(Mars 201908) A loaded tanker was at anchor awaiting berthing instructions. During the course of the day, routine work was planned in the engine room.

One job involved cutting and grinding a dismantled galvanised 1 inch pipe in the workshop. A toolbox meeting was held and the angle grinders were prepared, one for cutting and one for grinding.

Once the pipe was cut, the fitter positioned the pipe in a vice to grind the cut end. Shortly after he began to work the grinding disc shattered into fragments. Although the guard was fitted, some of the fragments hit the fitter’s left hand, which was protected only by a thin glove. He sustained a deep open cut.

First aid was applied immediately and the victim was later sent ashore for treatment.

Company Investigation

The company investigation found, among other things:

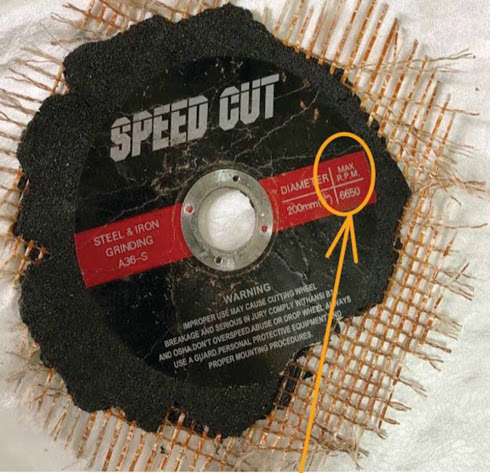

- The grinding disc was designed for a maximum of 6,650rpm, but the grinder was designed to rotate at 8,500rpm, nearly 22% faster than the permitted speed of the grinding disc.

- Before starting the job, information on the angle grinder’s design speed and the manufacturer’s instructions were not checked to verify correct use of the equipment.

- Although the grinder’s protection guard was in place, it was not at the correct angle to afford proper protection.

As indicated by the arrow, the max rpm of the grinding disc was 6650 rpm.

Lessons Learned

- Angle grinders should be marked with their design specifications to help crew check them easily against the discs in use.

- The RPM rating of the disc or blade must be equal to or higher than that of the angle grinder.

- Guards should be adjusted to deflect flying particles away from operator. The guard between the operator and the wheel should be at an angle of 180°.

- Hand protection is essential when grinding. Only robust leather gloves are acceptable.

- Cutting wheels or discs should not be used for grinding jobs, nor should grinding wheels be used for cutting jobs.

- Wheels should be used solely for the specific material and purpose for which they are designed, and always according to the manufacturer’s recommendations.

- The British Abrasives Federation recommends using abrasive discs that comply with standard EN 12413:2007+A1. The standard stipulates that discs must be marked with a date of expiry that is no more than three years after the date of manufacture.

- Wheels worn small through use should be discarded and never used on smaller machines.

Editor’s note: Grinding presents several risks of severe injury to the hands, body and eyes. Some past MARS reports of grinder injuries include 201772, 201725, 201624, 201243, 200882, 200831.

MARS Reports

This is one of the February MARS Reports that are part of Report Number 316. A selection of this Report has also been published in SWZ|Maritime’s March issue.

Acknowledgement

Through the kind intermediary of The Nautical Institute we gratefully acknowledge sponsorship provided by:

American Bureau of Shipping, AR Brink & Associates, Britannia P&I Club, Cargill, Class NK, DNV, Gard, IHS Fairplay Safety at Sea International, International Institute of Marine Surveying, Lairdside Maritime Centre, London Offshore Consultants, MOL Tankship Management (Europe) Ltd, Noble Denton, North of England P&I Club, Sail Training International, Shipowners Club, The Marine Society and Sea Cadets, The Swedish Club, UK Hydrographic Office, West of England P&I Club

Submit a Mars Report

More reports are needed to keep the scheme interesting and informative. All reports are read only by the Mars coordinator and are treated in the strictest confidence. To submit a report, please use the Mars report form and send it to mars@nautinst.org.