Accumulation of dirt in a fire main isolation valve can cause it to start leaking. In a recent Mars Report, this deficiency was found during a port state control inspection and needed to be repaired before the ship could leave the port.

A transcript of the incident as covered by Mars:

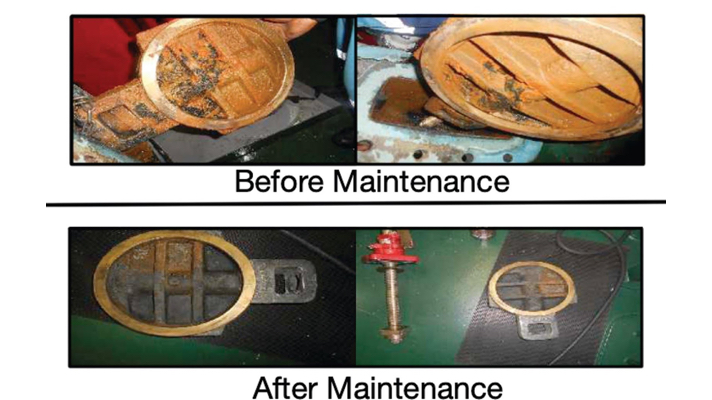

While in port, a vessel was inspected by flag state authorities. They noted a deficiency related to the fire main isolation valve; the valve was leaking. A plan was made to open the valve to verify its condition and a risk assessment was conducted on that plan. The plan included blanking the line at the valve side and keeping the deck line available for firefighting while the maintenance work was underway.

Once opened, scale and dirt were found within the valve. The valve stem and the disc were re-buffed and cleaned and the valve refitted in position. The valve was then pressure tested and found to be holding well. Port state authorities boarded to confirm the valve was repaired and closed the deficiency.

Company Investigation Findings

The company investigation found, among other things:

- The valve position is inverted at an angle for operation, which caused accumulation of scale and dirt in the bonnet of the valve.

Lessons Learned

- Check the functionality of the main fire isolation valve during every fire drill.

- After considering the design and position of the valves the company decided to change the maintenance schedule for this equipment.

- Opening, inspection and overhauling of all fire and foam isolation valves were revised.

Mars Reports

This is one of the May Mars Reports, originally published as Mars 201946, that are part of Report Number 321. A selection of this Report has also been published in SWZ|Maritime’s July/August issue.

More reports are needed to keep the scheme interesting and informative. All reports are read only by the Mars coordinator and are treated in the strictest confidence. To submit a report, please use the Mars report form and send it to mars@nautinst.org.