Decarbonisation of shipping is one of the greatest maritime challenges and the demand for low carbon solutions is growing. The European research project Wind Assisted Ship Propulsion (WASP) investigates how wind propulsion technology and, thus, solutions can become more commercially attractive in the future for the North Sea region.

This article was the lead article in SWZ|Maritime’s March WASP special written by SWZ editor and maritime journalist Sander Klos. Read the full article below.

The Interreg North Sea Europe programme, part of the European Regional Development Fund (ERDF), facilitates transnational cooperation between 49 regions in seven countries in the North Sea region. It aims to tackle the main challenges these regions face within the priority themes “Thinking about growth”, “Eco-innovation”, “Sustainable North Sea area” and “Green transport and mobility”. The WASP project is funded by Interreg. The other half of the funding comes from the project partners to the tune of 5.4 million euros. The project started in June 2019 and will run until the first quarter of 2023.

Studies on five ships

Five shipping companies participate in WASP with different wind propulsion technologies (WPTs). First, WASP partner Van Dam Shipping installed an eConowind fixed two-wing Ventifoil system on the 3600-DWT general cargo ship Ankie.

Boomsma Shipping also installed an eConowind Ventifoil system, which includes two wings integrated in a specially designed Flatrack from which a folding Ventifoil can be deployed. The WPT installation was finished in January 2021 on the vessel Frisian Sea.

Also read: Boomsma orders VentiFoil wind-assisted propulsion with Flatracks

In May 2020, Scandlines installed a 30-metre tall Rotor Sail from the Finnish company Norsepower on the ferry Copenhagen.

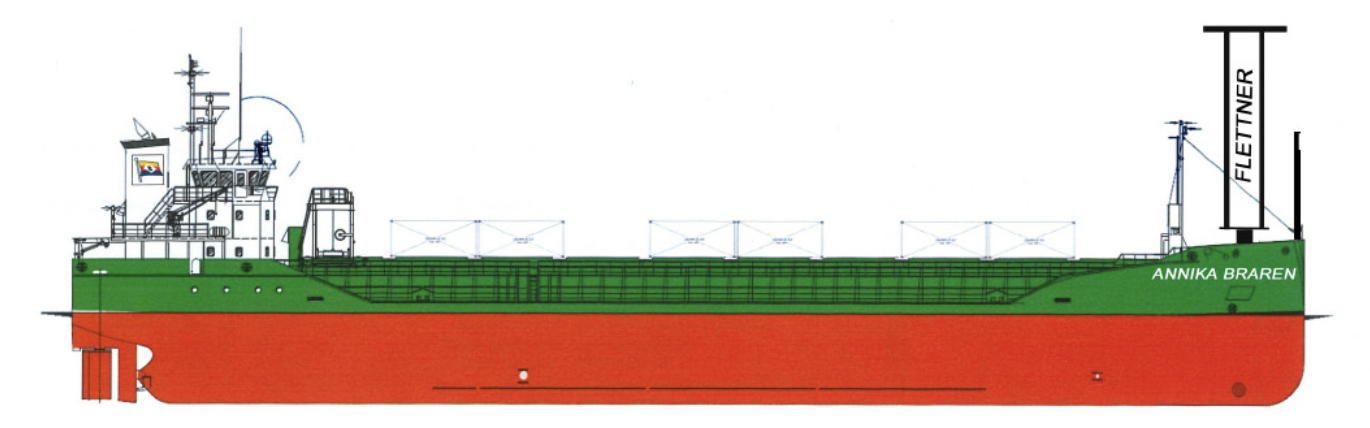

Rörd Braren installed a Flettner Rotor on the Annika Braren in February. Finally, Tharsis Sea-River Shipping contracted eConowind to install two of their wind-assist 3 x 9-metre TwinFoil units on their 88-metre, 2364-DWT diesel-electric general cargo vessel Tharsis. Installation of this system is the last of five installations under the WASP project and according to eConowind this is scheduled for May 2021.

The Annika Braren has a Tier III compliant engine with selective catalytic reduction (SCR) and efficiency monitoring. It has an EEDI optimised design of propulsion and hull, burns marine gas oil (MGO) and is equipped with ballast water treatment and no oil pollution interface technology for shaft, controllable pitch propeller (CPP), rudder and bow thruster. The Flettner rotor will reduce fuel consumption and emissions.

Wind is money

Within WASP, Netherlands Maritime Technology Foundation is the project coordinator and also the point of contact for the fourteen project partners from the Netherlands, Belgium, Germany, Denmark, Norway, the United Kingdom and Sweden. The project brings together universities, wind-assist technology providers and ship owners to research, trial and validate the operational performance of a selection of wind propulsion solutions on five vessels, thus enabling wind propulsion technology to penetrate the market and contribute to a greener North Sea transport system through harvesting the regions’ abundant wind potential.

The project objectives are:

- Proven WPT concepts that lead to greening of (North Sea region) sea transport;

- Identify the viable business cases for (hybrid) WPTs; and

- Facilitate a level playing field for WPT with policy instruments.

Savings

By setting up WPT trials, the project will provide validated research data. This can improve concepts and create a viable business case, which should lead to an acceleration of market uptake. By the project’s end in the first quarter of 2023, it is hoped the following savings will be achieved based on the one ferry and four cargo ships with WPTs in operation:

- 27,634,805 kWh generated with WPTs in WASP;

- CO2 reduction of 17,637 tonnes; and

- 5594 tonnes of heavy fuel oil/marine diesel oil saved.

Also read: Tharsis Shipping orders new type of eConowind wind-assist installation

First ships

After 1.5 years, WASP is making good progress towards its objectives. It already started to deliver on compulsory outputs. This also includes the installation of WPT on the vessels of Van Dam and Scandlines. After installation, the system became operational in the North Sea region. The system, mechanics and electronics were tested on both vessels in different conditions, fine-tuned and updated.

The impressive Norsepower Rotor Sail on Scandlines’ Copenhagen ferry.

After monitoring, measuring and recording wind condition, fuel consumption and vessel speed, the first test trips have shown positive effects. Challenges remain with further optimisations needed to get the system operating to full satisfaction. Delivery of the WPT installation on the vessels of Boomsma, Rörd Braren and Tharsis takes place in the first half-year of 2021. In the meantime, the development of the performance indicators continues in collaboration with the Joint Industry Project WASP project led by MARIN.

Data for knowledge

The development of a viable business case for WPT is proceeding accordingly in order to understand what factors should be considered and what factors can drive the installation of such technologies.

Vasileios Kosmas of the Kühne Logistics University says: ‘Fuel savings expectations, a corporate green agenda and the potential brand value enhancement represent key drivers for companies to invest in WASP technologies. Policy makers and customers are identified as key stakeholders that can incentivise companies toward this technological adoption. Other important stakeholders with an influential role in accelerating this adoption process are insurance companies, classification societies and the crew. The uptake of WASP technologies can also benefit from a fast and effective decision-making process grounded on direct communication between the technical experts and the top-management of the company.’

Policy makers and customers can incentivise companies towards technological adoption

Kosmas: ‘Furthermore, the construction of a viable business case requires a thorough assessment of possible technical, operational and financial risks. Last but not least, a precise statement about the payback period of the investment cannot be made. The payback period is dependent on different factors such as the actual obtained bunker savings, which vary according to the technology installed, ship size, routes of operations, weather conditions, etc.’

Different feed-ins are being developed to be integrated into this business model. Such as decision support models, investment/fund/finance tools and solutions, market conditions, fuel/emission saving predictions for different scenarios, etc. In the end, the performance of the WPT, emission reduction and power and fuel savings strongly influence the business case.

Characterisation, simulation and in the end validation of the performance will make the results of different technical solutions transparent and comparable. This will be a major achievement of the WASP project and will strengthen the business case.

Characterisation, simulation and validation will make the different technical solutions transparent and comparable

Ten recommendations

The project partners are promoting WPTs and WASP. On a national and international level, several meetings with key stakeholders from the shipping industry and the organisations delivering clean technology for shipping have taken place. Barriers that block WPT uptake in the market and the political regulations that are needed to overcome these barriers were discussed. This information was used in a policy brief about wind technologies for cleaner shipping, focusing on regulatory actions to promote WASP.

This brief carries ten regulatory recommendations:

- Introduce a significant carbon levy, which is to be raised annually.

- Introduce a CO2 dependent speed limit or engine power limit at sea.

- CO2 reduction should be aligned with the 1.5°C goal of the Paris Agreement.

- More public research and development funds for “non-fuel” propulsion technologies.

- New 1.5°C compatible EEDI targets for 2025/30 and beyond.

- Include shipping in a flag neutral emissions trading system.

- Stricter regulations for ship emissions to air and water.

- New port fees based upon emitted CO2, NOX, SO2 and particulate matter.

- Stop public support for fossil fuels and fossil fuel infrastructure.

- Include life-cycle assessments when assigning CO2 savings.

More facts

The report “New wind propulsion technology – A literature review of recent adoptions” and a Master thesis on ship owners and their experiences and expectations with respect to wind propulsion are published at https://northsearegion.eu/wasp/output-library-publications/. The project has also been highlighted in policy discussions/documents and presentations made for EU level projects.

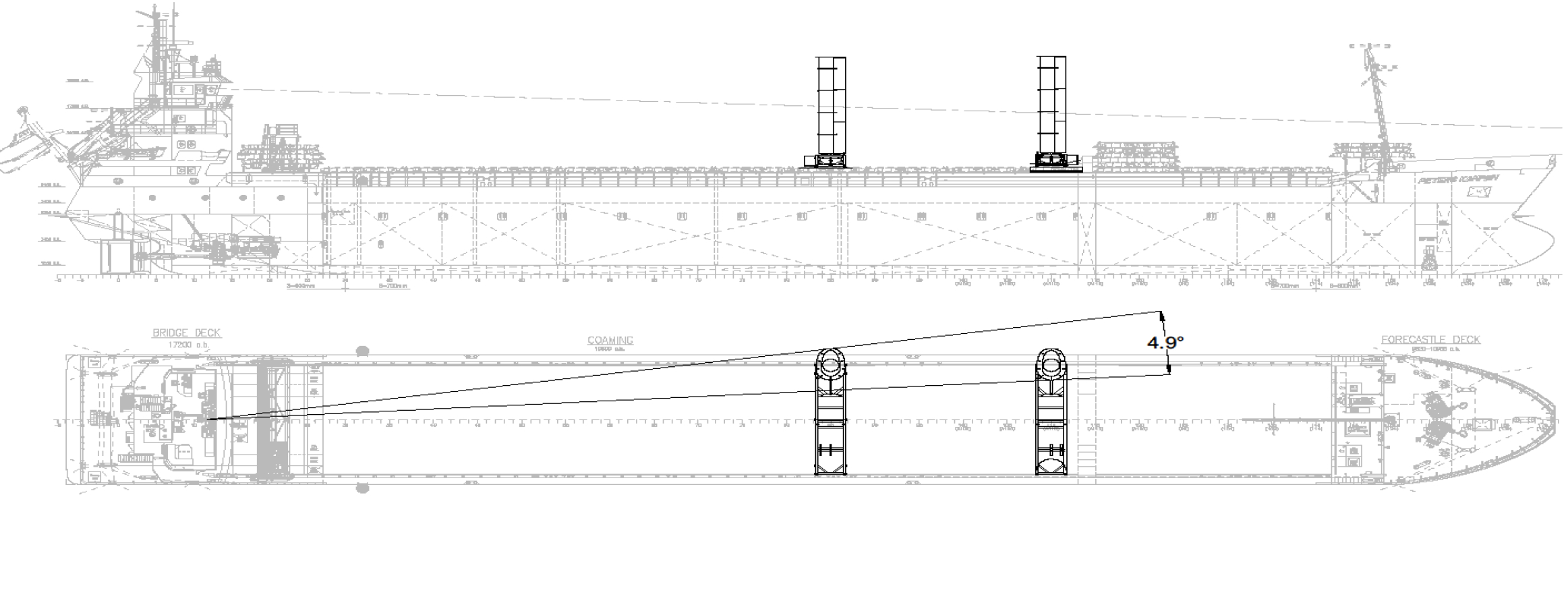

This drawing highlights the bridge visibility issue of the Frisian Sea of shipowner Boomsma, which uses foils with boundary suction (illustration KU Leuven).

In November 2019, during the 31st IMO Assembly, a statement was delivered by the Comoros Permanent Representative, highlighting the significance and potential for wind propulsion technologies, raising awareness among IMO delegates. This was followed in January 2020 by the submission of IMO MEPC75 Inf.26 document that highlights key aspects of WPT development, with an explicit reference to the WASP project, to help achieve the ambitious goals set out by the Initial IMO GHG Strategy and including an introduction to WASP activity. Now, project partners continue to disseminate the IMO MEPC75 Inf.26 document.

‘Find out if they work on the river to Duisburg’

From the North Sea between Goole on the Humber (UK) and Duisburg on the Rhine (Germany), Jan Albert Bosma and his father Gerrit, co-owners of Tharsis Shipping, tell us more about the “winging” of the diesel-electric sea-river vessel Tharsis (88 metres, 2364 DWT). Meanwhile, Director Frank Nieuwenhuis of eConowind reports that the system for the Tharsis is almost ready and can be installed in May.

Nieuwenhuis: ‘The Ventifoils are very thick aircraft wings, which are placed vertically. The force is therefore horizontal and helps with the propulsion. In order to make optimal use of these thick wings, we have applied the principle of boundary layer suction. This “pulls” the airflow around the wing, so it does not “bypass” and instead gives maximum force: up to four or five times the force per m2 of a normal sail. The wing must always be set optimally in relation to the wind and this is done automatically. The raising and lowering is also done automatically; the captain only has to indicate that the sails should be set.’

The Tharsis gets a Twinfoil, an innovation for eConowind, that works with a wing with a flap principle, similar to those used by aircraft during landing and take-off. Setting the wings optimally relative to the wind is done by a small third steering-wing, which is fast and reliable. The Dutch NG shipyard will install the system that must stay under the 2500 kg total weight as needed for vessel operations. The units are integrated in an aluminium Flatrack from which the folding Twinfoils can be deployed.

Excessively stable

The Bosmas: ‘Boomsma’s Ventifoils have a fan. With our TwinFoils the wind does that itself, so the control is energy neutral. The system is also more compact than the one with Ventifoils. In principle, both units can be stored stacked on a hatch. The hatch width sets the height of the wings at eight metres, so that the total height will be around eleven metres depending on the draught.’

‘The wings will mainly be used at sea. On the river to and from Duisburg, the wind is much more volatile, but on some long stretches without too many bridges, it may be possible. We are going to find out.’

During the measurements for the WASP research by the University of Leuven, Bosma benefits from the recently purchased monitoring system, which sends numerous sailing data to a remote server. ‘In Leuven, they will make a digital twin of our ship, which enables them to test theoretical calculations against our practice.’

In Leuven, they will make a digital twin of our ship, which enables them to test theoretical calculations against our practice

Bosma does not expect stability problems from the pressure on the sails. ‘On the contrary. Because of our heavy cargoes, we have a low centre of gravity and the ship is quite excessively stable. The pressure on the sails will temper that stability’.

Bosma tries to make the most of the tides and can already picture how this will work: ‘Now and then we stop off under the British coast, quietly on one generator set. Soon we will have wings that will blow us in the right direction for free. Especially interesting will be to see how much the tipping point of starting a second generator will shift.’

Boomsma is testing and training

Boomsma Shipping installed its first two eConowind Ventifoil wind-assisted propulsion units on the Dutch flagged Frisian Sea, a 6477-DWT general cargo vessel, in January. In early March, Ton Boomsma, co-owner and CTO of the company, answered some questions about the first observations made on a journey to Stade, Vasteras, Sillamae, Szczecin, Skulte, Schiedam, Molde, Riga and Bayonne in February.

‘Upon departure from Harlingen, the weather was stormy. It was rough outside and the vessel was rolling. They had some small problems with the Ventifoils, so they were not in use continuously. Later, they ran into easier weather with about 5/6 Beaufort (see video on LinkedIn). From 3 Beaufort and up, the foils gave a noticeable effect and with 4 Beaufort they really delivered. The power rose to 7 Beaufort and flattened after that.’

About the effects north- or southbound, Boomsma expects some data in early March. The system has expecienced some hiccups. ‘Normal for such an innovative system. We got some alarms in the hydraulics, the wind meter on one of the units seems off and there is still some calibrating to do. And we need some support beams for the frame of the Ventifoils when in stored position.’

The crew needs time to adjust to the new outfitting as well. ‘We noticed the crew likes to learn and is becoming experienced in placing and moving the units. At this moment, it takes them about forty minutes to store the foils. We expect we can gain some more time here.’

The crew needs time to adjust to the new outfitting as well

Boomsma says the foils don’t influence the behaviour and movement of the ship. ‘Except for the higher speed and lower fuel consumption.’ In this testing period, it’s hard to say anything about the gain in fuel consumption. Boomsma mentioned in a press releases a number of ten per cent.

‘Personnel from eConowind is aboard for constant monitoring. Yesterday we were told: “On some trajectories we could measure hour-on-hour in varying wind speeds and found a maximum reduction of 13.5 per cent”.’

Two years of testing

Tessa Remery, project coordinator, adds: ‘With the help of the WASP project, we will be testing the performance over the next two years. This innovative technology must work in our daily operations and in different wind conditions. We hope to achieve savings of around ten per cent.’

We hope to achieve savings of around ten per cent

Ton Boomsma, co-owner and CTO of the company: ‘The installation of the Flatrack was relatively easy. We now expect that the units will offer optimal results due to their placement. Once the crew has gained experience, we do not expect any problems when handling the units with our hatch crane.’ The new Flatrack design, based on Boomsma’s concept, has now been added to eConowind’s product portfolio as a standard product and can be used on more ships.

Up to twenty per cent fuel savings

The Norsepower Rotor Sail on the hybrid ferry Copenhagen works in perfect conditions according to Scandlines CEO Søren Poulsgaard Jensen. ‘The technology has the optimum effect when it is windy and the wind comes from the side. The route between Gedser to the north and Rostock to the south is almost perpendicular to the prevailing wind from the west, giving us favourable conditions for using rotor sails.’

These systems are expected to deliver four to five per cent fuel savings – corresponding to the same amount of CO2 – on average, and more than twenty per cent in optimal wind conditions.

Scandlines’ COO Michael Guldmann Petersen expects a four to five per cent reduction in CO2 emissions. ‘We are happy that the system is fully automated and we’re expecting little in the way of technical problems. The last month of operations has been quite smooth and we see that continuing throughout the test period.’

Scandlines‘ naval architect Rasmus Nielsen was content with the installation ‘in just a few hours during a scheduled overnight stop in May 2020, following meticulous preparation. Earlier, the ferry had been prepared during a yard stay, where a steel foundation (21 tonnes) was installed and cables were pulled. The rotors weigh 42 tonnes.’

Asked for his opinion so far, Nielsen thinks it’s too early to draw final conclusions about the performance. ‘We take at least one year before doing that. However, the feedback from the vessel is promising. One focus of the WASP project is the validation of performance data. This will be beneficial for our case as well.’

That data will help to decide about other installations. Poulsgaard Jensen: ‘We have to await the final assessment of the operational performance of the Copenhagen. If the results are according to our expectations, we plan to install another rotor sail on sister vessel Berlin, which operates on the same route.’

Projects like WASP can help to collect more proven data on WPT and at the same time raise awareness within the maritime industry

Nevertheless, architect Nielsen thinks it’s necessary to have more WPT installations that can be used as benchmarks. ‘That’s why there is still so much uncertainty about the expected performance and the corresponding business case. Projects like WASP can help to collect more proven data on WPT and at the same time raise awareness within the maritime industry.’

Picture (top): The foils on the Frisian Sea (taken by the captain).