Huisman has reached an important milestone in the development of a new jacking system, tailored for the growing offshore renewables energy market. The company has completed a Factory Acceptance Test for the first Huisman Jacking Gearbox, which will be part of the jacking system.

The Huisman Jacking System, available in a range of models, is specifically designed for wind turbine installation jack-up vessels, taking into account the requirements of today and tomorrow. The system contains a dedicated proprietary control system, which optimises the system’s load distribution, specifically for turbine and foundation installation.

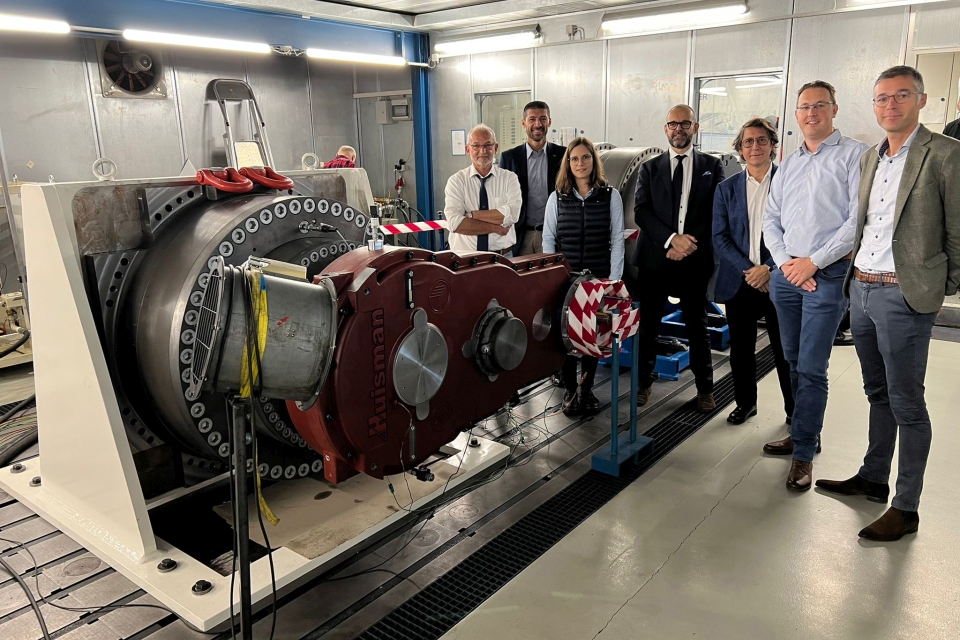

Huisman has teamed up with its long-term supplier of gearboxes for offshore equipment, German based O&K Antriebstechnik, part of the Bonfiglioli Group. An important aspect of a successful delivery of the gearbox has been the Factory Acceptance Test (FAT), consisting of multiple tests under motion at O&K’s test facility in Hattingen. Upon delivery of the gearboxes to one of its production facilities, Huisman will continue with full-load jacking demonstration trials.

Also read: How Huisman’s new composite casings will help turn CO2 into stone

Huisman enters jacking market

Huisman has extensive experience in the application of large-scale drive systems in offshore applications that include large pinions, large gearboxes, and large amounts of power, combined with sophisticated control systems. With the new jacking system, the company will apply its experience to the jacking market.

‘We are proud of achieving this important milestone for our new range of jacking systems,’ says Cees van Veluw, Product Manager Cranes at Huisman. ‘This will further enable the implementation of the systems in vessel designs that may emerge in the years to come. The interest of vessel owners, operators and designers has encouraged us to apply our knowledge and expertise to this.’

Also read: Heerema orders Motion Compensated Pile Gripper from Huisman

Features of the Huisman Jacking System

- Two gear versions available – L and XL version – suitable for vessel designs of various independent design companies, thus allowing owners to freely select the vessel’s hardware of preference.

- Static pinion loads up to 800 tonnes (L) or 1000 tonnes (XL).

- Flexible suspension method for smart integration with the vessel design.

- Potential to achieve leg preload capacities beyond 30,000 tonnes, depending on leg layout and the system’s number of layers.

- Advanced and efficient control by Huisman’s proprietary Variable Frequency Drive Control System.

- Easy integration of power system with cranes from various brands, and power grids from various electrical integration companies.

Picture (from left to right): Jürgen Jescheniak, R&D Manager O&K Antriebstechnik; Fabio Campana, Product Marketing Manager at Bonfiglioli; Grit Nachtigäller, Project Engineer at O&K Antriebstechnik; Marco Cesari, General Manager BU Mobile and Wind Solutions at Bonfiglioli; Stefano Callegati, Managing Director at O&K Antriebstechnik; Cees van Veluw, Product Manager at Huisman; and Henk Weterings, CTO at Huisman.

Also read: Huisman presents semi-sub drilling rig design to bridge gap to renewables