Stolt Tankers has been commissioned by chemicals company BASF to help design and build a new tanker that can operate in extremely low water levels in the river Rhine. The ship will be built by Mercurius Shipping Group and is to be delivered in 2022.

The Rhine is a key waterway for transporting chemicals in Europe. During dry weather, barges are unable to fully load, increasing transport costs and delaying products. The new barge will still be able to pass the critical point in the Rhine near Kaub carrying 650 tonnes of cargo even at a water depth of 1.60 metres, which is significantly more than any other tanker available today.

At average water depths, the tanker has a transport capacity of around 2500 tonnes, twice that of conventional inland vessels. After delivery, Stolt Tankers will operate it exclusively for BASF.

Low water levels to occur more frequently

‘This innovative inland tanker is designed with a unique draught and will set a new mark for the transport of cargo on the River Rhine, especially when water levels are low. Keeping products moving even when river levels are becoming more unpredictable,’ says Lucas Vos, President Stolt Tankers.

Dr. Uwe Liebelt, BASF European Site and Verbund Management, adds: ‘Following our experience with the low water levels of the Rhine in 2018 and based on our assessment that such events may occur more frequently in the future, we have taken a whole range of measures at the Ludwigshafen site to increase the security of supply for production. An important element of our considerations was to have a ship that can still reliably transport substantial quantities even at the lowest Rhine levels.’

High load, shallow draught

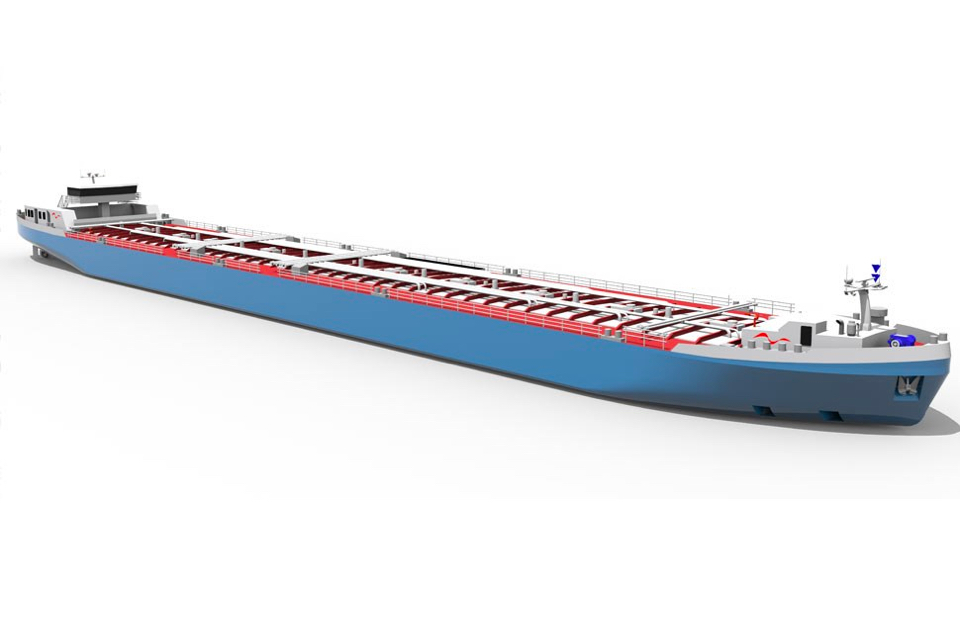

The main objective for the development of the new ship was to provide a high load-bearing capacity coupled with a shallow draught, ensuring safe operations and full manoeuvrability at all times, even in extremely low water. The dimensions of the new ship are 135 metres by 17.5 metres, which is considerably larger than the standard tankers on the Rhine, which are usually 110 metres by 11.5 metres.

In order to achieve a high load-bearing capacity with these ship dimensions, a hydrodynamically optimised hull with an adapted propulsion was developed. The construction is lightweight, with high structural stability ensured by applying methods from seagoing shipbuilding, maximising cargo carrying capacity.

Also read: Huge order for Concordia Damen: 40 inland LNG tankers for Shell

The ship is powered by three electric motors, which are fed by highly efficient stage V diesel generators of the latest generation with exhaust gas aftertreatment. The ship is equipped with ten stainless steel tanks and three separate loading systems offering maximum flexibility of the chemical products it is able to transport.

Picture by Technolog.