SWZ Maritime's September issue is to come out this Friday, but you can read the latest Mars Reports online now.

Mars (Marine Accident Reporting Scheme) Report is one of the regular sections of SWZ Maritime. We will publish all the reports we receive online, as they may prevent other accidents from happening. Mars Reports cover all kinds of maritime incidents such as (near) collisions and groundings, accidents with tools, falling objects injuring crew, accidents with rescue boats and so on.

MARS Report No. 286

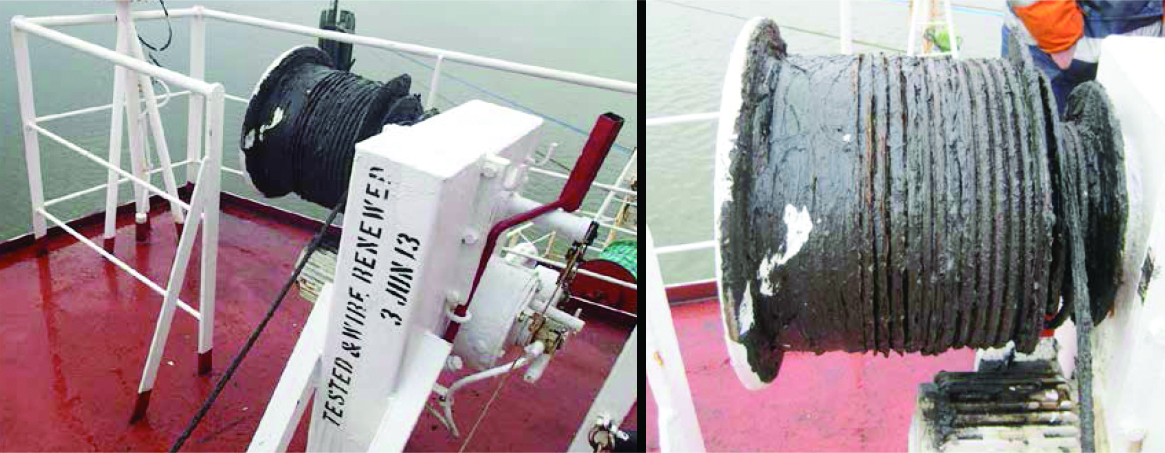

Heavily Greased Wire Rope Less than Adequate: Mars 201639

As edited from official BSU report 364-14

Rescue boat manoeuvres were planned while the vessel was at anchor. Three crew members boarded the rescue boat. After it was loaded, a fourth crew member lowered the boat to the water by lifting the brake. Once in the water the boat was immediately raised again using electric push-buttons acting on the winch. This manoeuvre was repeated several times.

On the final recovery the winch wire rope parted and the boat deployed to the water in free-fall, about 13 metres below. The three crew members were quickly evacuated to a shore hospital. One individual was later pronounced dead and the other two were diagnosed with serious injuries.

Investigation Findings

The accident investigation revealed several important aspects including:

- The wire rope had been rigged incorrectly through the hook, introducing unnecessary stresses.

- The wire rope had a theoretical tensile strength that was approximately 25% less than that recommended by the davit manufacturer.

- Notwithstanding the heavy grease coating, the wire rope was severely corroded at the point of failure.

- The winch automatic shutdown limit switch was found to be defective.

Copious amounts of grease are not always a good sign.

Lessons Learned

- Always rig boat lowering equipment with wire that meets manufacturer’s specifications.

- Copious amounts of grease do not ensure that wire ropes are protected from corrosion, and may in fact hide corrosion deficiencies.

- Corrosion resistance can be increased through the use of galvanized wire in combination with speciality penetrating oils, which have the added benefit of reaching and protecting the wire rope core and keeping the wire clear for proper visual inspection.

- Ensure all limit switches are functional and wires are properly rigged according to manufacturer’s specifications.

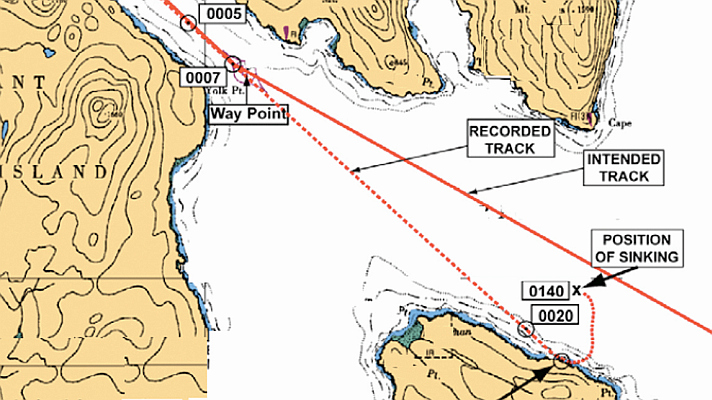

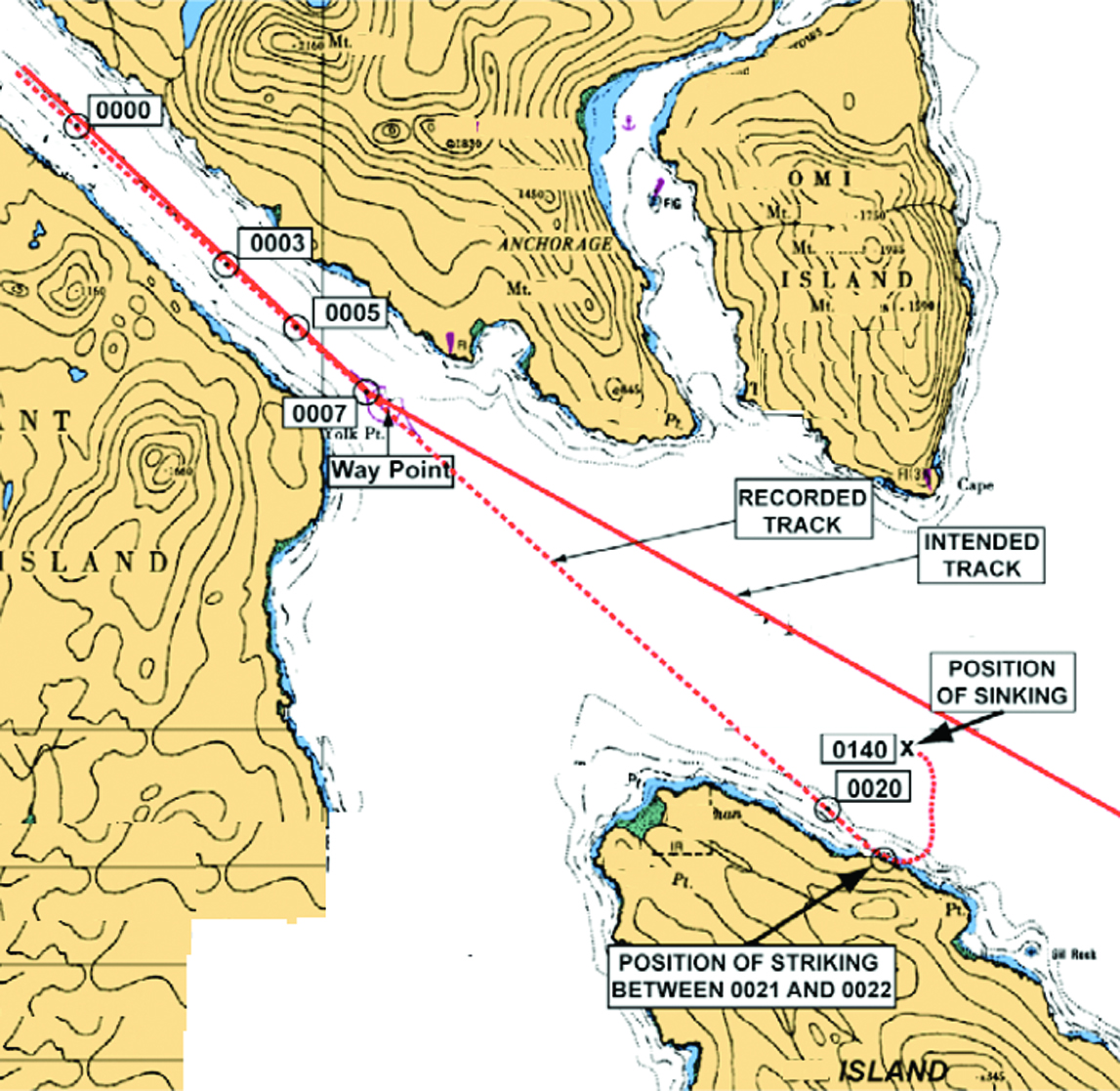

Ferry Hits Island and Sinks: Mars 201640

Edited from official Transport Safety Bureau Canada report M06W0052

A passenger ferry loaded with 22 vehicles and with 59 passengers on board had left port earlier in the evening and was en route in semiprotected VTS coastal waters. In darkness and with good visibility, the vessel was steering on autopilot and the OOW and a quartermaster were on the bridge.

At about midnight, a course adjustment of 4° to port was made to keep the vessel on track. A few minutes later, the OOW reported their position to VTS; he subsequently logged his communication then resumed an ongoing conversation with the quartermaster. At about this time, they encountered a squall of heavy wind and rain, and reduced visibility.

About five minutes later the vessel, making way at about 17 knots, had arrived at a course alteration point, but the 20° alteration to port was not made. As the vessel proceeded, the OOW and quartermaster apparently sat in their chairs next to the radar and forward steering station, respectively, and conversed intermittently for the next 12 minutes. When the vessel was about 13 minutes past the planned course-alteration point, visibility had improved. At about this time both the quartermaster and the OOW saw trees off the starboard bow.

An emergency turn to port was initiated but the vessel nonetheless struck the island then drifted north. The vessel took on water and quickly began sinking. Abandonment of the vessel was necessary. Two persons were reported missing and were subsequently declared deceased.

Investigation Findings

The investigation established, among others, that just prior to the planned course change the OOW’s routine was interrupted by several events that were taking place simultaneously, including:

- Being engaged in a conversation with the quartermaster;

- A rapidly moving squall, causing reduced visibility; and

- A visual alarm indicating a loss of target.

In dealing with the immediate requirements of these events, the OOW was probably distracted at some point between logging the radio communication and ordering the course change. As a result, he believed he had called for and verified the course alteration, but this was not the case. In addition, the electronic chart system (ECS) display was dimmed and the audible alarms had been deactivated, thereby negating any warning that may have been provided by the waypoint alarm.

Lessons Learned

The bridge team did not observe a number of basic principles of safe navigation including:

- Frequent plotting to determine the vessel’s position;

- Calling the senior OOW or the master to the bridge when visibility became reduced;

- Maintaining an effective lookout;

- Locating and identifying the local navigational lights at prominent headlands, and;

- Monitoring the vessel’s progress visually, via radar and with the ECS.

These practices and others would have assisted in keeping the vessel on course or provided the cues necessary to determine that the vessel was not on course.

Editor’s note: As readers can appreciate, many factors are involved in almost every accident, including this one. The OOW appears to have suffered a mental slip a few minutes before he was to alter course. This, in and of itself, was not a fatal flaw. However, the resulting tragic consequences can be attributed to a lack of navigational rigour. Normal best practices would have caught the slip before the vessel hit the island. Another point: many accidents have illustrated that the chair is not an OOW’s best friend. By sitting down one can easily drift off to sleep, daydream or otherwise occupy yourself instead of navigating your vessel.

Insufficient Hold Lighting Can Be Hazardous: Mars 201641

Cargo was being worked using the vessel’s own cranes at night. Port officials noted that, in their opinion, there was inadequate lighting in the hold for the ongoing cargo operations; the vessel crew and master were advised. The situation did not substantially improve so port officials felt obliged to issue a letter of protest to the vessel’s master. Subsequently, cargo cluster lights were repaired and new cargo clusters were purchased.

It has also been observed on some vessels that at times the bulbs of the cargo cluster are either of insufficient wattage or that the vessel does not have a sufficient number of cargo clusters. In other instances the cargo cluster electrical wire is too short and not able to be lowered completely into the hold so as to provide effective lighting within.

Lessons Learned

- It is critical to ensure that there is adequate lighting inside cargo holds as well as on deck for personal safety and efficient handling of cargo.

Hydraulic Hose Hiccups: Mars 201642

Edited from IMCA Safety Flash 22/15

A number of incidents in which there have been contained hydraulic oil spillages on deck have been reported from various sources. Three were hydraulic hose failures and the fourth, a hydraulic tank failure. In all four cases there was no pollution and the oil spillages were contained and cleaned up both quickly and effectively by the crew.

The three hydraulic hose failures all occurred on vessel cranes at the point at which the flexible hoses span the pedestal bearing. This is a weak area for flexible hydraulic hoses due to the nature of the working movement of the crane – chafing and stress to the hoses is much more likely in these areas than in other areas. These hoses are often covered by a protective guard.

While conducting pre-use and planned maintenance inspections it is important that this guard be removed occasionally to ensure a thorough check of the hoses and ferrules can be made. Although from the outside a hose may appear to be in good condition, it can sometimes deteriorate from the inside out. Damage can appear overnight in some cases. This highlights the need to complete pre-use checks of all hydraulics before beginning an operation.

Lessons Learned

- Inspect all fastenings and fittings for corrosion and correct connection;

- Wearing dry gloves, run your hand over all the fastenings and hoses, feel for signs of any hydraulic leaks or damage;

- Visually inspect the hoses for faults or blemishes including any lumps, scars or signs of colour deterioration or internal corrosion;

- Ensure all hoses are free from constraint or abrasion;

- If the hoses need to move in operation ensure they are free to do this;

- Ask whether any measures can be taken to prevent deterioration, such as installing protective guards or additional fixings or supports.

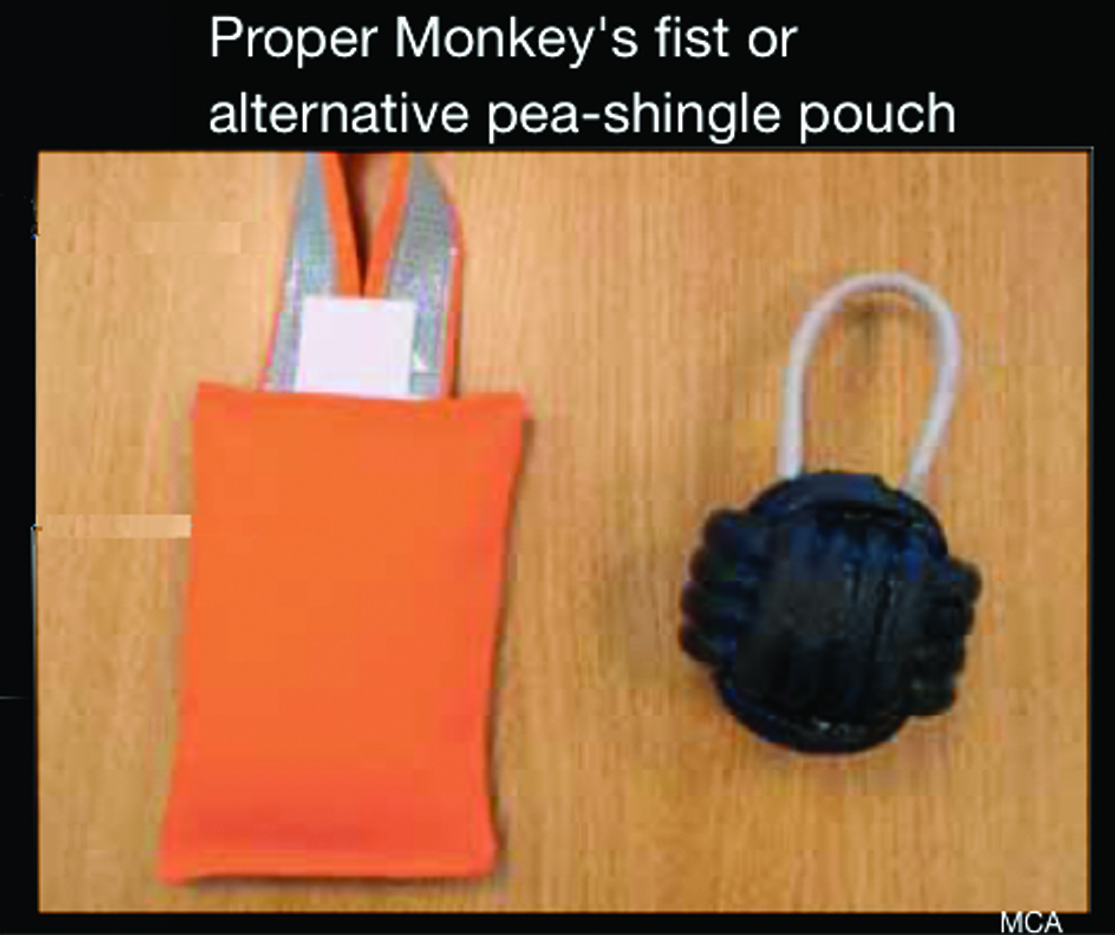

Improvised Monkey’s Fist Throws a Dangerous Punch: Mars 201643

The vessel was approaching port under pilotage and the crew had to send a heaving line to a tug. Unknown to the tug crew, the heaving line had a large steel shackle attached to the end as a weight. Luckily, none of the tug crew was hit when the line was thrown some 10 metres down to the tug.

Lessons Learned

- Attaching weights to a heaving line in lieu of a proper monkey’s fist or even a weight concealed within the monkey’s fist is improper seamanship and could be very dangerous.

Editor’s note: General guidance exists to this effect, such as the United Kingdom’s Maritime and Coastguard Agency publication Code of Safe Working Practices for Merchant Seafarers, 2015 edition. Section 26.3.5 of this publication states: “To prevent personal injury to those receiving heaving lines, the monkey’s fist should be made with rope only and must not contain added weighting material. Safe alternatives include a small high-visibility soft pouch, filled with fast-draining pea shingle or similar, with a weight of not more than 0.5 kg. Under no circumstances is a line to be weighted by items such as shackles, bolts or nuts, or twist locks.”

Pilot Ladder Magnets Dangerously Adrift: Mars 201644

As the pilot boat approached the vessel for pilot boarding, the crew were informed that the ladder was 1 metre too short. The ladder was secured to the vessel’s hull by two magnets and a rope to the accommodation ladder. The vessel’s crew made the appropriate adjustments and re-secured the ladder at the appropriate height. The length of the ladder was now about 6 metres.

When the pilot was approximately 3 metres up the ladder, both magnets on the hull broke free and just missed the top of his helmet. Both magnets stayed attached to the ladder and the pilot managed to climb the last 3 metres without difficulty.

The company investigation found that the crew did not rig the pilot ladder as described in its fleet circular. Also, the incident was not reported to the company by the ship’s crew but was received through a third party.

Lessons Learned

- The master and officers should closely supervise the rigging of pilot ladders. They should also observe the shipping/landing of pilots from ladders to ensure that SOLAS requirements are met.

- Rigging of pilot ladders, with or without magnets, should always be done according to procedures and with a high attention to detail.

- All incidents, even those without consequences, should be reported to the company through the normal ISM procedural process.

Reader’s Comment: Mars 201626 – Enclosed Space Fatality

The first two bullet points are of concern because they mix and match the two processes of purging a tank and then gas-freeing it.

In the MARS report 201626 we can read:

- Normally, inert gas is introduced into the tank to drive out the hydrocarbon content (purging) to a level below the flammable range before replacing the inert gas with fresh air (gas-freeing – ie HC to be at 2% or less). It is not known why this procedure was not carried out in this instance.

- With a HC level of 26% LEL the atmosphere was too rich to allow an explosive condition, but was also too high to support a tank entry without BA gear.

The first bullet would read correctly if the words “by volume” were added after the 2%. (This is the purging, and 2% hydrocarbons by volume equates to 200% of the lower explosive limit (LEL). If you then start gas-freeing and introducing air from that point the mixing of air/hydrocarbon gas is such that you will remain outside the flammable envelope and be safe from an explosion from a source of ignition.)

The second bullet point is simply incorrect as 26% LEL is in fact too lean to allow an explosive condition, not too rich’.

Editor’s note: We are indebted to the reader for these corrections. The errors appear to have been also committed in the official published report.

Reader’s Comment: Mars 201614 – Snapback Slip-up

Please note that high modulus polyethylene (HMPE) line is subject to parting when overheated. The dangers of surging these Class II lines is emphasised in every manufacturer’s safety bulletin, even around a pillar roller fair lead. Without chafing gear, abrasion from external sources slows the outer layers on helical twisted rope, which in turn allows the inner strands to build up heat as they surge at a different speed, causing them to melt. Eventually the rope loses tensile strength and simply pulls apart.

The introduction of pennants that stretch, to lessen the effects of the Class II rigidity on the deck machinery, has now re-introduced snap-back risks for HMPE ropes. The danger is the lack of understanding of the mechanics of these lines and the failure to understand the limitations, especially on abrasion, of these new super lines.

Acknowledgement

Through the kind intermediary of The Nautical Institute we gratefully acknowledge sponsorship provided by:

American Bureau of Shipping, AR Brink & Associates, Britannia P&I Club, Cargill, Class NK, DNV, Gard, IHS Fairplay Safety at Sea International, International Institute of Marine Surveying, Lairdside Maritime Centre, London Offshore Consultants, MOL Tankship Management (Europe) Ltd, Noble Denton, North of England P&I Club, Sail Training International, Shipowners Club, The Marine Society and Sea Cadets, The Swedish Club, UK Hydrographic Office, West of England P&I Club

Submit a Mars Report

More reports are needed to keep the scheme interesting and informative. All reports are read only by the Mars coordinator and are treated in the strictest confidence. To submit a report please use the Mars report form and send it to mars@nautinst.org.