Huisman has been awarded a contract from Cosco Shipping Offshore for the design and construction of two >2000-mt Leg Encircling Cranes. The cranes will be installed on the two newbuild X-class wind turbine installation vessels of Cadeler. The ships are expected to be among the largest on the market and will be capable of installing 20+MW wind turbines.

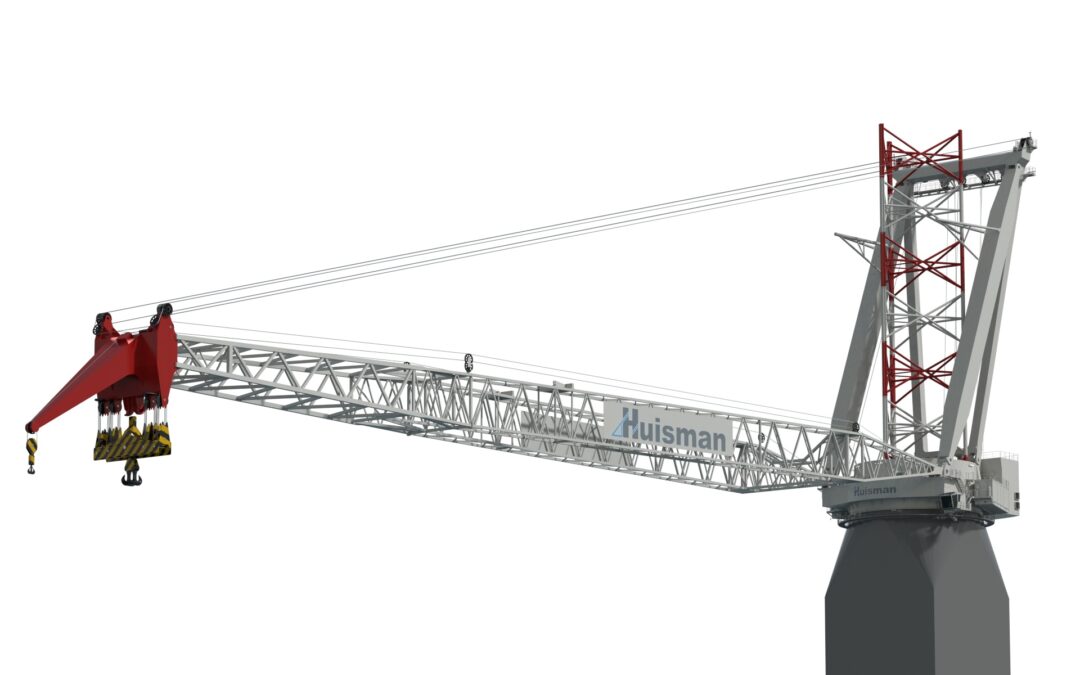

The identical Leg Encircling Cranes have a 155-metre long boom, capable of reaching 180.5 metres above deck. Optionally, the boom can be upgraded to 175 metres in order to increase the lifting height to 200.5 metres. With these cranes, Cadeler will be capable of installing offshore foundations and next generation wind turbines for its future offshore wind projects worldwide.

Huisman Leg Encircling Cranes are characterised by their lightweight, yet robust crane designs, with a high level of reliability, energy efficiency, and a limited tail swing, making them ideal for the construction of offshore wind farms.

The scope of work for Huisman consists of the design, engineering and construction of the two LECs at its production facility in Zhangzhou, China. The cranes will be commissioned at COSCO’s shipyard in Qidong, China, where the X-class vessels will be built.

Also read: Demand for offshore cranes prompts Huisman to double slew bearing production capacity

Features of the Huisman Leg Encircling Crane

- A fully electrically driven system results in high positioning accuracy, reduced maintenance and high reliability.

- The optimised energy grid reduces energy consumption.

- The in-house developed slew bearing system provides highly reliable and accurate positioning of the crane.

- The boom’s unique design makes it stiff and lighter in weight.

- Stiff construction of the boom leads to reduced motion at the crane tip.

- The small tail swing allows for optimised utilisation of free deck space.

X-class vessels

The X-class wind turbine installation vessels are to enter service in three years’ time. Cosco will build the duo for USD 651 million. The first will start work for turbine supplier Siemens Gamesa immediately after delivery, scheduled for the third quarter of 2024. The ship will assist with the transport and installation of 100 14-MW wind turbines for RWE’s Sofia wind farm in the British part of the Dogger Bank.

Also read: Cadeler orders next level offshore wind installation vessels

The vessels will have a deadweight of 17,600 tonnes and a deck space of 5600m2. The vessels will be able to transport and install seven complete 15MW turbine sets per load or five sets of 20+MW turbines, cutting down the number of trips needed for each project, thus accelerating installation speed and minimizing the carbon footprint.

A shore power connection, which is expected to reduce fuel consumption by up to fifteen per cent, will be installed on the ship, as well as fuel efficient engines and optimised engine sizing. A battery pack is to reduce fuel consumption during crane operations and DP manoeuvring. The X-class will also include technology for the regeneration of power from the jacking system and cranes.

Also read: GustoMSC designs used for giant offshore wind installation ships for Cadeler