C-Job Naval Architects has chosen a trailing suction hopper dredger as a first autonomous concept design. Submerging such a vessel offers benefits for ship resistance and required vacuum for the dredge pump. To prove these insights, a comparative study was performed between a conventional, manned dredger and the Autonomous Underwater Maintenance Dredger (AUMD).

Another benefit explored during the study is that an increased part of the ship’s volume would generate displacement resulting in additional payload. Moreover, a new arrangement of the vessel could be created resulting in a reduction in overall hull girder loads and reduced steel weight.

Although it is not foreseen that the current concept design will be sailing in the upcoming years, at least not in the current scale, the concept does show the high potential of autonomous shipping, merely if the design fully utilises the full range of design options autonomous shipping offers. In the longer term, C-Job aims to develop autonomous vessels fully from scratch, which should lead to most efficient and optimal designs.

First principles of the AUMD

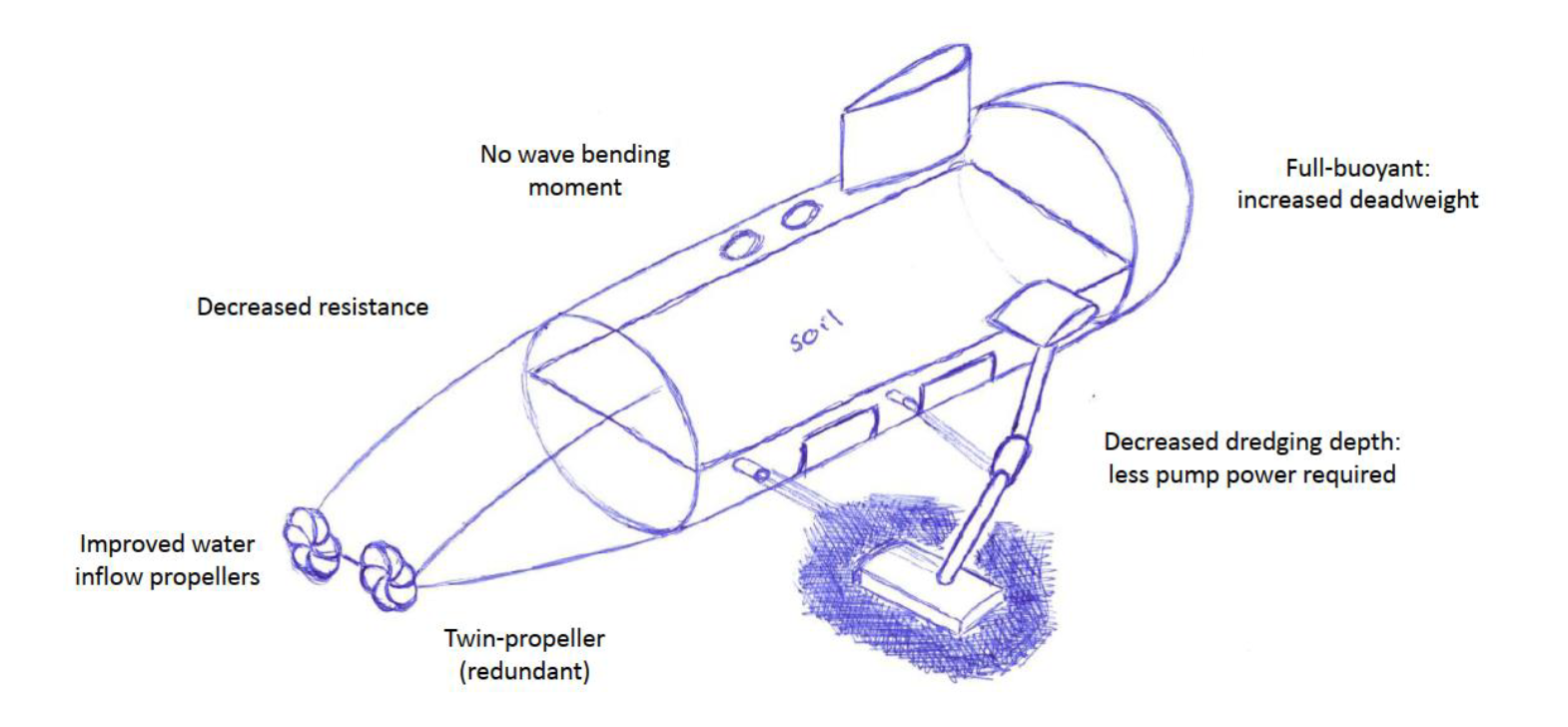

In the early stage of the development of the AUMD concept, full utilisation of the opportunities of unmanned operation was envisaged. The following arguments supported the final concept, a summary of these can be found in figure 1.

The ILO92-convention [1], concerning the crew accommodation on board ships, is applicable for every seagoing vessel above 500 tonnes. One of the criteria laid down in this convention, is the need for an open deck space for crew off duty. As the AUMD is not provided with an onboard crew, the need for such open deck spaces, nor for any other crew related accessories (accommodation space), is not present anymore. Because of such considerations, the application of a submarine design became optional and its potential was assessed.

Figure 1. Summary of conceptual design benefits.

Because of the application of a submarine design, reduced power requirements were expected because of the reduced vacuum required by the dredging pump, as well as a reduction in propulsion power. Firstly, the required vacuum would reduce due to the relatively close vicinity of the riverbed to the dredge pump. Secondly, the propulsion power would reduce due to the lack of wave making as well as wave breaking resistance, because of sailing submerged instead of in the interface between water and air.

On the opposite, some additional frictional resistance was to be expected due to the additional wetted surface area. The resulting total reduction in power requirements still had to be verified.

Following the lack of onboard crew and the resulting self-sufficiency, a significant amount of data communication should take place with respect to vessel to shore as well as vessel to vessel communication, optional remote control, situational awareness and vessel monitoring. As the current state-of-the-art in satellite data communication does not offer sufficient bandwidth or speed, a compromise was made to reduce the required amount of data to be sent over satellite communication.

Also read: C-Job Naval Architects develops customisable dredger series

This, in combination with the option to refuel and perform maintenance in close vicinity, resulted in the choice to design a dredger operating in near-shore areas. It follows from the operational profile of a near-shore dredger that it should mainly be active in the field of maintenance dredging and not in sand-winning projects.

As the hull is fully submerged, the entire volume contributes to the buoyancy of the AUMD. Especially for dredgers involved in sand winning projects, it is the deadweight of the vessel that limits the soil carrying capacity rather than the volume of the hopper. Although not considered relevant for a maintenance dredger, and therefore not considered further in this article, it is seen as one of the potential benefits of the submerged design.

Conceptual design

Starting from the fundamental insights as already depicted, several design choices were made to emphasise the design’s benefits. Firstly, since (maintenance) dredging requires a very accurate ability to dynamically position the vessel along a pre-determined track, manoeuvrability is one of the key aspects.

This, in combination with the unmanned operations, led to the choice for the installation of two (redundant) azimuthing thrusters in the aftship and two tunnel thrusters in the foreship. The combination of these (together with a proper DP/DT system, with DP2 functionality) should enable the vessel at all times, including undesired malfunctioning, to keep in position. In order to have ample thrust at low speed, the azimuthing thrusters are equipped with propeller nozzles.

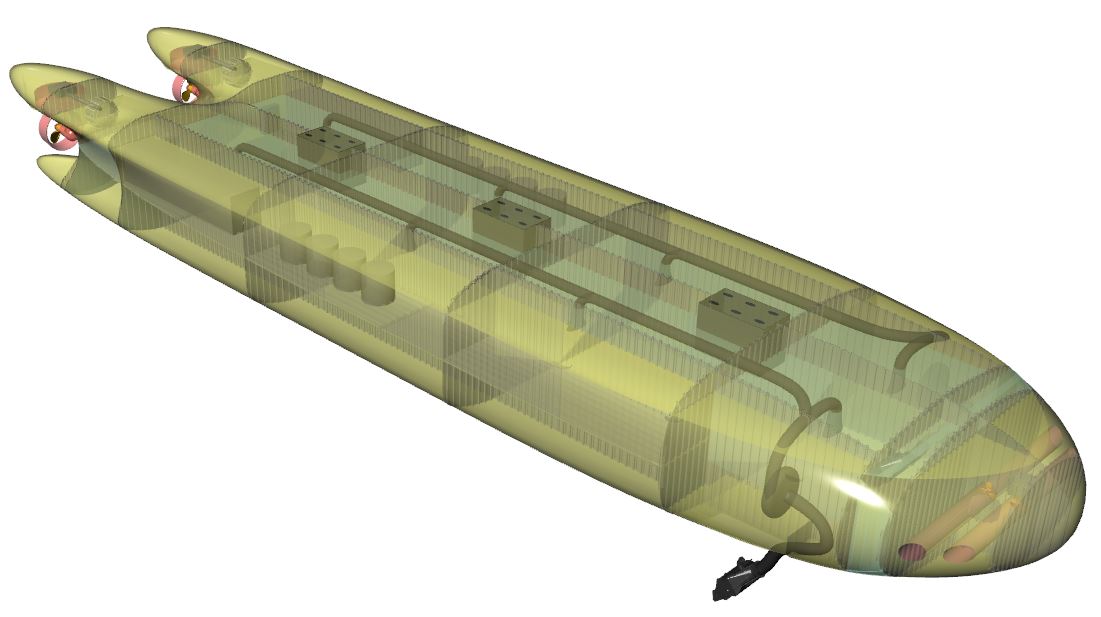

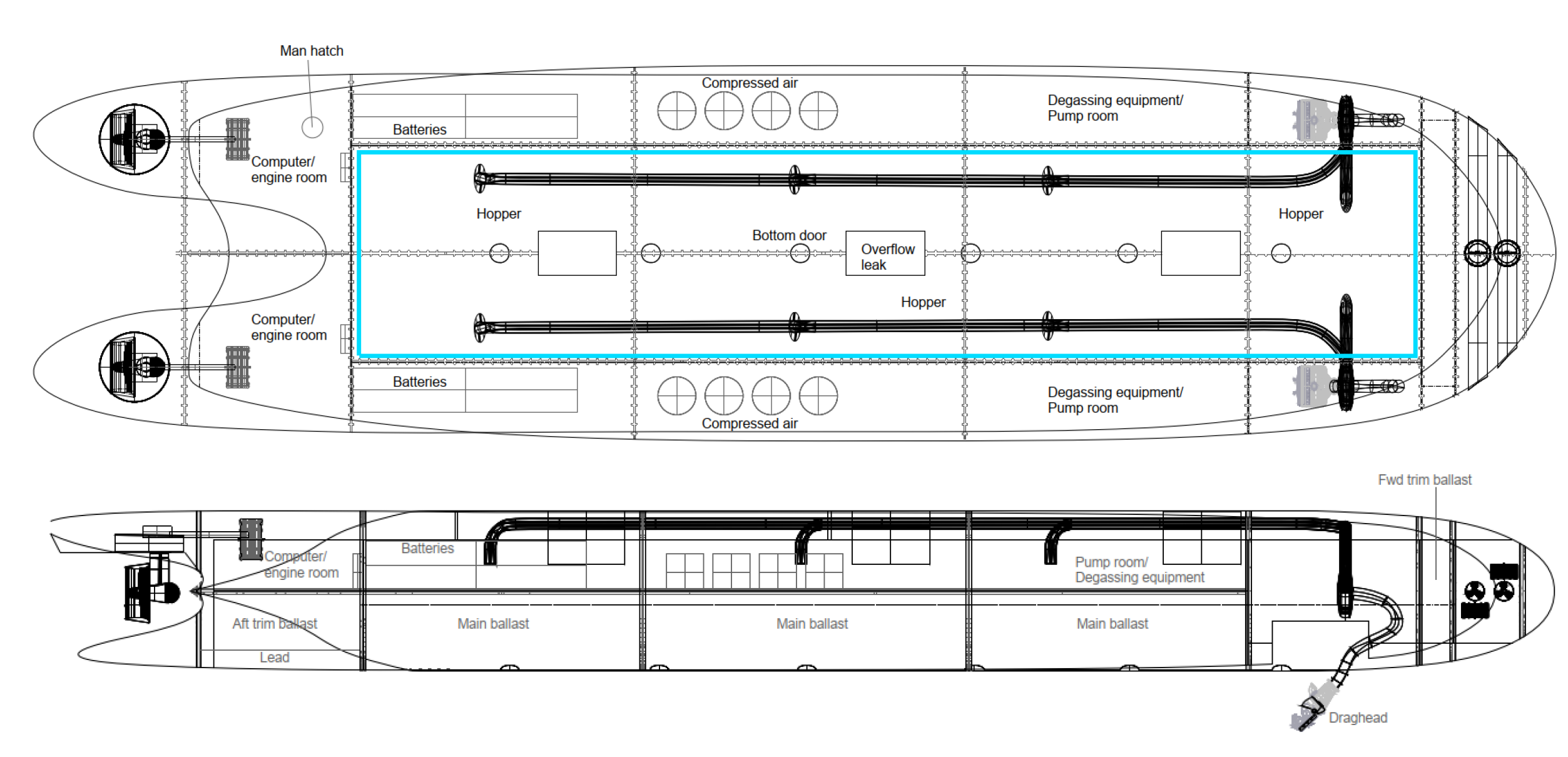

Since the AUMD will operate mainly in shallow waters and near river beds, a compromise had to be found in the hull shape considering hydrodynamic efficiency on the one hand and operating the vessel as near to the riverbed as possible. It was chosen to develop a flat-bottomed submarine as found from [2], resulting in the hull shape as can be seen in figure 2.

Figure 2. Render of concept AUMD.

As the AUMD will sail close to the seabed, the vessel might be prone to the squat effect (as opposed by the propellers) as well as the creation of a sand/water mixture flow through the propellers resulting in early wear of the propellers. Therefore, a protective propeller heel was envisioned to prevent both from occurring.

Power requirements

Since the main advantages were expected to be found in the power requirements of the AUMD, an overview was created of the main power consumers. These are the propulsion and dredging systems and for these a best practice approach was considered to estimate their requirements as accurately as possible. For the remaining auxiliary equipment, a power estimation was made based on comparable ship types.

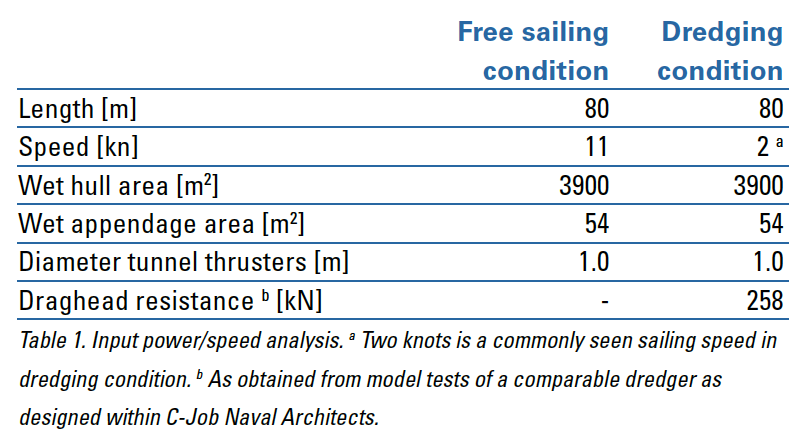

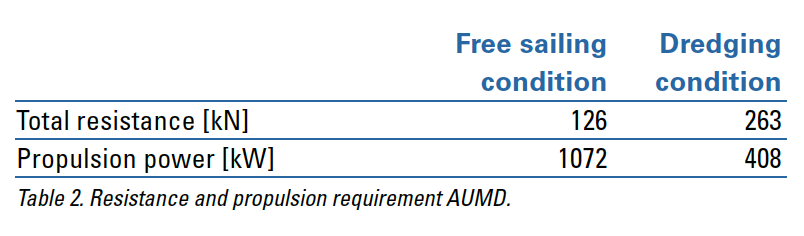

A two-fold power/speed analysis was conducted based on the Holtrop/Mennen prediction method, firstly for free sailing condition, secondly for dredging condition. From the prediction method, which is mainly built up from fiscous, form, wave and appendage resistance, the wave resistance was omitted because of the submerged operating condition. The input as indicated in table 1 was used for the determination of the total resistance in both operating conditions.

The above data results in a propulsion requirement as specified in table 2.

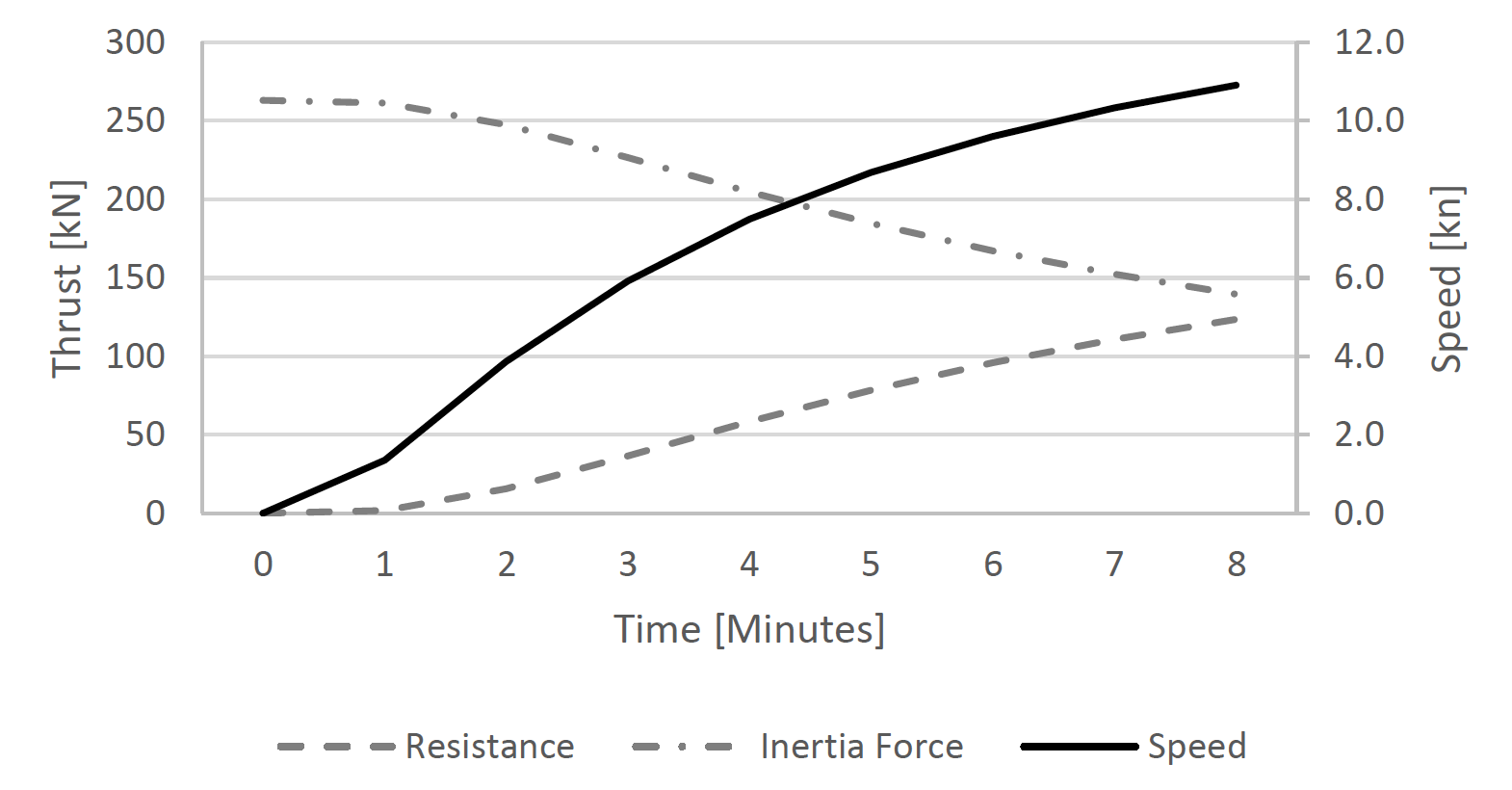

As the required propulsion power appeared low in comparison to equivalent dimensioned vessels, a verification of the resulting level of acceleration was performed. This, since the operational profile of a hopper dredger shows on a regular basis periods of acceleration from zero up to maximum transit speed. Considering the maximum available power as presented in table 2, the AUMD will be able to accelerate in reasonable time (eight minutes, see figure 3) from zero to maximum speed, which was deemed acceptable.

Figure 3. Level of acceleration.

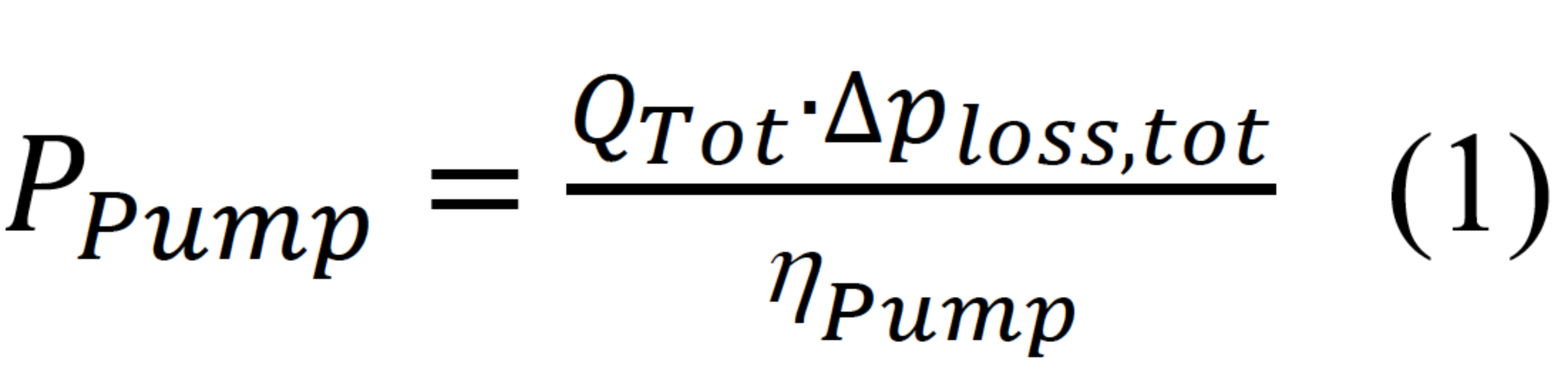

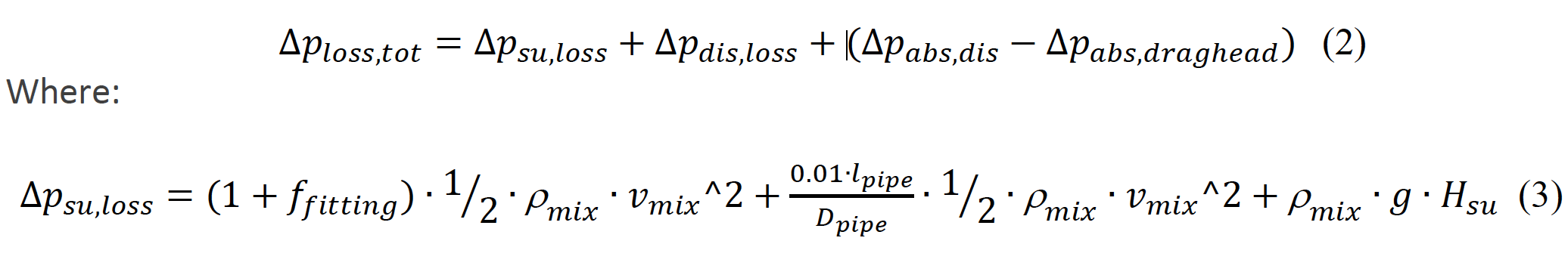

The analysis of required dredging power was based on a mathematical model as provided in [3]. Herein, the formula (1) is considered in the determination of required dredge pump power:

Where QTot is the total mixture flow, which is a parameter solely dependant of the dredged soil and the hopper dimensions. Since these are not directly influenced by the current AUMD concept, the exact details are deemed irrelevant here. However, the parameter Δploss,tot, which is the pressure loss over the dredging system from draghead to discharge, is strongly affected by the current concept.

The pressure loss is divided in the following components:

Considering the input data from table 3, a dredge pump power of 261 kW was obtained. Divided over two dredge pumps, this results in two drive trains each having a power of 135 kW.

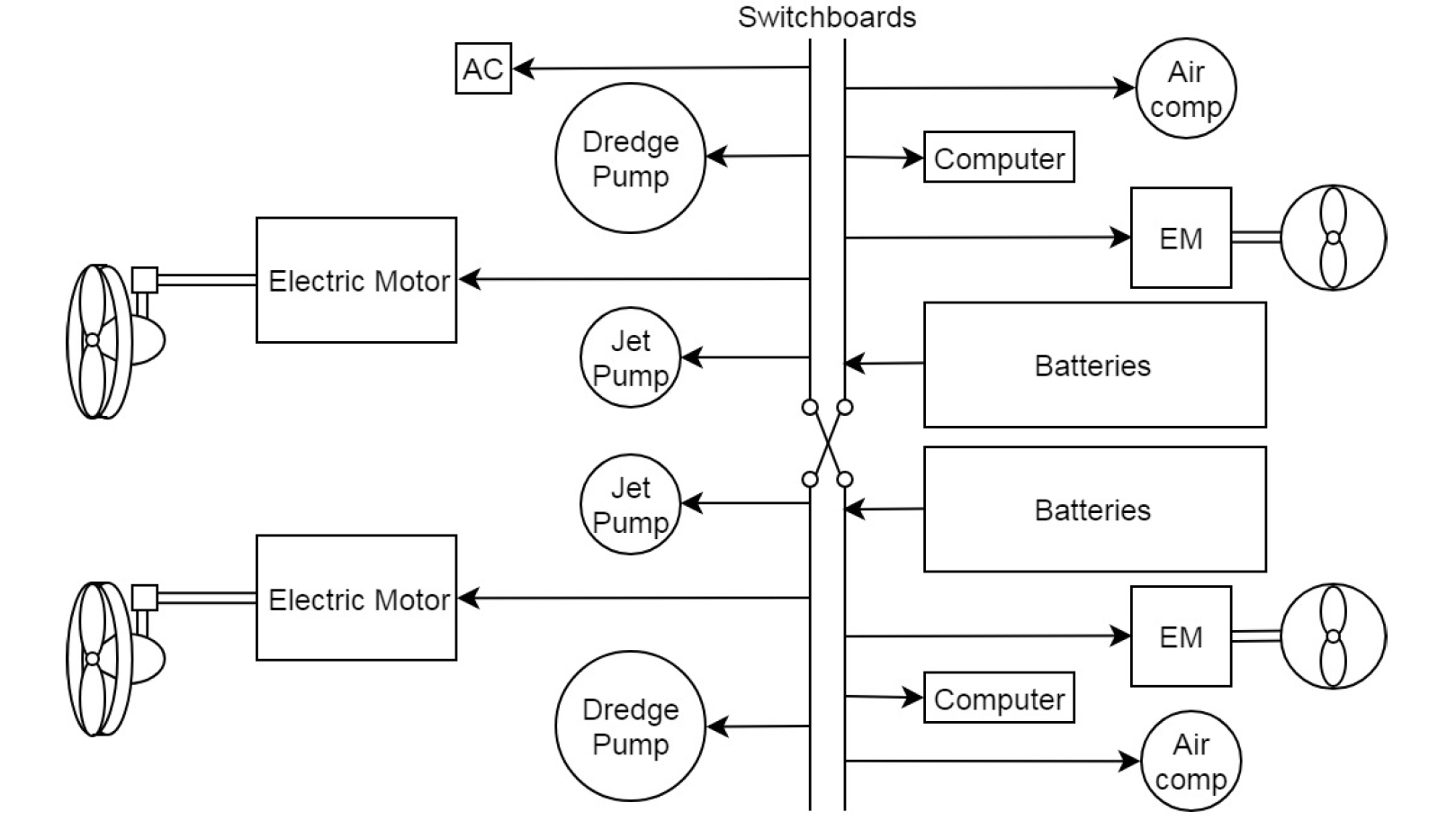

In order to be sufficiently redundant, as in emergency conditions no repairs can be performed due to the lack of onboard crew, the single line diagram as indicated in figure 4 was considered.

Figure 4. Single line diagram.

In order to be able to determine the capacity of the batteries indicated, an estimation of the electrical load balance was made, considering the main operational conditions of the AUMD. This overview is given above. The total required power appears to be 1600 kW. Principal dimensions and general arrangement Table 5 indicates the principal dimensions of the AUMD. For comparative purposes, the main characteristics of the reference vessel are indicated in the table as well. Here it can be clearly seen that with respect to the power supply a considerable reduction was achieved.

Figure 5. General arrangement of the AUMD.

Buoyancy, trim and heel Submarines are very sensitive to trim, heel and buoyancy changes. Therefore, ample attention has been paid in this concept phase to these aspects. Similarly, the automation system should be capable of providing sufficient stability and buoyancy during all operational conditions as well, which requires speed analysis as well as sufficient pump and compressor capacity. Especially in dredging condition, this will result in detailed monitoring of trim and heel, resulting in adjustments in ballast. In order to enable the AUMD to control all motions, two trim tanks (fore/aft) and central ballast tanks (spread over portside and starboard) have been arranged.

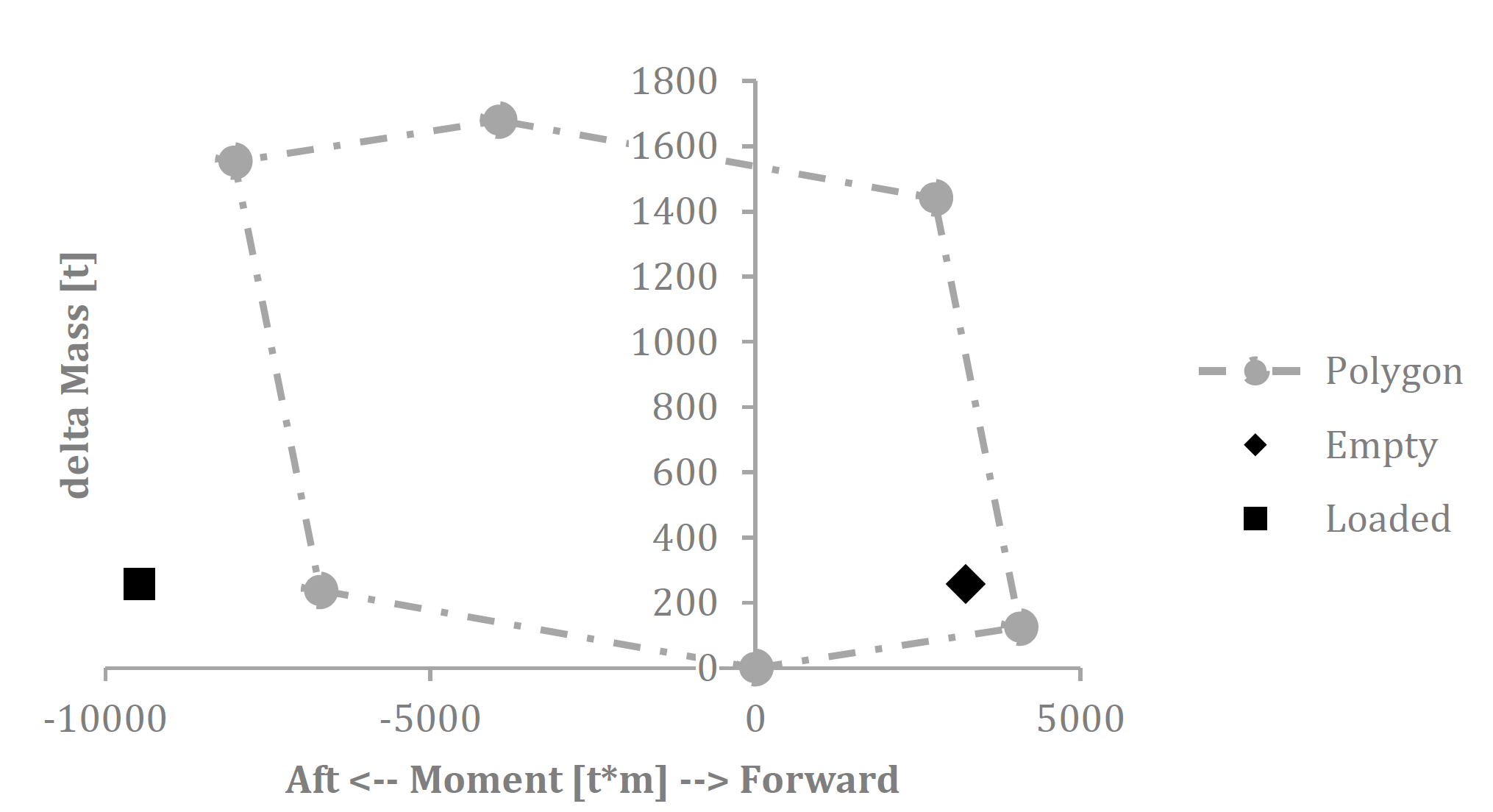

Figure 6 shows the trim polygon of the AUMD, which indicates the operable ranges having zero trim and enough buoyancy. As can be seen, the current concept shows a trimming moment by the bow, which might be solved by increasing the length of the vessel and apply some more ballast tanks (or fixed ballast) in the aft.

Figure 6. Trim polygon of the AUMD.

One of the benefits of the current design is the AUMD’s open top side of the hopper, herewith no sloshing effect will be generated in the hopper, which is beneficial to the control of trim and heel.

Global hull girder loads

The dimensioning of the AUMD’s hopper anticipates on the new options in the general arrangement of the vessel. As such, the hopper was made longer and narrower compared to similar vessels of this size. For instance, the ratio over the hopper and vessel length to width ratio is beyond unity, whereas for comparable vessels an average ratio of 0.83 is found, which is a direct consequence of the area involved in accommodation space.

This higher ratio is directly in relation to the global hull girder loads, since by these means the buoyancy distribution is more equal to the soil’s weight distribution, which induces less bending moment. As a direct consequence, the amount of required steel reduces, resulting in a relatively higher payload. Especially for higher density soil types (that is, sand), this leads to significant reductions in steel weight and herewith fuel consumption.

Overflow principle

Since the AUMD appears to have ample buoyancy, an open top hopper appeared to be feasible. This also enabled the provision of an overflow system, that is, a means to relieve pure water from the hopper, by means of openings in the outer hull. Although a maintenance dredger is involved in dredging of low-density soils with large settling times, such a system seemed feasible especially when taking care of large settling distances.

Such long settling distances are enforced by providing the openings at the farthest distance relative to the location of discharge of the soil.

Specific requirements for unmanned operations

Because of the unmanned, autonomous operations, several design aspects should get special attention. This is because crew cannot anticipate on failures of equipment, collision avoidance, maintenance and more. The following aspects have been considered in the current concept.

Since the AUMD will be in port on a regular basis (expected is to have the vessel in port on a daily basis), the application of a docking station for recharging and modular equipment becomes attractive. This allows equipment to be maintained, replaced and recharged without (much) consequence for deployability.

This resulted in the choice for a fully electric design, powered by batteries. In addition, with a fully electric system, the amount of rotative machinery (which is prone to maintenance) is reduced. Similarly, the entire dredging system (pipelines, dragheads) will be fitted out in such a way that it can be easily exchanged in port and maintenance can be performed on shore.

Also read: Offshore structures may be protected by Autonomous Guard Vessels

For emergency purposes, which could consist of lack of power, hull structural failure, machinery failure, etc., an option should be made available to access the AUMD from the outside. Therefore, space reservation for a diver’s lock has been integrated in the design to ensure access from within the harbour environment (inspection), but also in submerged condition. Further requirements to accessibility of the vessel are still pending as the vessel is not intended to provide access to people on a daily basis, however, access needs to be guaranteed at least for maintenance purposes.

In order to enable the AUMD to navigate safely, which means it will have sufficient capabilities in detecting traffic and other obstacles and other vessels will be able to detect the AUMD, ample provisions have been considered. The main situational awareness technology on board will exist of radar, AIS, optical cameras combined with a forward-looking sonar.

To improve the AUMD’s range of data communication, a preliminary option was considered to have a towed surface communication vehicle (TSCV) carrying all indicated situational awareness systems with a wired connection to the AUMD. This way, for instance a regular 4G or 5G network might be used for communication purposes and other vessels will be able to detect the TSCV and herewith the AUMD.

Total cost of ownership

One of the key advantages envisioned for the AUMD, is the total cost of ownership. In order to quantify this aspect, a CAPEX/OPEX study was performed. Although in the current status of design only estimates can be provided, it gives some insights in the economic feasibility of the concept. So as not to provide an overly optimistic view on the operations of the AUMD compared to conventional dredgers, a most conservative approach was considered in the cost estimate, which at all times should result in a lower actual cost of ownership of the AUMD.

The total costs are divided in initial investment costs (CAPEX) and operational costs (OPEX). By these means, both the total costs are estimated as well as the return on investment (ROI). For the ROI, a period up to ten years is deemed acceptable for the AUMD, as such reducing the economic risk of taking the step towards autonomous shipping. The differences in CAPEX considered here consist of:

- Reduction hull construction costs (+ interior etc.) accommodation areas;

- Increased hull construction costs due to complex submarine design;

- Cost comparison dredging equipment, resulting in a minor cost reduction;

- Increased costs for power supply, comparing marine gas oil (MGO) in reference vessel to battery package in the AUMD;

- Additional costs for situational awareness technology;

- Cost increase due to overhaul of main machinery once in operational lifetime;

- Cost increase due to expected decrease of AUMD’s scrap value.

The differences in CAPEX between the conventional reference vessel and the AUMD resulted in a total of € 5.2 million.

The differences in OPEX considered in this study consist of:

- Cost reduction in fuel (battery charging);

- Maintenance costs are assumed to be equal, although due to less rotative machinery, actual costs are expected to reduce;

- Reduction in crew costs, considering that some shore-based crew is required for monitoring and maintenance purposes;

- Increased costs in automation software.

The differences in OPEX between the conventional reference vessel and the AUMD resulted in a total of € 0.8 million per year.

Considering the above cost breakdown, the ROI is achieved after 6.5 years of operation, which is a very promising period of time. Considering this ROI, the concept is deemed economically feasible. However, more in-depth research is required to prove the assumptions made.

Also read: Interactive Viewer provides 360-degree experience of ship design

Many challenges yet to be solved

In conclusion, the Autonomous Underwater Maintenance Dredger has high potential, where it should be noted that although promising from a technological and economical point of view, many challenges need to be solved. Amongst others these are related to the acceptance of autonomous operations by society, regulatory challenges (allowance of submarines in port), legal aspects for autonomous/unmanned operations as a whole, but also availability of port facilities (automated mooring, battery charging facilities and vessel monitoring agencies).

However, these are all expected to be solved in the upcoming years by force of the global maritime industry. Furthermore, the concept is just one of the examples showing the opportunities of autonomous shipping.

C-Job foresees many other opportunities, which could bring even more benefits; for dredging in particular, for example in relation to higher density soil types, deepsea (mining) trades, but also in the scale size of the dredger. Although C-Job acknowledges many challenges still need to be overcome, the concept of the AUMD does show promise in itself. Moreover, the concept underlines the possibilities of autonomous unmanned shipping in the future.

References

- International Labour Convention (ILO) No. 92 – Convention concerning crew accommodation on board ship (Revised 1949) – Part III, Article 12.

- H. Sutton, US Navy diesel-electric submarine concept shallow water submarine (SWS).

- S. Miedema. OE4607 Introduction dredging engineering, MSc Offshore & Dredging Engineering, Delft University of Technology, 2016.