Annual servicing of a boiler on a drill ship has claimed three lives. The Nautical Institute describes the incident in its latest Mars Report and warns that competent supervision should be the norm as boilers are inherently very dangerous due to high operating temperatures and pressures.

The Nautical Institute gathers reports of maritime accidents and near-misses. It then publishes these so-called Mars Reports (anonymously) to prevent other accidents from happening. A summary of this incident:

A drill ship holding position offshore was due to carry out the annual servicing of its two auxiliary boilers. The boilers were used only for well test operations and had not been operated since the last annual service, except for maintenance operations.

The duty engineers brought the boilers up to temperature and pressure specifications in preparation for the annual checks. As this was underway, the pressure safety valves opened. They appeared to open at 1.9 bar for boiler 1 and 5.9 bar for boiler 2; well below the boilers’ working pressure of 7 bar. Over the course of the next four hours, the boilers were stopped and restarted a further three times. Each time, pressure safety valves operated at what appeared to be too low a pressure.

Two shore based service technicians had now joined the vessel by helicopter but the boilers were not ready for servicing due to the perceived issues with the pressure safety valves. The ship’s engineers, together with the service technicians, again started the boilers to check the operation of the pressure safety valves. They still appeared to be opening below the boilers’ working pressure.

Also read: Junior engineer suffers severe burns in boiler accident

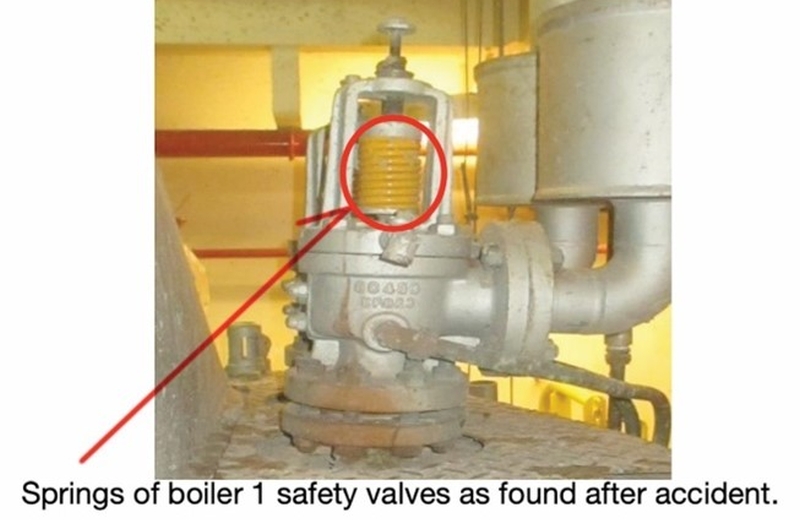

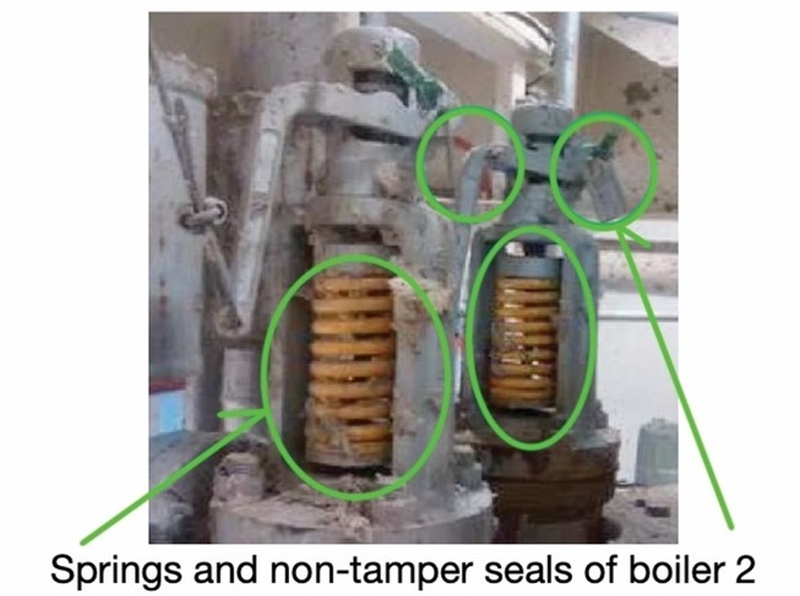

It was decided to shut down the boilers and allow them to cool so the technicians could then overhaul the pressure safety valves. Once cool, the pressure safety valves of boiler 1 were adjusted in situ by the service engineers so they would open at a higher pressure. This explains why the ‘non-tamper’ seals were found missing from the safety valves of boiler 1 after the accident.

The next day, the service technicians resumed the work, together with one of the ship’s engineering personnel. The boilers were started and almost immediately triggered alarms on the machinery monitoring panel. Over the course of the next 36 minutes at least twenty alarms were acknowledged as the team struggled to find the problem.

Then, boiler 1 catastrophically failed from overpressure, filling the boiler compartment with steam. The two service technicians and ship’s second assistant engineer who were in the boiler room suffered lethal injuries. The weathertight door was blown open and the pressure vented to atmosphere, injuring another crewmember who was working nearby.

Investigation findings

The investigation found, among other things, that the pressure sensors of boiler 1 were not operating as required and were giving false pressure readings. Yet the accuracy of the pressure sensors was never questioned as everyone believed they knew the problem; that the safety valves were opening below their set pressure. It is possible that this led to confirmation bias that then set the stage for the unsafe act of adjusting the safety valves to open under higher pressure.

Further, the service technicians’ lack of experience may have contributed to both the confirmation bias and the subsequent unsafe act. Adequate supervision by a qualified professional could have prevented this deviation from established safe practices.

Advice from The Nautical Institute

- In systems that are dependent on several inputs, careful analysis is needed to determine where the real source of the problem lies. In this case, the problem was “upstream” of the safety valves, at the pressure sensors.

- Boilers are inherently very dangerous due to high operating temperatures and pressures. Strict and competent supervision of operation and maintenance should be the norm.

- Safety valve operating parameters should only be set by expert guidance and under test bench conditions, never ‘on the fly’. Once adjusted, the valves are then fitted with a non-tamper seal identifying the set pressure, facility that performed the work and the date of adjustment. These seals should not be removed.

- Be aware of confirmation bias, one of the leading factors in many accidents related to human error.

Also read: Do you conduct a risk assessment before working on your ship’s boiler?

Mars Reports

This accident was covered in the Mars Reports, originally published as Mars 202202, that are part of Report Number 351. A selection of this Report was also published in SWZ|Maritime’s February 2022 issue. The Nautical Institute compiles these reports to help prevent maritime accidents. That is why they are also published on SWZ|Maritime’s website.

More reports are needed to keep the scheme interesting and informative. All reports are read only by the Mars coordinator and are treated in the strictest confidence. To submit a report, please use the Mars report form.