Carbfix has contracted Huisman for the delivery and installation of Huisman Composite Tubulars. The pipe system will be installed in the pilot well of the Coda Terminal, a large carbon transport and storage hub in Iceland. The company has developed a process that turns CO2 into stone.

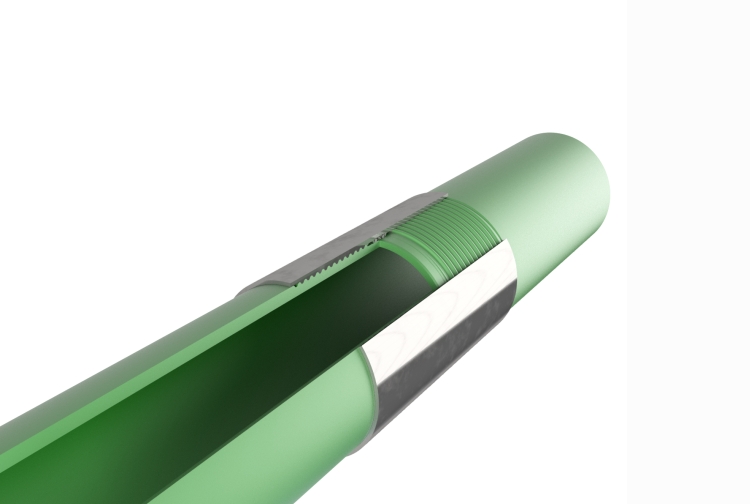

In-house, Huisman has developed a fit-for-purpose downhole composite pipe system, specifically for well construction purposes, to provide a smooth, full flush, flow path for production and injection of fluids. By shifting from conventional steel to composite materials, Huisman Composite Tubulars tackle corrosion problems at the core and reduce scaling tendency to a minimum, providing a durable and efficient solution.

After installation and cementation of the 9 5/8” composite casing, an 8½” open hole section will be drilled to the target depth. This means that the bit and drill pipe will be run through the inside of the composite casing, a unique procedure made possible by the strong, fully composite pipe body.

Also read: Heerema orders Motion Compensated Pile Gripper from Huisman

CO2 into stone

Carbfix, based in Kópavogur, Iceland, has developed a process that turns CO2 into stone. CO2 is dissolved in seawater before it is pumped into a basaltic bedrock formation through a network of injections wells. Once in the subsurface, the injected CO2 reacts with the rock, forming stable carbonate minerals, thus providing for safe, long-term storage. A process which takes about two years.

The Coda Terminal pilot well will be located near Straumsvík. At full scale, the terminal will have the capacity to inject 3 million tonnes of CO2 per year for permanent mineral storage.

‘We are grateful for this order and excited to support Carbfix in their development of this new green tech industry,’ says David Roodenburg, CEO of Huisman. ‘This carbon storage application provides a perfect example of the beneficial capabilities of Huisman Composite Tubulars. We look forward to a successful pilot and further roll out of the Coda Terminal.’

This year, Huisman received a contribution from the National Growth Fund of the Dutch Government for further expansion of Huisman Composite Tubulars.

Also read: Huisman presents semi-sub drilling rig design to bridge gap to renewables

Features & benefits of Huisman Composite Tubulars

- Huisman Composite Tubulars are naturally inert to downhole corrosion.

- Maximum production is maintained by the smooth low friction surface, further mitigating scale build up and reducing losses.

- The Composite Tubulars proprietary slender connections assure maximum internal diameter availability, providing unrivalled pump efficiency.

- Designed and tested to last for up to thirty years in downhole applications.

- Made of viscously strong and robust non-metallic material that’s ready for conventional equipment and procedures.

- Eighty per cent lighter than steel, enabling safer and rigless running operations.

- Transparent for electromagnetic logging.

Also read: Huisman to supply Leg Encircling Crane to Cadeler’s F-class vessel