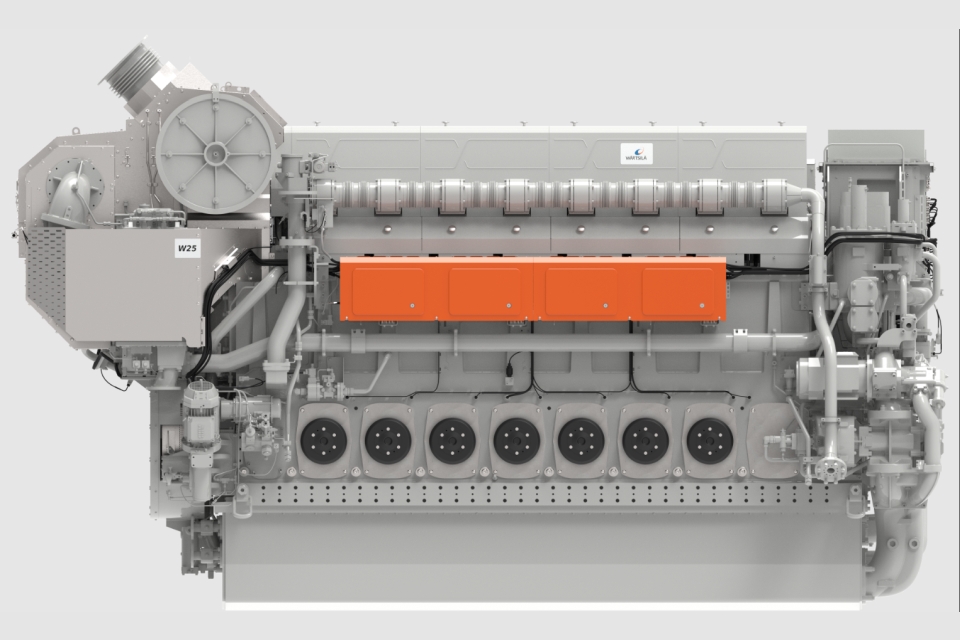

Wärtsilä has introduced its new Wärtsilä 25 medium-speed 4-stroke engine. The engine can operate on diesel, LNG, or on either gas or liquid carbon-neutral biofuels, and can easily be upgraded to operate with future carbon-free fuels as they become available.

The 25 engine’s modularity offers shipowners and operators maximised flexibility, while the engine’s efficiency and fuel economy deliver minimised emissions. The flexibility of having different valve timing options is a key enabler for future fuels and emissions optimisation.

Also read: Wärtsilä and Maersk to develop ‘pipe in pipe’ solution to prevent scrubber discharge pipe corrosion

First Wärtsilä engine to run on ammonia

The 25 is intended to be the first Wärtsilä engine to run on ammonia as a fuel – technology development is currently underway with a technology concept readiness slated for 2023, followed by planned product release soon thereafter.

‘This engine marks the beginning of a new era of future-proof medium speed, small-bore engines, and comes as an important step towards the maritime industry meeting its decarbonisation goals,’ says Roger Holm, President Marine Power & Executive Vice President Wärtsilä Corporation. ‘The Wärtsilä 25 ticks all the boxes. It is a small, but powerful engine, and it provides an effortless transition to future fuels, making it a future-proof investment already today. Most importantly, the Wärtsilä 25 brings all of these advantages whilst keeping the total cost of ownership within reason.’

When operating with natural gas, the engine is IMO Tier III compliant, as it also is with diesel when integrated with a Wärtsilä NOx Reducer (NOR) emissions abatement system. Furthermore, it enables economically viable compliance with regulations, such as the IMO’s CII and EEXI protocols that enter into force in 2023.

Also read: Wärtsilä completes Russian market exit and centralises engine manufacturing in Finland

Reduced downtime and operating costs

The Wärtsilä 25 is designed for long periods of maintenance-free operation and it supports dry-docking schedules with a time-between-overhauls (TBO) of up to 32,000 hours. As a result, both downtime and operating costs are significantly reduced. Data-driven dynamic maintenance planning and predictive maintenance services can extend the TBO even further.

The Wärtsilä 25 features a robust and highly efficient turbocharging system with a high pressure ratio. It is now available in 6L, 7L, 8L and 9L cylinder configurations, while the dual-fuel (DF) version has a power output ranging from 1.9 to 3.1 MW, and the diesel version from 2.0 to 3.4 MW. The common-rail high pressure fuel injection technology optimises combustion and the fuel-injection settings at all loads. This in turn promotes smoke-free operation.

Predictive maintenance

Other features include a self-learning proportional, integral, derivative (PID) control to reduce calibration needs, and the gathering of critical engine data for predictive maintenance, reporting and analysis purposes via Wärtsilä’s Expert Insight service. The modules can be replaced ‘on the fly’, which eliminates the need for separate software downloads. Optional and easy-to-apply adjustments for arctic or tropical conditions and for reducing emissions to the level of a pure gas engine are also available.

Also read: Wärtsilä coordinates EU funded project to accelerate ammonia engine development