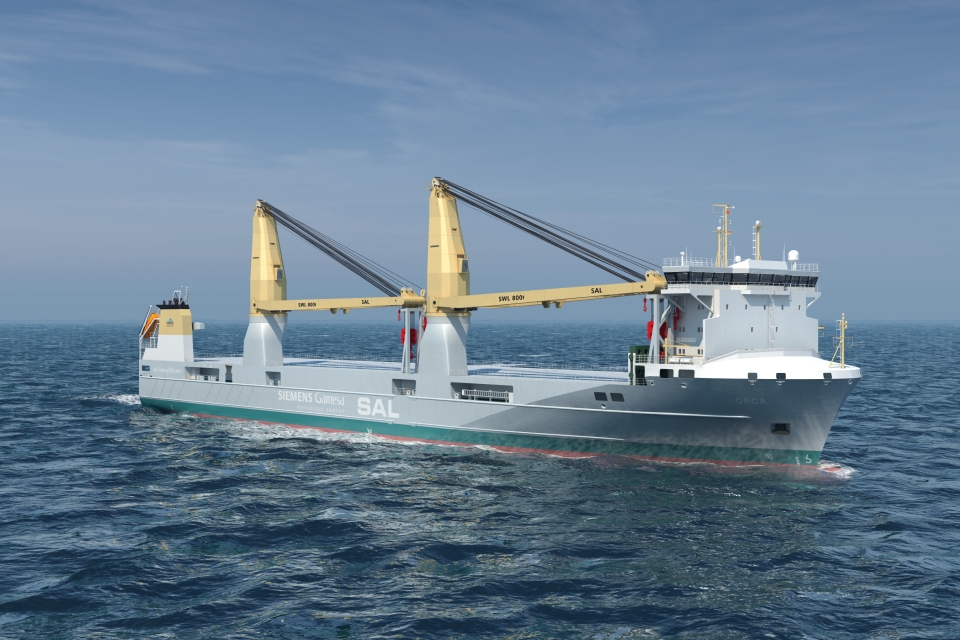

SAL Heavy Lift has signed building contracts for four firm plus two optional new generation heavy-lift ships with Wuhu Shipyard, China. This joint newbuilding programme involving SAL Heavy Lift and partner Jumbo Shipping is called Orca Class. The vessels will be powered by dual-fuel engines that can run on methanol.

The Orca vessels ‘represent the new benchmark both in terms of their technical capabilities and modern climate-friendly propulsion systems,’ says Dr. Martin Harren, owner and CEO of SAL Heavy Lift and the Harren Group. ‘The ships will be the most efficient vessels in their class with consumption and emission figures far superior to any existing heavy-lift vessel today. As a signatory to the “Call to Action for Shipping Decarbonization”, our Group has committed to the decarbonisation of shipping activities by 2050. I am proud that this newbuilding order shows how we are keeping our promise for significant, concrete action.’

The vessels were developed in close cooperation with SAL’s joint venture partner, Jumbo Shipping (Schiedam, the Netherlands). Jumbo Shipping owner Michael Kahn stresses: ‘One can say that these ships mark the beginning of a new era for the Jumbo-SAL-Alliance – no exaggeration. I would like to take this opportunity to thank the newbuilding design team at SAL for their great cooperation. I am very impressed with their passion and technical expertise. The ships will help bring us even closer together.’

Siemens Gamesa Renewable Energy is also involved in the project and will work with SAL on the two first Orcas. According to Thomas Mortensen, Head of Transport Project Execution, Offshore at Siemens Gamesa Renewable Energy, the ‘Orcas meet several of our anticipated medium- to long-term transportation challenges’ among which the increasing size and weight of the turbine components.

Also read: Wout Janssens succeeds Michael Kahn as CEO of heavy lift shipping company Jumbo

Orca class

The vessels measure 149.9 m x 27.2 m and provide a capacity of 14,600 DWT. Despite their compact outer dimensions, the vessels have a box-shaped single cargo hold with the largest dimensions in its class. Provided the hatch covers with a capacity of 10 t/m2 are not utilised for stowing super-heavy deck cargoes, such as 3000-t cable carousels, the vessels can accommodate over-height cargo in the hold and sail with open hatch covers up to full scantling draught.

Ice class notation 1A, a Polar Code certification and the reduced design temperature of the hull and equipment allow the ships to safely operate in cold conditions as well.

Specially designed Liebherr cranes

Two 800-t Liebherr cranes specifically designed for this ship type can handle cargo items weighting up to 1600 t in tandem.

‘Despite extremely high crane pedestals of more than 11 m, the overall crane height and thereby the vessel’s air draught remains at just about 38 m. This makes it possible for the vessel to pass the Kiel Canal and enter strategically important ports worldwide,’ explains Sebastian Westphal, CTO at SAL Heavy Lift. ‘The fully electric cranes are perfect for the vessel’s intelligent energy management and recovery system. This is based on a battery storage system that can be used together with conventional gensets in hybrid mode, or in combination with the vessel’s shore power connection for fully electric port operations.’

Also read: [VIDEO] How Jumbo-SAL shipped three assembled cranes in one go

Optimised hull form

Developed in house, the ship type design expertly combines the experience and know-how from decades of complex heavy-lift project execution with the latest technologies.

Jakob Christiansen, Head of Research & Development, Retrofit & Newbuilding at SAL Heavy Lift, comments: ‘We developed and optimised various vessel details, especially in relation to the hull form and propulsion system, in close cooperation with the renowned Naval Architecture faculty at the Hamburg University of Technology. Recent tank performance tests revealed that we have created one of the world’s most efficient hull forms for a vessel of this size – outmatching all existing heavy-lift and MPP vessels.’

Dual-fuel engines ready for green methanol

In addition to the optimised hull design, the Orca vessels will have an innovative propulsion system consisting of compact and efficient main engines and a diesel-electric booster function. Compared to other heavy-lift vessel designs, this hybrid setup features the widest available range of economic speed settings and redundancy.

At a service speed of 15 kn, the vessels will consume significantly less than 20 t of fuel oil per day – similar to far smaller-sized and geared MPP vessels. Alternatively, the vessels will be able to trade at a slow, ultra-efficient speed of 10 kn at 6 t while still being able to reach a maximum speed of 18.5 kn for urgent deliveries – if a windfarm installation vessel is waiting for an urgent component delivery, for example.

The vessels are equipped with dual-fuel engines, which means that they can use methanol as an alternative fuel. If green methanol becomes available in key ports as anticipated towards the end of the decade, the Jumbo-SAL-Alliance will be able to offer carbon-neutral transport solutions.

Pioneering emission reduction technology

NaMKü (“Sustainable Modernisation of Coastal Vessels”) funding from the German Federal Ministry for Digital and Transport allows SAL to utilise pioneering technology in the vessels innovative power train with the target on highest efficiency and significant emission reduction. Among other eco-friendly effects, this will lower NOx emissions ten per cent below the IMO Tier III level while undercutting EEDI phase 3 limits for CO2 emissions by 21 per cent.

Also read: Jumbo Shipping and SAL Heavy Lift joint venture becomes reality