While the Dutch are struggling to decide on four new submarines, the Japanese ordered no less than 22. So far, Japan has eleven of these in operation. The last of which is the first Japanese submarine equipped with lithium-ion batteries and without Stirling engines. An example to be followed?

Nowhere has the demand for submarines increased so dramatically as around the Pacific. This certainly has to do with the expansion and modernisation of the Chinese, Russian and North Korean fleet, in which the submarine plays an important role. China, for instance, has an underwater fleet of around seventy submarines.

A submarine is a weapon system specially designed to secretly survey or spy potential enemy targets and is able to attack submarines and surface vessels by torpedoes or missiles undetected. Some are even able to launch nuclear missiles. To counter this threat Australia, Japan, Vietnam and other countries in the Pacific are procuring or constructing more submarines.

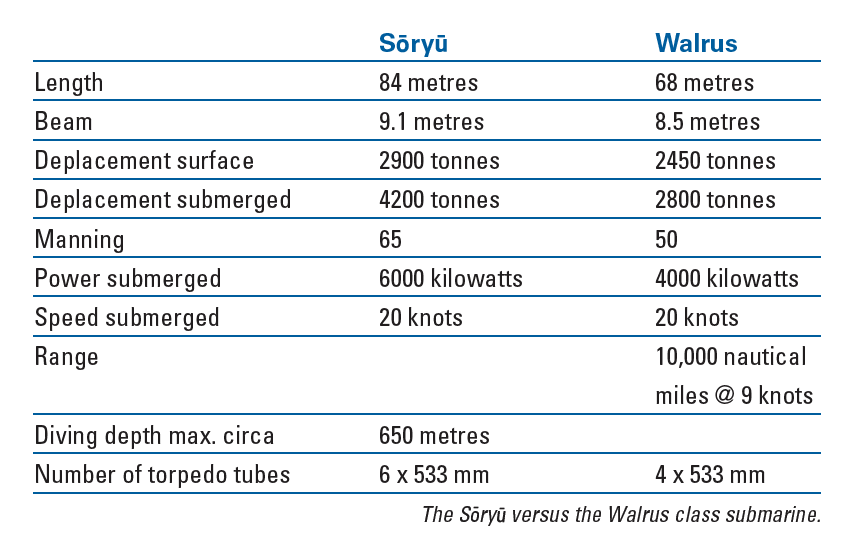

The Japanese submarine class Soryu is an impressive product of cooperation between Mitsubishi Heavy Industry and Kawasaki. Construction of what is one of the largest diesel-electric submarines of its kind, started in 2005 and the first was commissioned in 2009. So far, Japan has eleven Soryu-class submarines in operation. To get an impression of the dimensions, the Soryu is compared with the Dutch Walrus-class submarine, see the table.

Hydrodynamically Shaped Hull with X Rudders

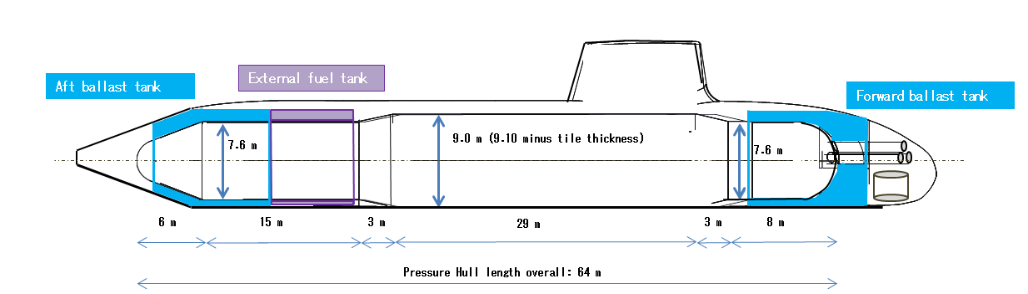

The submarines have a pressure hull and a hydrodynamically shaped hull around it. The pressure hull consists of exact circular frames made of high yield strength steel to withstand the high pressure and is subdivided in watertight compartments. The forward and aft ballast tank and a fuel tank are located outside the pressure hull.

Both submarines have computer aided X rudders instead of the more conventional plus (+) rudder arrangement. This X configuration provides among other things high manoeuvrability, especially close to the seabed (and in case of damage to one of the rudders, better escape options). This X rudder configuration was initially developed by Kockums for the Swedish Gotland-class. In order to reduce manning, a high degree of automation has been applied.

These submarines have X rudders instead of the more conventional plus arrangement

Silent Operation

The most important feature of the submarine is listening and not being heard (or seen while snorting and sailing just below the surface). The vessel needs to be able to locate a target at a greater distance and not produce any sound itself. To this end, this submarine has an extensive sonar suite consisting of a bow array, flank array and towed array sonar. With these towed sonar systems, a target can be detected up to seventy kilometres away.

For observations at the water surface, the boat is equipped with an optronic mast and a radar system.

On the other hand, there must be very strict noise requirements on flow and machinery noise. Reduction of flow noise is achieved by a suitable hydrodynamic hull form and not to forget a non-cavitating low noise propeller. Apparently, the Japanese submarine is equipped with a seven blade propeller.

All noise-producing systems are provided with acoustic isolation

Research is already being carried out into pump-jet propellers (with thirteen blades) for the following class of submarines and it is expected that these will be remarkably quieter. The Dutch Maritime Research Institute (Marin) in Wageningen performed extensive and long-term research into these types of propellers.

To prevent machinery noise, all noise-producing systems are provided with acoustic isolation, sound-damping supports and every pipe system has bellows. These are probably combined with floating decks as well.

The Soryu is equipped with anechoic tiles, which ensure that the sonar signals of the opponent are hardly or not reflected, reducing the chance of detection. Similar tiles were already applied in the Second World War. To increase survivability, a large number of measures has been taken as in every submarine design. An important requirement is to enhance the shock resistance of the boat to a very high level including all its systems, infrastructure, pipelines and valves, and so on.

The Soryu submarine’s pressure hull.

Stirling Engines

The Soryu has two Kawasaki twelve-volt 25/25 SB-type diesel engines and four Kawasaki Kockums V4-275R Stirling engines. They provide a total power output of 2900 kilowatts surfaced and 6000 kilowatts submerged. The electric propulsion motor drives a propeller through a single shaft.

The Soryu is the first Japanese submarine to be equipped with Stirling engines as developed by Kockums in Sweden. Stirling is a silent and vibration-free external combustion engine. This air-independent propulsion system reduces the need for frequent battery charging and increases the submerged endurance of the submarine, which is obviously an important feature of a submarine.

Lithium-ion Batteries?

The first ten submarines are equipped with traditional lead acid batteries in combination with the Stirling motor. The eleventh Soryu, however, is the first Japanese submarine equipped with ruggedised lithium-ion batteries, without the Stirling engines.

Lithium-ion batteries indeed have substantially more electric storage capacity than lead-acid batteries [1]. These lithium-ion batteries have been placed in the existing battery storage areas as well as in the spaces previously occupied by the AIP Sterling engines. In this way, the submarine could be equipped with a large amount of more powerful batteries. This has improved underwater endurance significantly and will further reduce the already low underwater noise levels. The financial budget of this eleventh submarine is 536.7 million US dollars, while the costs of number ten amounted to 502 million US dollars according to website Jane’s 360.

Extra Underwater Endurance Not Specified

It is clear that the Japanese navy has strong indication that lithium-ion is the way forward and will compare these batteries to the previous AIP system for operational effectiveness (see Wikipedia Soryu submarine). No concrete information has been made available by the Japanese navy about the expected gain in the so important underwater endurance. They are talking about weeks instead of days, which is obviously depending on the available space to install these batteries with the necessary safety measures.

It is clear that the Japanese navy has strong indication that lithium-ion is the way forward

Example to Be Followed?

Japan is the first country to really install these batteries. Navies are reluctant to apply lithium batteries because of fi re and explosion hazards. Lithium batteries are prone to catching fire. Yet, the Japanese navy must have found a way to make the system safe enough to send to sea and the absence of lead-acid batteries will also reduce some other risks. Japan is not alone in developing new batteries for submarines.

South Korea also plans to install lithium-ion batteries in a new class of submarines that could enter service in the next decade. While the Soryu class of submarines entered service in the Japanese maritime self-defense forces fleet, the next class is already being developed, including further evaluation of high power-density batteries.

The application of lithium-ion batteries appears to be an important step forward in the development of the submarine and may be worth considering when replacing the Walrus class.

This article appeared in SWZ|Maritime’s December Japan Special and was written by Jaap Huisman. Huisman has been involved in naval construction projects in a variety of positions throughout his career with either the Royal Netherlands Navy or the Dutch Ministry of Defence.

This article appeared in SWZ|Maritime’s December Japan Special and was written by Jaap Huisman. Huisman has been involved in naval construction projects in a variety of positions throughout his career with either the Royal Netherlands Navy or the Dutch Ministry of Defence.