The structural assessment process required for heavy-lift transport projects on board multi-purpose vessels can benefit from existing finite element (FE) models according to DNV GL. This reduces time spent on FE modelling and analysis while at the same time increasing the quality of the results.

Structural simulation models generated during the design phase of a vessel can and should be reused throughout the operational lifetime of the ship, for example when performing structural assessments for heavy-lift projects. Doing so not only enables a more sophisticated approach to technical assessments, but also significantly reduces the cost of modelling and generating load cases.

Classification society DNV GL states that in recent years, the multi-purpose vessel segment has seen a growing trend towards individualised transport jobs in the heavy-lift and project cargo businesses, with the items carried growing in size and weight. This development in turn has been driven by a general tendency to minimise the scope of on-site final assembly work to mitigate the associated economic and quality risks.

‘Ensuring the structural integrity and safety of the cargo as well as the ship itself are core concerns for the shipper, the vessel owner and operator, and their underwriters,’ Dr Olaf Doerk, Head of Advisory West Europe at DNV GL – Maritime, explains. ‘Project-specific strength assessments focusing on proper sea-fastening as well as the structural integrity of the vessel and its cargo are therefore standard procedure in heavy-lift projects. In many cases however, the lack of a suitable structural finite elements (FE) model for the strength assessment is a bottleneck which can cause delays and additional costs.’

3D FE models improve structural assessments

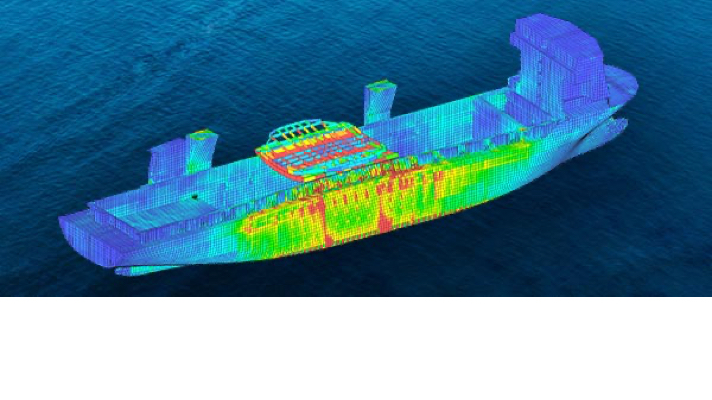

Considering the variety of heavy-lift and project cargo jobs, a global 3D FE model of the entire vessel offers the greatest flexibility and coverage for structural assessment, says DNV GL. Traditional global FE models with web frame spacing as a typical element size do not provide the required level of detail and structural resolution, especially when assessing the double-bottom area.

A modelling approach initially developed in a joint development project by DNV GL and major industry partners, called Advanced Whole Ship Analysis (AWSA), can help overcome this issue. AWSA combines global strength and cargo hold analysis based on fine mesh, that is, frame spacing as a typical element size, with global FE models. ‘Reusing these fine-mesh global structural FE models from the design phase for strength assessment calculations in heavy-lift projects during the operations phase is a very cost-efficient – if technically sophisticated – approach,’ says Doerk. ‘Its flexibility makes it suitable for a wide range of applications, from simple double-bottom checks through to full-scale global strength analyses accounting for specific loading and sailing conditions.’

Depending on the given organisation, the available capabilities, and the required scope or level of analysis, strength assessments for heavy-lift cargo projects may be carried out either by the owner or operator of the vessel, or with support from the classification society. Development work on the AWSA-based life cycle approach continues, but the method is already being streamlined and has been proven to be a viable solution. Key items on the agenda include the question of ownership of various structural models, integration of the as-built status, and enabling fast and efficient load generation.

Intermarine business case

When Intermarine was considering carrying an extremely heavy load on the deck of one of their heavy-lift vessels, the engineers had to quickly do a quite complex structural analysis to check whether such an unusually heavy cargo unit could be carried without compromising the safety of the ship or the cargo itself.

‘We made use of an existing FE model of one of our heavy-lift vessels, whose files from the newbuilding phase had been stored by DNV GL’s advisory unit. This enabled us to carry out the strength assessment of the cargo hold area with different reinforcement options in an efficient way,’ says Frank Fischer, Managing Director of Intermarine. ‘Experts from DNV GL’s advisory section conducted the demanding analysis in close dialogue with our cargo engineers. Based on the solution found, we could apply for a unique cargo transport job with confidence on safety.’