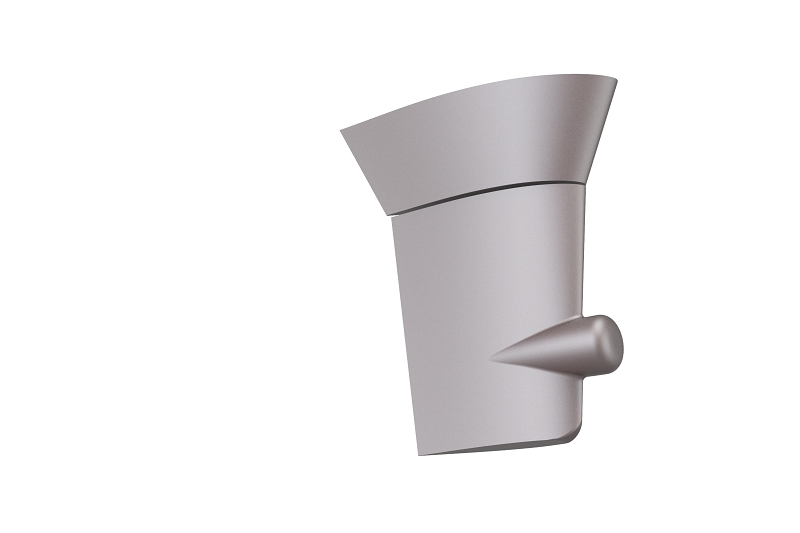

Asymmetric Rudder Technology and Silent Bulb

The unique Asymmetric Rudder Technology (ART) as developed by DMC will be applied. This means that the leading edge of the rudders will be asymmetric, directing the turbulent water flow from the propellers in front of the rudders along the rudder surface more smoothly. This reduces cavitation, increases rudder efficiency, and reduces drag of the vessel.

Further improvement of efficiency is acquired by the Silent Bulb that is incorporated in the rudders, right in the wake of the propeller axis. This is an energy saving addition to the rudder profile, positioned on the centre line of the propeller. The Silent Bulb improves the water flow that comes from the propeller and increases thrust at higher loads. The design of the bulb is significantly influenced by the distance to the propeller, and it is shaped to fit perfectly with the propeller hub.

Also read: Atlas supplies anti-submarine warfare technology for German F126 frigate

Specific to F126 hull

Based on the principles of improved water flow, drag reduction and fuel saving, DMC designed the rudders with all of these specific qualities specific to the F126 hull. The rudder profile was investigated intensively, tank tests have been performed to obtain the optimum shape with regards to resistance reduction and manoeuvring improvement.

As the F126 vessels are equipped with twin counter rotating propellers, the rudders for any vessel are designed to direct the water flows in the wake of propellers moving opposite to each other.

Shock resistant specifications

Special requirement for the naval operations of the F126 is to build the whole vessel, including the rudders, to extreme shock resistant specifications. The rudders are designed to withstand enormous shock loads. Based on extensive computational calculations, critical areas are strengthened and special welding details are applied. High strength steel of the best quality is used for construction, honouring the classification rules for naval ships.

Also read: Damen’s German F126 frigate contract will not be extended

F126 contract

The F126 frigates are one of the largest procurement projects in the history of the German navy. On 19 June 2020, the German Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) and Damen Schelde Naval Shipbuilding signed the contract for the construction of the F126.

The frigates will be built at shipyards in Kiel and Wolgast, while the final outfitting and commissioning will take place in Hamburg at Blohm+Voss. The contract also includes logistics services and multiple land-based test and training sites. Delivery of the vessels is scheduled from 2028 until 2031.