Ulstein’s has presented its second hydrogen hybrid design for the offshore wind industry, the Ulstein J102. It can operate in zero emission mode 75 per cent of the time using readily available technology. ‘We have designed a jack-up that can keep up with the energy transition,’ says Nick Wessels Marketing & Sales Manager at Ulstein Design and Solutions.

‘We have carefully analysed the operational cycle of wind turbine installation vessels (WTIVs) and looked at the power demand in the various modes of operations,’ says Ko Stroo, Product Manager at Ulstein. ‘This analysis showed that circa 75 per cent of its time, a WTIV is in jacked-up position performing crane operations. Using a combination of a hydrogen fuel cell system and a relatively small battery energy storage system (BESS) is then sufficient to meet the overall power demand on board and crane peak loads.’

This means that 75 per cent of the time, the hydrogen hybrid jack-up will be able to operate emissions free. The technology for this is available today. The remaining 25 per cent it operates on a diesel-electric installation. ‘You see, everyone is talking about the future and making ships hydrogen-prepared, but we have focussed on what can already be achieved with the technology that is already there,’ says Wessels. ‘That is why last year we started with an existing design of ours, a construction support ship, to see how far we could get in zero-emission mode with already existing technology.’

Wessels continues: ‘The main problem is that there is no bunkering infrastructure for hydrogen. Yet, if you look at the technology that is available: you can get hydrogen tanks containerised, fuel cells are already there in sufficiently large power ranges, you can just develop a ship that can operate fully on hydrogen, albeit for a limited time.’

The length of time a ship can operate this way is now mainly determined by the storage technology, explains Wessels. ‘The hydrogen is now stored in a pressurised gaseous form (500 bar). However, once you can store it as a liquid, you get ca. 3 times more energy from a similar size tank/container. Then we arrive at a ship that you can operate completely emissions free in DP mode for 13-14 days.’

From containerised to tanks

‘We opted for a containerised solution because you can simply place it on and remove it from the ship with its own crane. The containers can be brought to the ship by truck. Those containers are already road-certified. Then such a ship can be used all over the world. You still have a diesel-electric plant on board, but you can choose to operate part of the time in zero-emission mode, for example during installation work or when you are in a port area,’ Wessels states.

‘As soon as the bunkering infrastructure becomes available, you can use the space where the containers are currently located for tanks. And those tanks can handle 2x 300 m3 of hydrogen and then you can just sail in DP mode on hydrogen for a month. What you then have is a vessel that can keep up with the energy transition. This will prevent the technology from catching up with you in five years’ time. That is what people are all afraid of now. We have simply made a design in which hydrogen and fuel cells are already present and have now applied this same technology to a jack-up.’

Using readily available technology, the additional cost for the jack-up is said to be limited to less than 5 per cent of the total CAPEX.

Do what is possible now

‘We can now see that jack-ups to be built are hydrogen-prepared, but they do not say how. But we do notice that they seem to be equipped with very large battery systems,’ Wessels continues. Batteries are not necessarily the most economical power technology on board. Battery charging will be partly by clever energy regeneration from crane operation or from shore power, but probably quite some will come from the diesel engines on board. In addition, batteries are just very heavy. This is not beneficial for a jack-up, because you have to lift all that weight out of the water, according to Wessels. For a WTIV design, weight savings are essential for minimising Elevated Weight and optimising the Variable Deck Load.

Wessels does not think that hydrogen is an immediate solution for all types of ships. ‘I do not think that hydrogen will apply to a large ocean liner, for example. In any case, I do not see that happening in the shorter term. What we focus on is on ships that are regularly in port. You can already take the first steps towards zero-emission operations. One can wait for technology to be matured, but technology is never perfect. And, of course, you can have a vision of the future, and that vision is necessary, but people sometimes forget what is already possible today.’

Features of the hydrogen hybrid J102

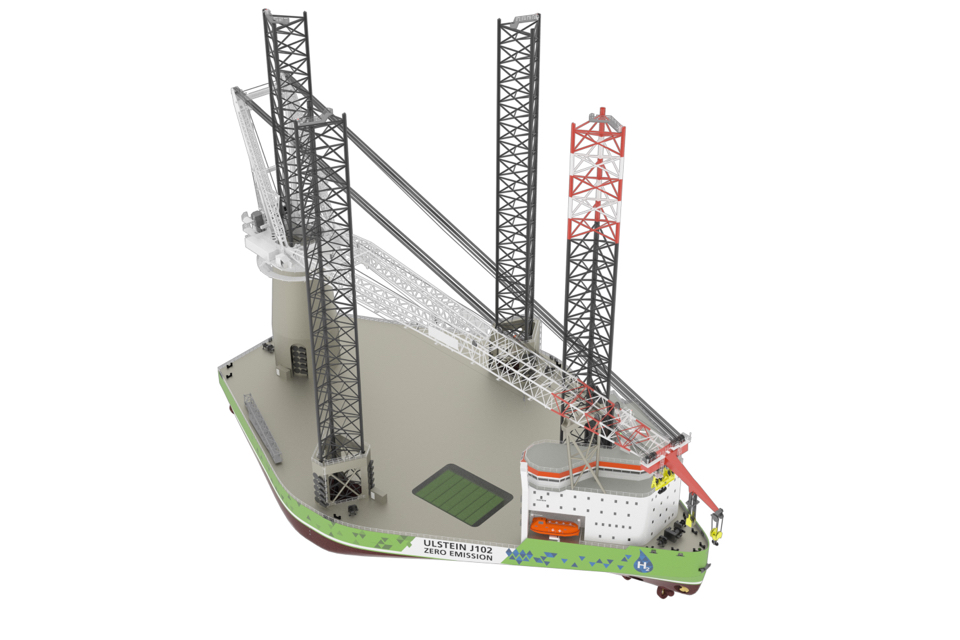

To remind what the Ulstein X-Jack design entails: Ulstein started designing jack-ups about 4 years ago, starting from scratch. ‘And that is sometimes an advantage,’ says Wessels. ‘Ulstein came up with a design that is more balanced and lighter than a conventional design with the same capabilities.’

The J102 is the second largest unit in the X-Jack series and measures 142 metres long and 87 metres wide and has a 2500-tonne crane. It features a kite-shaped hull allowing for large leg spacings. The main crane is installed around the stern leg on centreline. The patented lay-out with a simple cruciform primary structure achieves a 15 per cent steel weight reduction compared to other jack-ups of similar capacities.

Positioning the legs widely apart in a square pattern results in efficient use of available deck space, at the same time effectively counteracting the crane overturning moments. This set-up also creates more body around the legs, enabling the use of large spud cans to reduce loads on the seabed. It is capable of jacking in 3-metre waves (Hs).

‘There is space on board for 4 turbines of 17 MW or 5 of 12 MW, such as the Haliade-X. The larger version of this jack-up (J103) could also be equipped with a 5000-tonne crane, but of course there must be demand for it,’ adds Wessels.

CO2 reduction of the hydrogen hybrid is said to amount to 4000 metric tonnes per year. The emission reduction per installation cycle amounts to 25 per cent. The H2 fuel cell system consists of a PEM fuel cell. Compressed H2 is stored in 7 40ft containers and the ship is equipped with battery energy storage.