Recently, the Blue Nodules project in which Royal IHC was the coordinating partner has ended. The deepsea mining research project has resulted in a prototype vehicle for nodule collection, the testing of many components and sought ways to minimise a range of environmental issues.

Polymetallic nodules are potato shaped rocks that can be found on the ocean floor. They contain nickel, cobalt, copper and manganese and could therefore be an important raw material. Blue Nodules was a research and innovation project to develop a highly-automated and technologically sustainable deepsea mining system for harvesting these nodules from the sea floor, with minimum environmental impact. With the conclusion of the project, the results have now been made public.

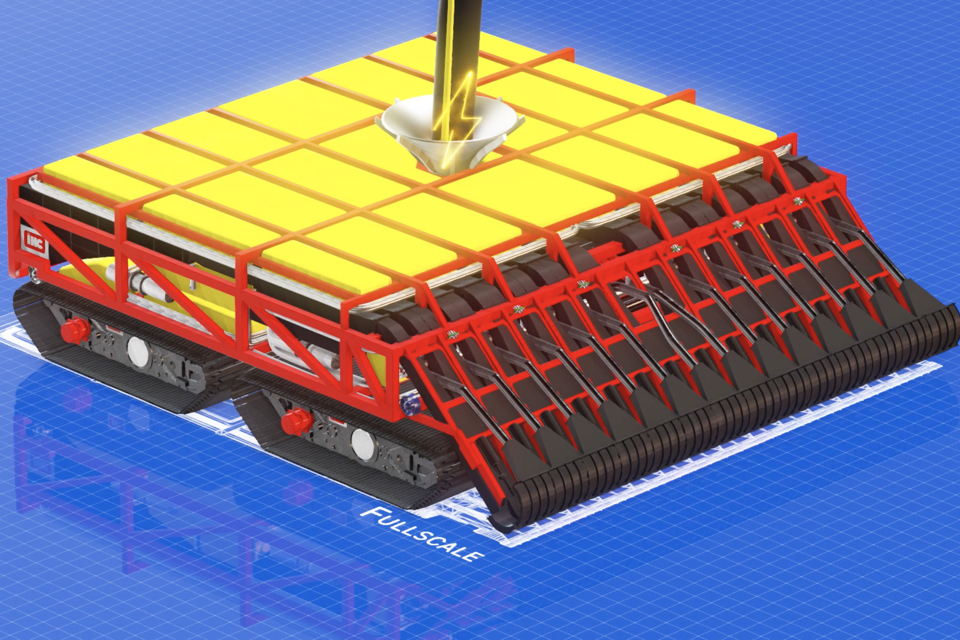

IHC has developed the seafloor nodule collector Apollo II. The vehicle has four tracks increasing manoeuvrability, efficiency and reducing the sediment plume. To limit its weight, it is made of lightweight materials. It is electrically powered to make it as energy efficient as possible. A jet collector to pick up the nodules was also developed. The 16-metre wide full-scale vehicle will have all the basic features of the Apollo II including being all electric and the four-track layout.

To lower the vehicle to the seafloor 5 kilometers below the surface, it is connected to an umbilical which provides power and communication signals. It is also connected to a vertical transport system or riser pipe that will transfer the ore from the seabed to the surface operation vessel. The collector will be able to harvest 400 tonnes of nodules per hour from a mined area of 0.03 km2.

Research into plumes

Water jets blast nodules free from the soft muds in which they lie, but this also creates clouds of unwanted sediment that are sucked up to and released as a plume behind the vehicle. Small animals living in the sediment and attached to the nodules will be removed during mining operations. Recolonisation may take a very long time.

That is why a new method was designed to separate the nodules from the sediment inside the collector. Using an inclined tube in which nodules slide to the bottom. The sediment is ejected at the top of the tube passing to the rear of the collector where it is released. This mostly deposits on the seabed behind the collector, but some remains suspended in the water forming a sediment plume that is carried away from the mining site where it may affect the seabed fauna.

A computer model was created to help predict how far the plumes would spread. The results show the coarse of sediment grains settle within several kilometres of the mining site. However, the finest grains are transported over much greater distances. It was researched whether compaction of the seabed by the collector would hinder recovery of life within the sediments and concluded that other factors, such as deposition of the sediment plume behind the vehicle would be more important.

It was also found that the sediment not removed and which is therefore pumped up to the vessel above water, is best released as close to the seabed as possible. At other depths, it may impact the animals living there.

Underwater noise

The programme also looked into the possible impact of noise from the collector, pumps and surface vessel. One of the conclusions was that the pumps should not be located in the SOFAR channel (short for Sound Fixing and Ranging channel), about one kilometre below the sea surface. As sound can transmit over long distances here and this channel may be used for communication by whales.

Once above water, the nodules are de-wetted and stored on the vessel until they can be loaded onto bulk carriers. Transfer options were also investigated. The nodules can either be re-watered and pumped onto the bulk carrier where they are de-watered again or transferred in dry state using a conveyor belt. The latter option means the ships need to be close together.

In order to share the results with the public the consortium has created a movie, which you can watch below.

[newsletter_form title=”Would you like to receive the free newsletter of SWZ|Maritime? Please fill in your e-mail address here:”]