Developments in digital techniques are growing exponentially and possibilities seem endless. In the opening article of SWZ|Maritime’s latest special, we provided insight in the digital transformation in the maritime world.

An enormous amount of terms and concepts has arisen which sometimes make it impossible to see the wood for the trees. In the opening article of SWZ|Maritime’s October Digital transformation special, our editor Annelinde Gerritsen provides an overview of technologies in easy to understand language. Read her article below.

People are creatures of habit. When AutoCAD was introduced, it took a while for everyone to switch to this, and some didn’t switch at all. Actually, traditional manual work is also much more fun, but it takes a lot of time (and therefore money, which is the priority in today’s world). Developments are now much faster and switching to new techniques requires constant adjustments and appeals to our ability to learn, which costs a lot of energy and confuses our daily routine. Switching to digital ways of working requires a digital transformation.

The current corona crisis is accelerating the digital transformation. It provides both opportunities and limitations. We are being forced to meet online and are experiencing both advantages and disadvantages as a result. We no longer have to travel, and within our editorial staff with members from all over the country, for example, that saves a lot of travel time, fuel, travel costs and CO2 emissions. Another advantage is that we can easily ask a colleague a question during an online meeting via the chat without disrupting the whole meeting.

Seminars are also easier to attend and more accessible; we see faces that we would not otherwise see. If we really do not have time to participate, we can do so afterwards by watching a recording.

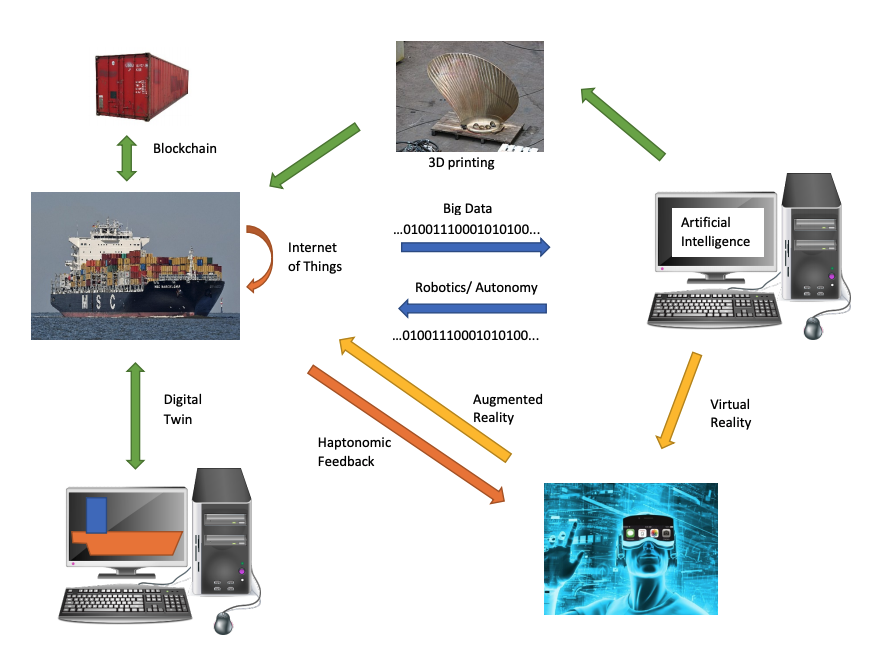

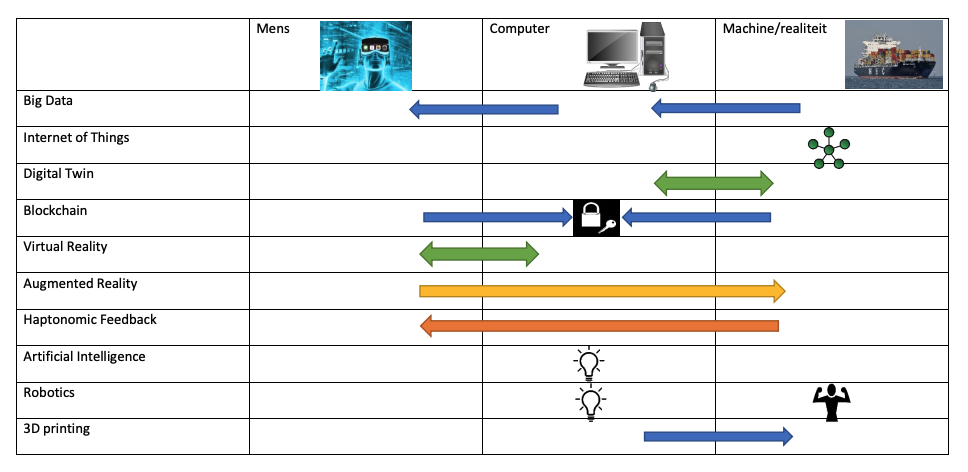

Overview of terms used within the digital transformation.

What is missing, of course, is personal contact. During some online meetings breakout rooms are used, which try to replace the network function and succeed in this to a large extent. But the non-verbal communication, sensing what people mean instinctively of being among them remains a shortcoming.

Interaction between man, computer and reality.

Preconditions for handling data and information

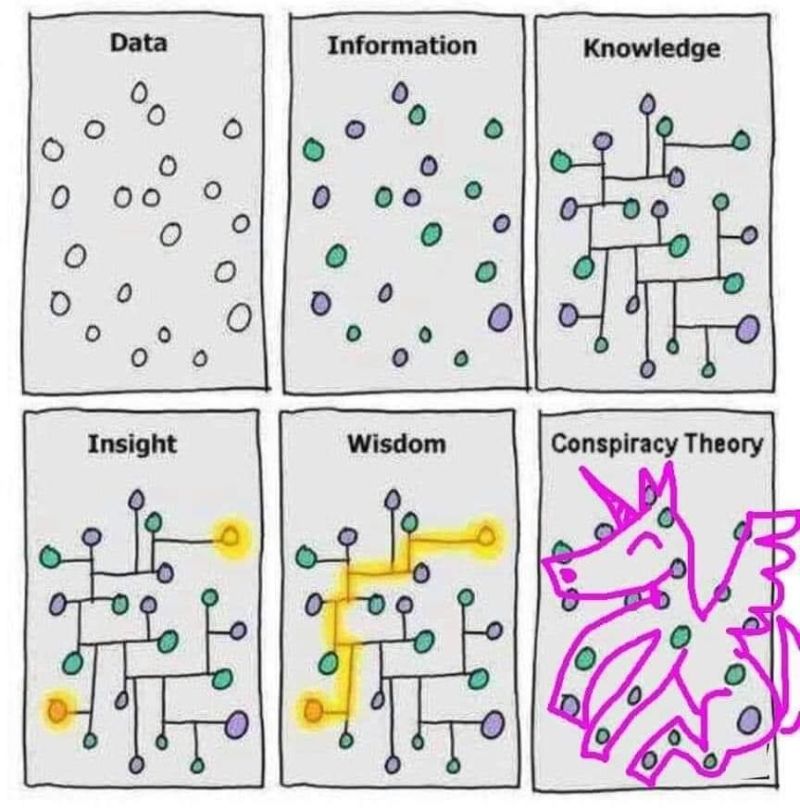

It is important to think carefully about the use and interpretation of digital systems and how data is offered. The interpretation of information depends on the environment in which it is used. Incomplete information can also lead to misinterpretation with all its consequences.

Data, information, knowledge, insight and wisdom can be turned into conspiracy theories through misinformation and misinterpretation.

Too much information in a screen is no longer clear and leads to ignorance or no longer arrives at the recipient. Does the receiver understand what the sender meant? Can the interpretation be explained? Who is ultimately responsible for the information? The quality of information is determined by the input: rubbish in = rubbish out. People still play a crucial role in this.

The digital transformation will only work if we start sharing data with each other and it doesn’t linger behind walls of competitiveness and fear of theft. There are plenty of ways to ensure that competition or privacy is not affected.

For example, if we use and interpret data and information properly, approximate design data is no longer necessary as it can be calculated in detail with computers. This gives us a much more accurate “feel” for design. Games also teach the “feeling” that students have with the problems and formulas rather than the focus on learning calculations.

In this issue, we highlight a number of digital transformation projects in the maritime sector. The attached list of terms described is far from complete and not unambiguous; many applications fall within multiple concepts and applications overlap.

For the time being, we have not yet finished discussing this subject and it will be discussed more often in SWZ|Maritime in the coming years. Do you have any interesting developments to share with your colleagues in this area? Please let us know via swz.rotterdam@knvts.nl and/or mail@nnelinde.nl.

Terms

- Big Data: devices, systems and ships are increasingly equipped with sensors and people and companies are storing more and more information. This creates a reservoir of data. By analysing this data, we can learn and anticipate. It is important to place the data in the right perspective and context, because otherwise it will lead a life of its own.

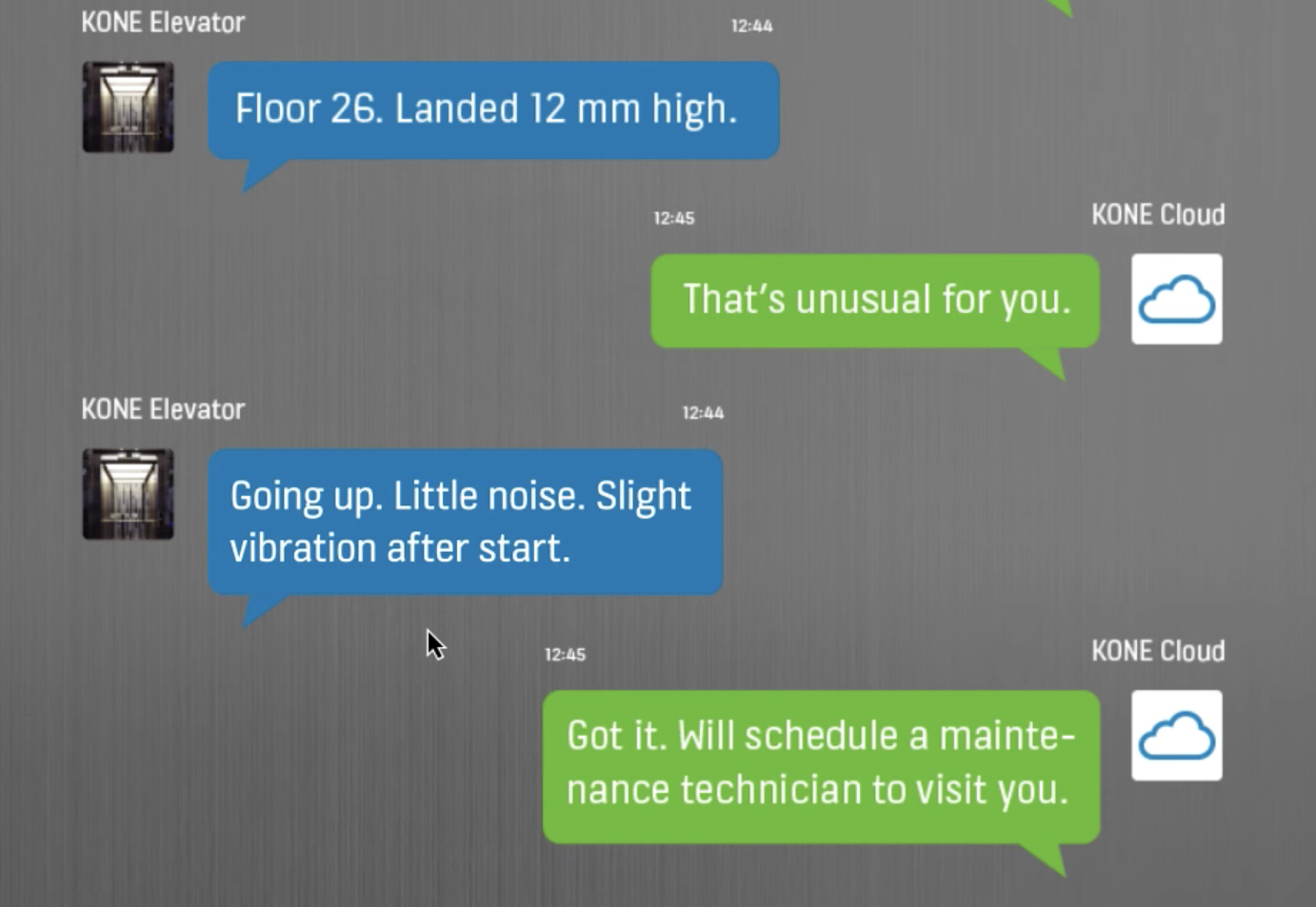

- Internet of Things: data generated by devices and sensors are shared with other devices, a human being does not need to be involved. This creates a network and communication system between “things”: the Internet of Things. A good example of this can be seen in the video below of Kone lifts, in which lifts and their maintenance systems “talk” to each other.

- Digital Twin: a digital twin is a digital copy of, for example, a ship, in which all sensor data and information from the ship’s control systems is used to remotely monitor and possibly control the ship. In a concept phase, the digital twin can also be used for the (operational) design of a ship and in the use phase it can be used for training purposes, both in terms of maintenance as well as use and analysis of operational deployment.

- Blockchain: with Blockchain, the (meta)data about an item, for example the route of a container, a batch of food or a bank transfer, are stored in a “block”. This data cannot be deleted and the block is always supplemented with new data, so that the route of the item can be followed. Data can only be added if the suppliers of the data to be added have been authorised by the block itself. Trials have been carried out in several major ports to use this technology for container tracing systems, the processing of the required cargo documents and financial handling, which can then be carried out completely paperless within a familiar and safe environment.

- Virtual reality: in virtual reality, an environment is simulated in which a human player can practice with a (simulated) practical situation, such as a pilot in a flight simulator. In Constructive simulations, both the human (artificial intelligence) and the environment are simulated. Think for example of a wargame for mission planning or the strategic game SimCity. In the maritime sector, it is used for staff training or, for example, a game about ship stability such as at the Willem Barentsz Maritime Institute.

- Augmented reality: augmented reality (AR) is a live, direct or indirect image of reality to which data can be added by a computer. This is often sensor data or extra information about the surroundings. The user wears glasses and sees information about the objects he is looking at. The technology tries to ensure that the user gets a better understanding of reality by offering that information at the right time.

- Haptonomic feedback: in addition to AR, a system can also provide feedback on physical reality so that the user can feel what is happening. An example of this is that the operator of a dredging arm receives feedback via the joystick on the movements of the arm on the seabed, so he feels how hard or soft the seabed is.

- Artificial intelligence (AI): During the NMTcafé on the Digital Transformation on 3 September, the following definition of AI was put forward: ‘The ability of a system to correctly interpret external data, to learn from this data and to use these lessons to achieve specific goals and tasks through flexible adaptation.’ This means that machines and computers take over people’s thinking by learning from the data offered and carrying out tasks. An example of this is used to control the Ventifoil from Conoship, where the position of the Ventifoil in relation to the current wind direction is used to control the Ventifoil. The eConowind unit then actually replaces the sailor.

- Robotics and autonomous vehicles: by incorporating AI in a machine, physical tasks can also be carried out by robots or vehicles can be equipped with “brains” enabling them to operate autonomously.

- 3D printing: virtual data can be used not only to learn from and control machines, but also to create new components via 3D printing. An example of this is 3D printing of a ship’s propeller.

Picture (top): A service engineer sees information about the objects he is looking at via augmented reality glasses (photo Anthony Veder).

Unfortunately, we experienced some technical difficulty in printing this article in our paper issue. Because of this, some of the figures on pages 17/18 were not displayed correctly. In this online version, this has been remedied.