Researchers at Chalmers University of Technology in Sweden are the first to demonstrate a method that reduces the aerodynamic resistance of ships through the Coanda effect by 7.5 per cent. This opens the way for large cargo ships borne across the oceans by wind alone, as wind-powered ships are more affected by aerodynamic drag than fossil-fuelled ones.

To hit international climate targets, the carbon emissions from shipping must be reduced by more than fifty per cent by 2050 compared to 2008 levels. As much as 99 per cent of global shipping is currently dependent on fossil fuels. Even though electricity may carry smaller ferries across shorter distances, the electrification of larger, longer-haul ships is hampered by range limitations. This means that the need for new energy-efficient propulsion technology solutions for shipping is both major and urgent.

Inspired by an aerodynamic technology used in aviation, the researchers at Chalmers have found a way to reduce a ship’s aerodynamic drag by 7.5 per cent. The result is increased energy efficiency and reduced fuel consumption.

‘For an oil tanker going from Saudi Arabia to Japan, this would mean a reduction in fuel consumption of about ten metric tonnes,’ says Kewei Xu, postdoc researcher in marine technology at the Department of Mechanics and Maritime Sciences at Chalmers. ‘Reducing aerodynamic drag has seldom been examined; our study is one of the first of its kind.’

Also read: The winds of change: One zero-emission dilemma for shipping solved?

Paving the way for wind-powered ships

The unique method is particularly relevant to future wind-powered shipping. Wind-powered propulsion is not a new technology per se; it was dormant for decades, with strong interest in it only resuming in recent years.

A ship with wind-powered propulsion requires a more efficient aerodynamic design, as it does not have the constant, high-power output of a fossil-fuelled ship. Previously, the aerodynamic effect was not deemed important compared to a ship’s total resistance in water. But when it comes to wind-powered propulsion, the researchers’ method could open up new possibilities.

‘In the next few years, we will probably see ships combining wind and fuel-powered propulsion. But our long-term aim is to make wind power the sole energy source for cargo ships and the like,’ says Xu.

Also read: ONE orders containerised wind-assist units from Econowind

Coanda effect makes airflow attach to curved surfaces

Central to the method is the steady flow Coanda effect. This is based on the tendency of a fluid to flow – like water down the back of a spoon – along an outwardly curved surface (convex), instead of launching away from it.

The Coanda effect is named after Romanian inventor Henri Coanda who, around 1910, was the first to recognise the practical applications of the phenomenon in aircraft design. Today, the effect is used in jet aircraft, where aerodynamic lift is increased as the jet stream “sticks” to the wing. The Coanda effect affects air and liquid flows in many different contexts, such as air conditioning.

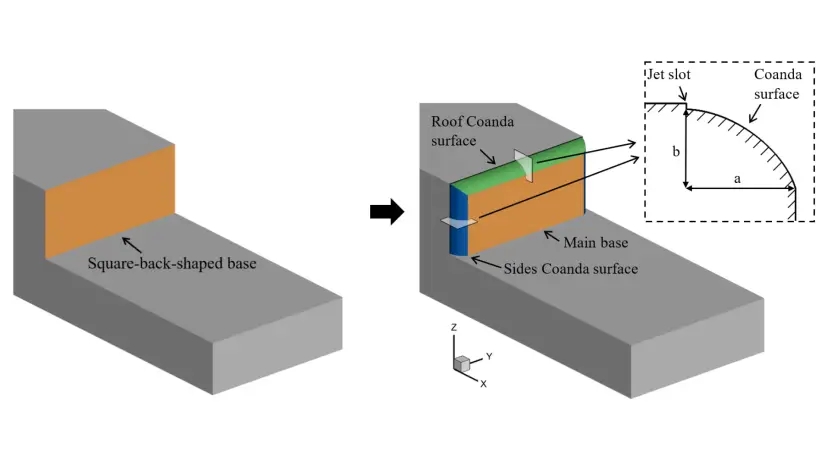

In shipping, one of the main sources of aerodynamic drag is the square-shaped back of the ship’s superstructure; the part that emerges from the deck. The new method developed by the Chalmers researchers induces the Coanda effect around this area.

‘By creating a design with convex edges on the ship’s superstructure and allowing highly compressed air to flow through “jet slots”, the Coanda effect allows air pressure on the ship’s hull to balance out. This, in turn, reduces aerodynamic drag considerably, making the ship more energy-efficient,’ explains Xu.

The method, which can be used on existing as well as newly-designed ships, is described in the researchers’ study “Large eddy simulation of ship airflow control with steady Coanda effect” published in Physics of Fluids.

‘By showing that our method can reduce aerodynamic resistance by 7.5 per cent, we hope the shipping industry will welcome this solution as part of its necessary transition to lower emissions,’ says Kewei Xu. ‘Our study also indicates great potential for reducing drag even more through further optimisation.’

Also read: Sailing short sea liner service EcoClipper on maiden voyage

Safer for helicopters

The Chalmers researchers’ new method would also enable safer take-offs and landings on ships for helicopters.

Turbulence usually arises as air flows down from the ship’s superstructure, destabilising the helicopter. Since pilots need to land or take off on a very precise location on the ship, this comes with major risks and some helicopters do crash. Currently, fences or an adapted shape on the ship are used to minimise risks, but they are not very effective.

The new method dampens the turbulence, as it affects the wind flowing down behind the superstructure. Thus, it would reduce the accident risk for helicopters.

About the research

The numerical tests were carried out on a model ship using high-fidelity CFD (computational fluid dynamics) simulation. The researchers designed the technology, including geometry and jet-blowing intensity. The tests were performed at SNIC (the Swedish National Infrastructure for Computing) in the National Supercomputer Center (NSC).

Picture (top): Ferry Berlin with rotor sail (by Borispugo, Wikimedia Commons).

Also read: How methanol kits for diesel engines allow for quick conversions