SAL Heavy Lift and Mammoet have transported a massive 955-tonne pressure vessel from Belgium to Russia. Manufacturer Coek Engineering spent two years on the construction of the component, which comes with a 10 million euros price tag.

The pressure vessel is coated with titanium on the inside and will be used by Russian gold miner Polymetal to extract gold from ore under high pressure and temperature. It took more than 30,000 man-hours to build the 50-metre long colossus.

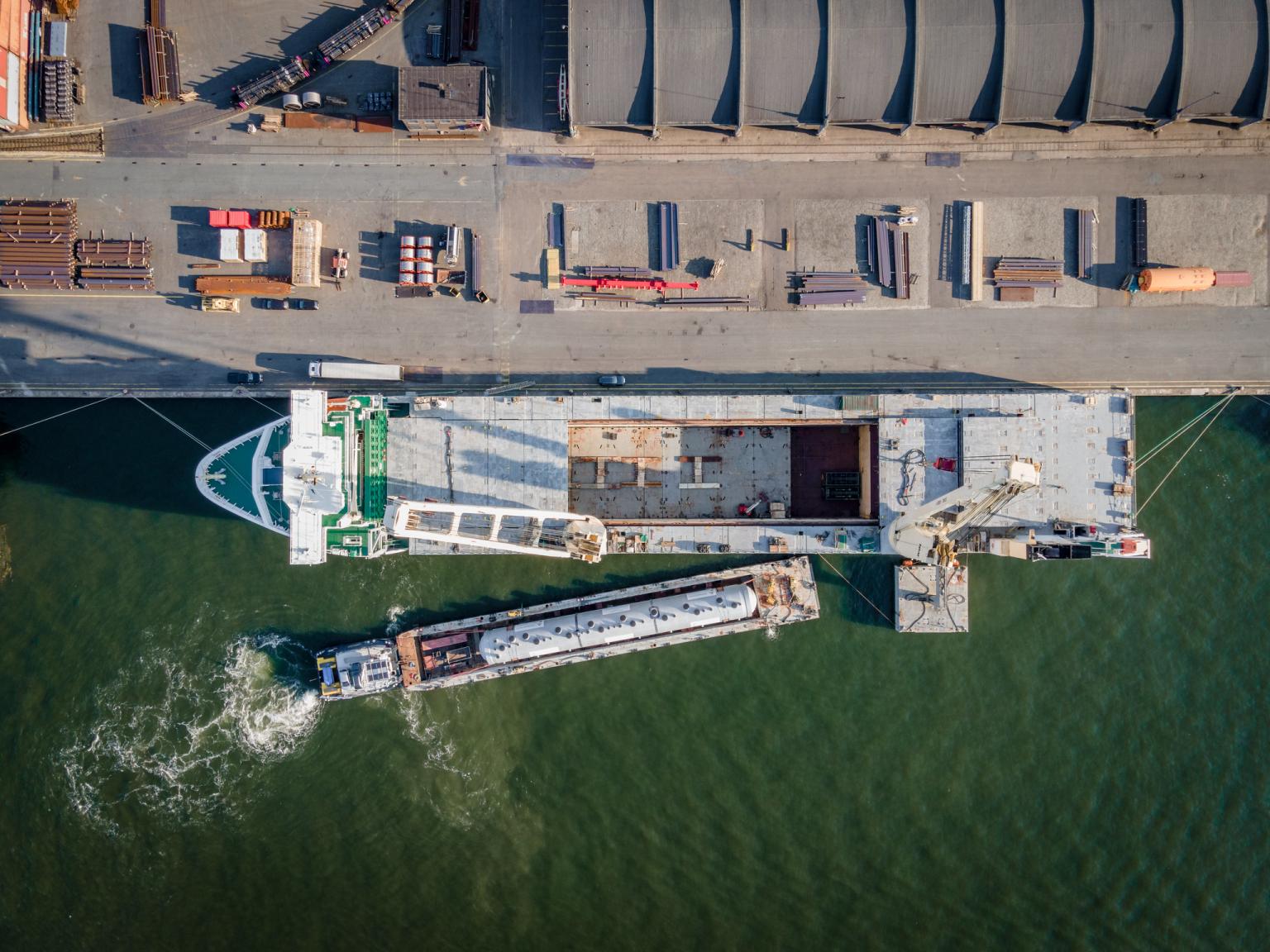

Mammoet was contracted to move the pressure vessel from Coek Engineering’s manufacturing facility in the Belgian village of Geel to the Albert Canal, where it was put on a barge to Antwerp. In Antwerp, the cargo was lifted onto the MV Svenja of SAL Heavy Lift. It is being shipped to the port of De Kastri in Eastern Russia, from where the cargo will travel across the Amur River to its final destination, Amursk.

What makes the transport challenging is that the Amur river is only navigable for heavy transports for a small part of the year. The water level strongly fluctuates and from the second half of August, the risk of low water increases sharply. ‘If our production had been delayed and the pressure vessel could not have been shipped this month, it would have had to be stored here for another year,’ says Coek Group’s chairman Ilse Vanlommel. The trip will take a total of fifty days to complete.

Photos: SAL Heavy Lift and Coek Engineering

This article first appeared on Project Cargo Journal, which is another publication of SWZ|Maritime’s publishing partner Promedia.