While intermittent cycling is commonly employed for a safe recovery process of a rescue boat, it may in fact cause power to exceed design and duty ratings of the electrical components. The Nautical Institute gives this warning in its latest Mars Report.

The Nautical Institute gathers reports of maritime accidents and near-misses. It then publishes these so-called Mars Reports (anonymously) to prevent other accidents from happening. A summary of this incident:

A rescue boat was being recovered after normal deployment and maintenance. At one point, the davit operator tried to stop the raising operation, but the hoist button, emergency stop and limit switch circuits all failed to stop the winch from hoisting. Thankfully, personnel were able to disconnect the electrical power via the 480V main breaker before the boat contacted the davit, avoiding serious damages and injury to personnel.

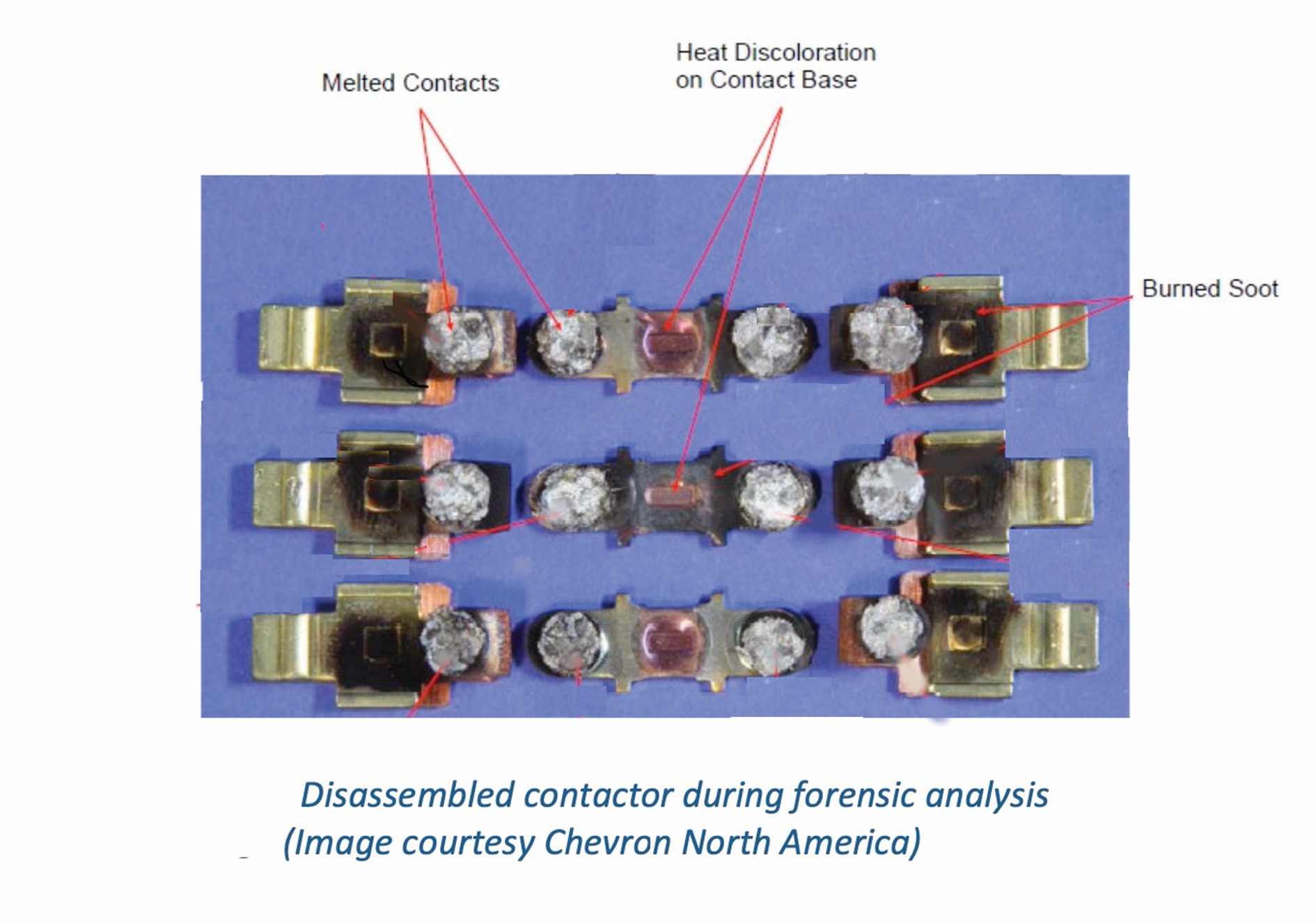

Metallurgical analysis carried out after the event found that the failure occurred when the winch control contactors fused together due to the duty rating being exceeded. Additionally, it appears that the contactors were not rated for intermittent cycling (repeated start/stop sequences) of the winch. After inspection on other installations, several contactors showed evidence of overheating and indications of welded and scorched contacts were found.

Also read: LR machine learning tech reveals that main cause of lifeboat accidents is failing equipment

Intermittent cycling is a common practice during recovery of a lifeboat or rescue boat into the stowed position. For example, a winch may be cycled after the boat has cleared the water to verify release gear condition. Or again, it may be cycled as the boat approaches the davit guides/stops to reduce momentum. While intermittent cycling is commonly employed for a safe recovery process, it may in fact cause power to exceed design and duty ratings of the electrical components.

Advice from The Nautical Institute

- Verify the condition of winch motor contactors and replace any contactors that show signs of excessive wear, overheating, or welding.

- Check the duty cycle ratings of lifeboat and rescue boat davit electrical components and compare those ratings to recommended and commonly-practised boat recovery procedures/processes.

- Confirm the design of the davit safety devices (ie, E-stop and limit switches) to see if they will secure electrical power to the motor in the event of welded contacts.

- Implement training for all personnel that operate the davits to ensure awareness related to electrical duty cycles and the actions needed to isolate power in the event of a welded winch motor contactor.

Also read: Defective tightening nut makes lifeboat launch impossible

Mars Reports

This accident was covered in the Mars Reports, originally published as Mars 202225, that are part of Report Number 356. A selection of this Report will also be published in SWZ|Maritime’s July-August 2022 issue. The Nautical Institute compiles these reports to help prevent maritime accidents. That is why they are also published on SWZ|Maritime’s website.

More reports are needed to keep the scheme interesting and informative. All reports are read only by the Mars coordinator and are treated in the strictest confidence. To submit a report, please use the Mars report form.