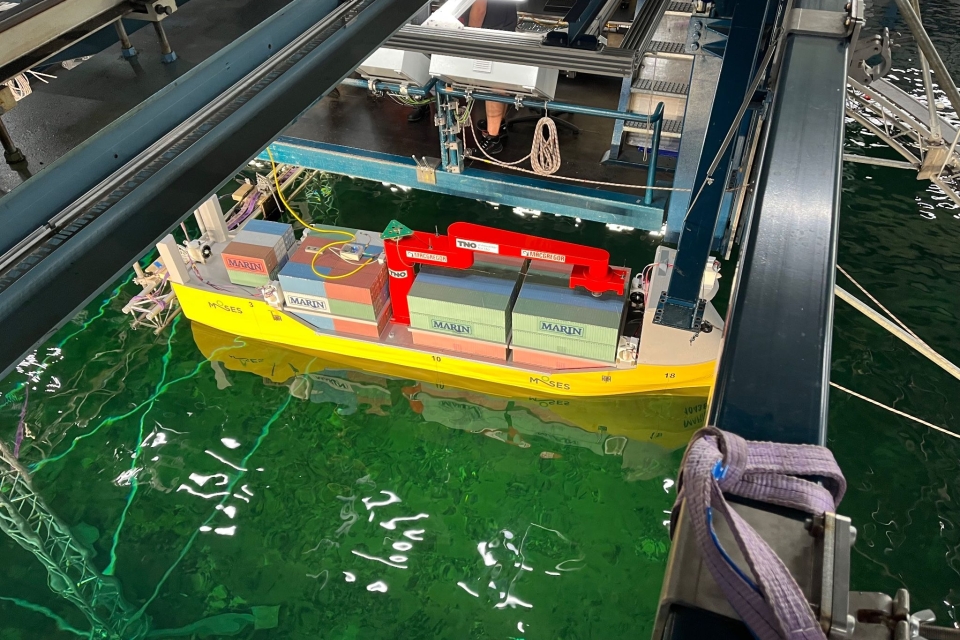

Last week, MARIN held a MOSES pilot demonstration. This involved an autonomously sailing zero-emission container feeder making a roundtrip between two ports in MARIN’s Seakeeping and Manoeuvring Basin.

MOSES (autoMated vessels and supply chain Optimisation for Sustainable short SEa Shipping) is a Horizon 2020 (H2020) funded project, which aims to significantly enhance the short sea shipping component of the European container supply chain by a constellation of innovations.

This includes innovative vessels and the optimisation of logistics operations. In the project, the vulnerabilities and strains that relate to the operation of large container ships are addressed.

The scope of MOSES project will be reached through the implementation of the following innovations:

- For the short sea shipping leg an innovative, hybrid electric feeder vessel (MOSES feeder) that will prevail from different vessel concepts and will be designed to match dominant short sea shipping business cases, increasing the utilisation rate of small ports. The MOSES feeder will be outfitted with a self-sufficient robotic container-handling system that will simplify the (un)loading of containerised cargo at Hub Ports and improve the operational capacity of small ports.

- For deepsea shipping ports the adoption of an autonomous vessel manoeuvring and docking scheme (MOSES AutoDock) that will provide operational independency from the availability of port services. This scheme will be based on the cooperation of (i) a coordinated swarm of autonomous tugboats with (ii) an automated docking system based on an existing product.

- A digital collaboration and matchmaking platform (MOSES platform) that aims to maximise and sustain short sea shipping services in the container supply chain by matching demand and supply of cargo volumes by logistics stakeholders using Machine Learning (ML) and data driven-based analytics.

MOSES will be validated by pilot demonstrations in relevant testing environments. A sustainability framework will be developed within the project for evaluating the performance and viability of the proposed innovations. This evaluation will also lead to concrete policy recommendations regarding short sea shipping in Europe.

Also read: ProZero joins EU funded automated shortsea vessel project

AutoDock pilot

Pilot demonstrations in relevant testing environments, supported by concrete business cases, are to validate MOSES. In total there will be three pilot demonstrations.

The first is named AutoDock, which will showcase the automated manoeuvring, docking, and mooring scheme for large ports proposed by MOSES. This is achieved by demonstrating the way that a swarm of autonomous tugboats may intelligently cooperate to manoeuvre a large container ship and direct it into an available berth at the port and the way that tugboats may collaborate with an automated mooring system that will efficiently complete the process.

The model testing physical scenario will be conducted according to the local environmental conditions prevailing at the time of the demonstration. In addition, the demonstration aims at appropriately addressing a wide range of operational scenarios to simulate a use case as realistically as possible. AutoDock will be carried out at the physical area surrounding Faaborg harbour in Denmark, where TUCO maintains its facilities.

Yesterday, 18 September, Trelleborg Marine & Infrastructure’s Gen2 AutoMoor unit landed in Faaborg, Denmark, ahead of the pilot demonstration that is to take place this month.

Pilot 2: Innovative Feeder Vessel

The objective of this pilot is to showcase the innovative characteristics of the MOSES feeder vessel by demonstrating its seakeeping and energy performance capabilities. This activity included testing a scaled ship model for one – out of the three total – vessel design conceptualised within MOSES.

The ship models are constructed by MARIN at their facilities and the design properties include service speed, manoeuvring and seakeeping performance in various operational conditions and scenarios. This demo took place on 14 September.

The autonomous operation was carefully investigated and prepared through computer simulations. The onboard dummy of the robotic container handling system was developed by TNO and MacGregor.

Also read: How MARIN verifies Tetrahedron’s new tag line system

Robotic Container Handling System

The third pilot demonstration aims to showcase the (semi)autonomous operation for (un)loading containers from the MOSES innovative feeder with the Robotic Container Handling System that will be developed. This will be accomplished by demonstrating the autonomous container handling capability of the system, the shared control between the human (remote) driver and the robotic crane system.

Intervention options for the remote operator through the remote supervisory Shore Control Station (SCS) will be also demonstrated. This pilot demonstration will be conducted at the MacGregor test facility in Örnsköldsvik (Sweden), where the crane itself will be mounted on the shore (instead of on board a vessel) for cost-efficiency reasons.

MOSES consortium

The MOSES consortium consists of seventeen partners from seven EU countries (Greece, Cyprus, Spain, Italy, the Netherlands, Denmark and Finland). MOSES’ team is composed of system and automation designers (NTUA, MARIN, Astander, CORE, ESI, TNO (Innovation Hub i-Botics), Danaos), maritime logistics and supply chain experts (Seability and Circle), technology platform providers (MacGregor, Trelleborg and TUCO (ProZero)), regulatory organisations (DNV), and stakeholders and end-users (SAT, Fundación Valenciaport, PCT, and MHM).

The project started July 2020 and will run until December 2023. In November, a final event will take place in Brussels, Belgium.

Picture (top): The feeder vessel design in MARIN’s basin (by MOSES).

Also read: VIDEO: MARIN completes testing of new F-series propellers